Puttying robot

A technology for scraping putty and robots, applied in the direction of buildings, building structures, etc., can solve the problem of non-vertical walls, and achieve the effect of increasing benefits, ensuring flatness and firmness, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

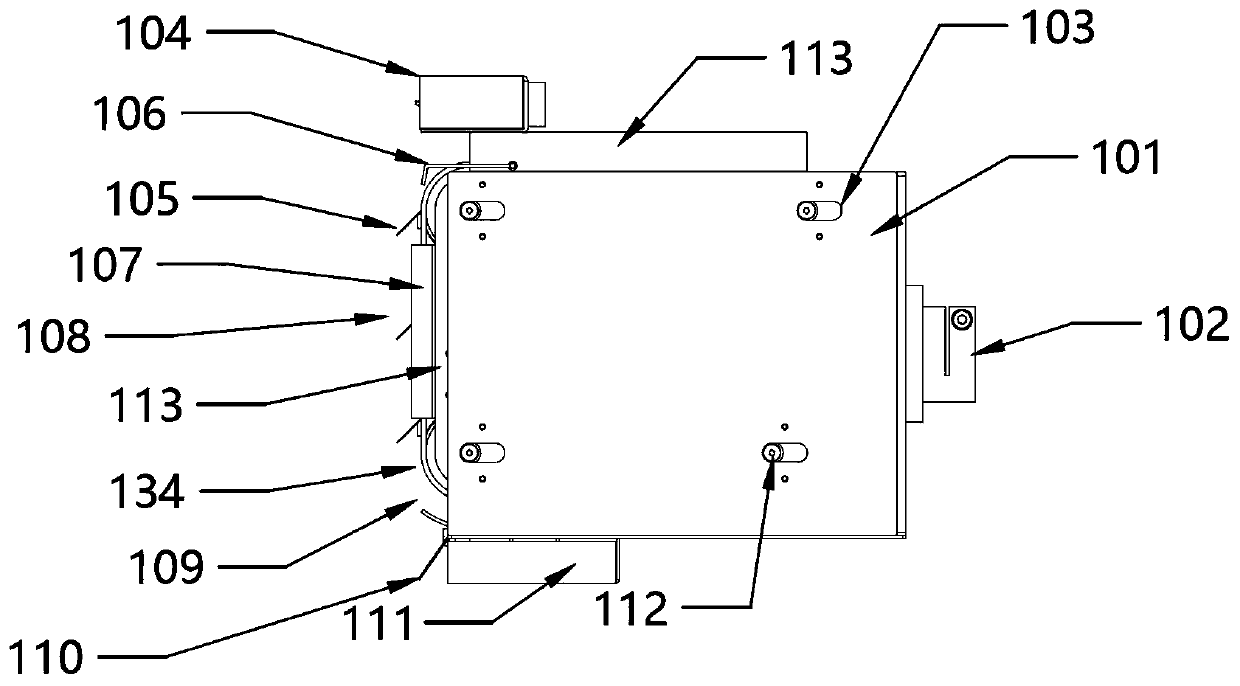

