Siphoning type tea boiler

A siphon type, tea set technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of long tea brewing time, long power consumption time, high noise, etc., and achieves convenient and fast use, cost saving, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, a preferred embodiment of the present invention will be described with reference to the accompanying drawings.

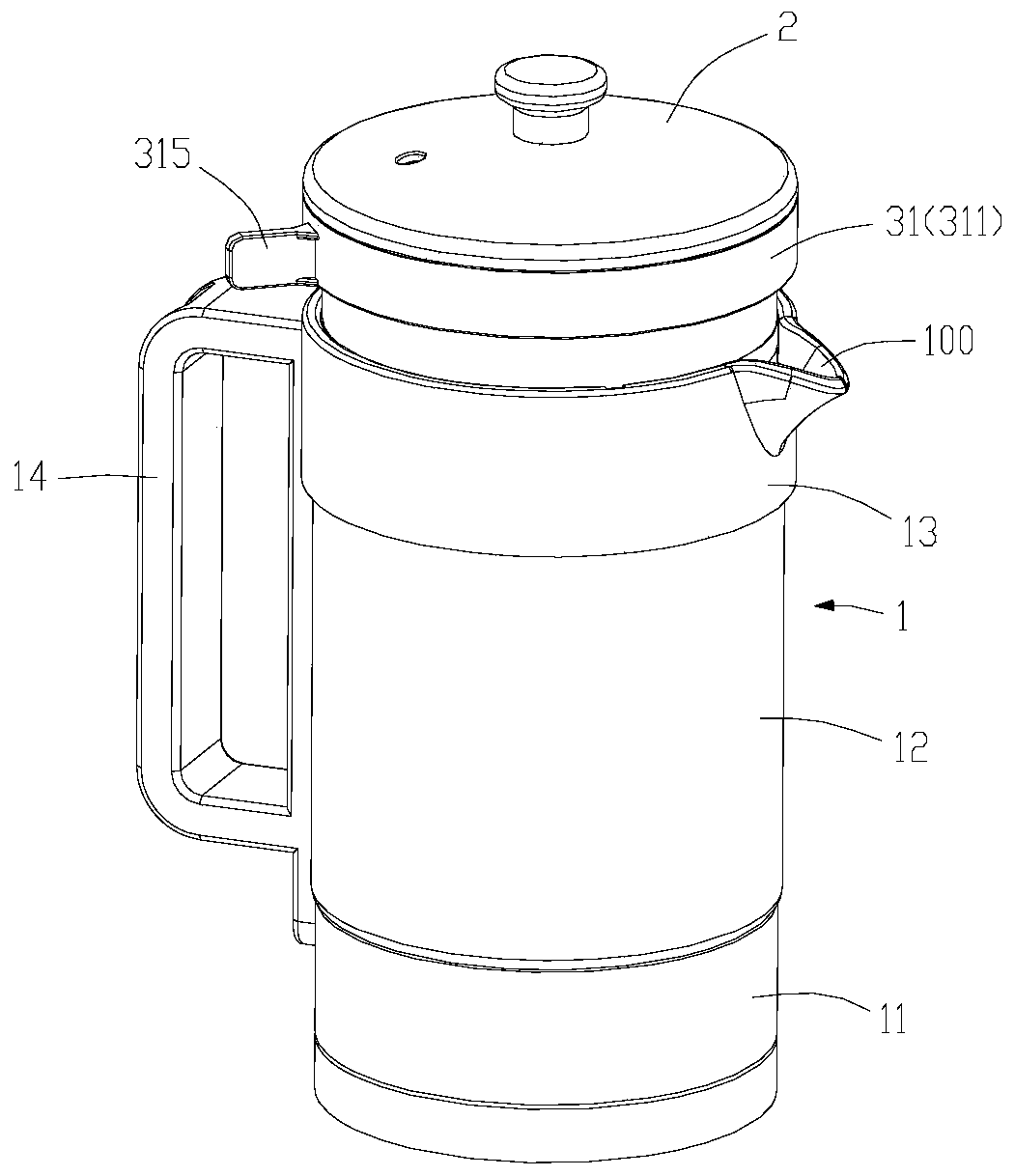

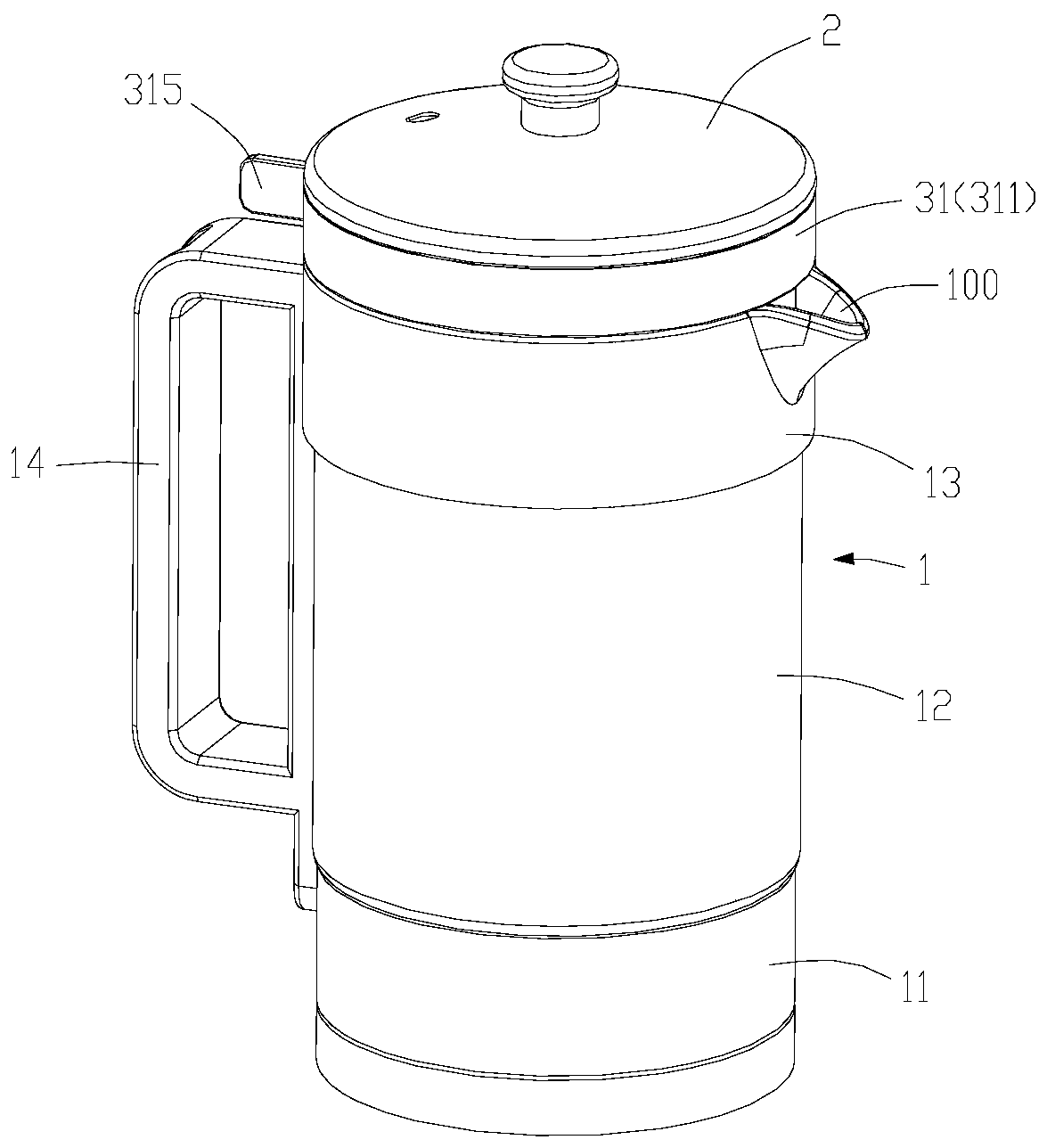

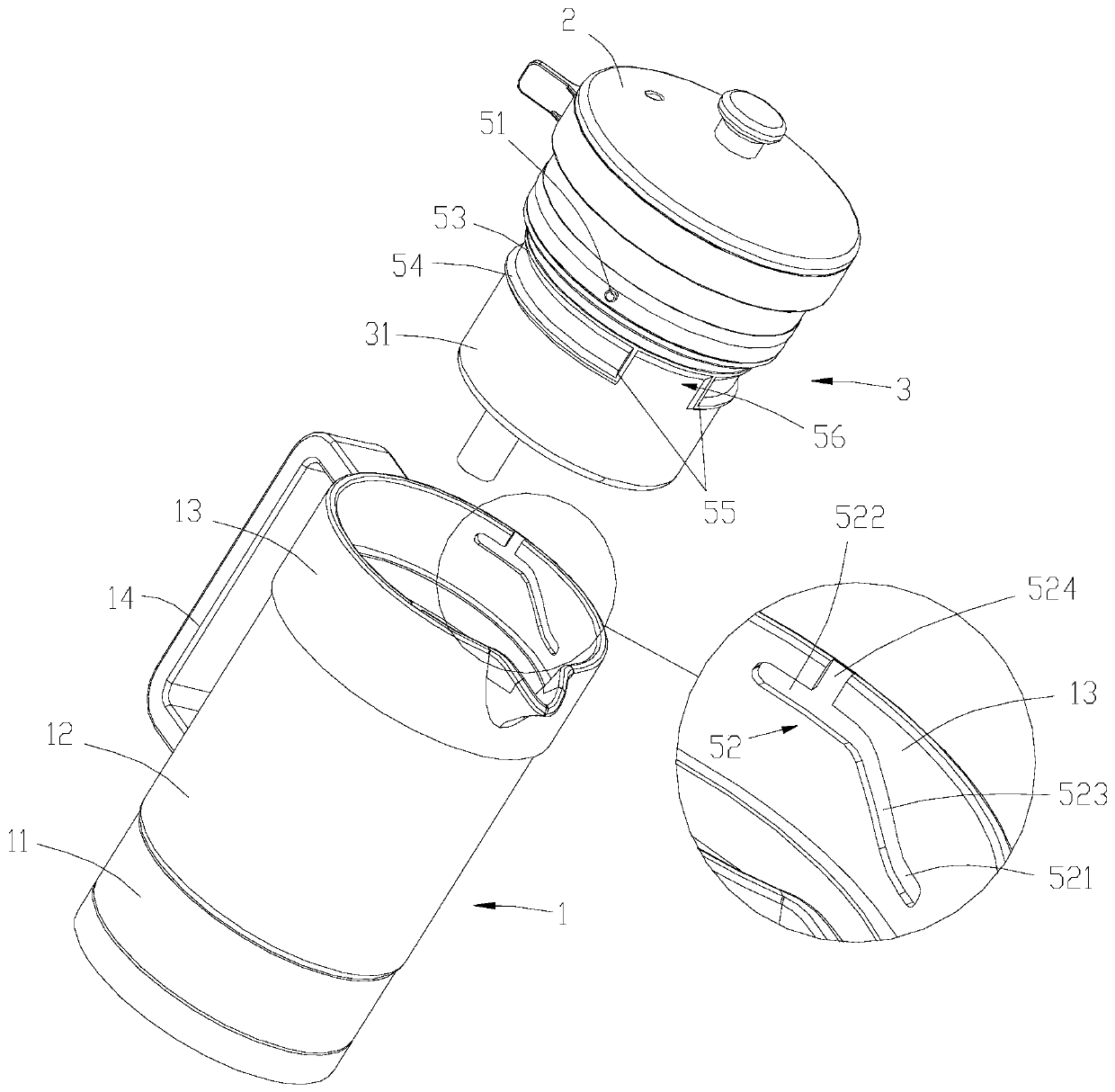

[0028] See Figure 1 to Figure 8 , This embodiment provides a siphon tea maker, including a kettle body 1, a kettle lid 2, and a brewing assembly 3. The kettle body 1 is provided with a kettle cavity 10 with an upper side opening, and the upper portion of the kettle body 1 is provided with a communicating In the water outlet 100 of the pot cavity 10, the bottom of the pot body 1 is provided with a heating element 111. In a specific embodiment, the pot body 1 includes a pot bottom 11, an annular body 12, and a support ring 13. The kettle body 12 is detachably mounted on the upper end of the kettle bottom 11, the support ring 13 is detachably mounted on the top end of the kettle body 12, and the lower ring is provided with a slot 131, the kettle The upper end of the body 12 is inserted into the slot 131, the outer side of the kettle body 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com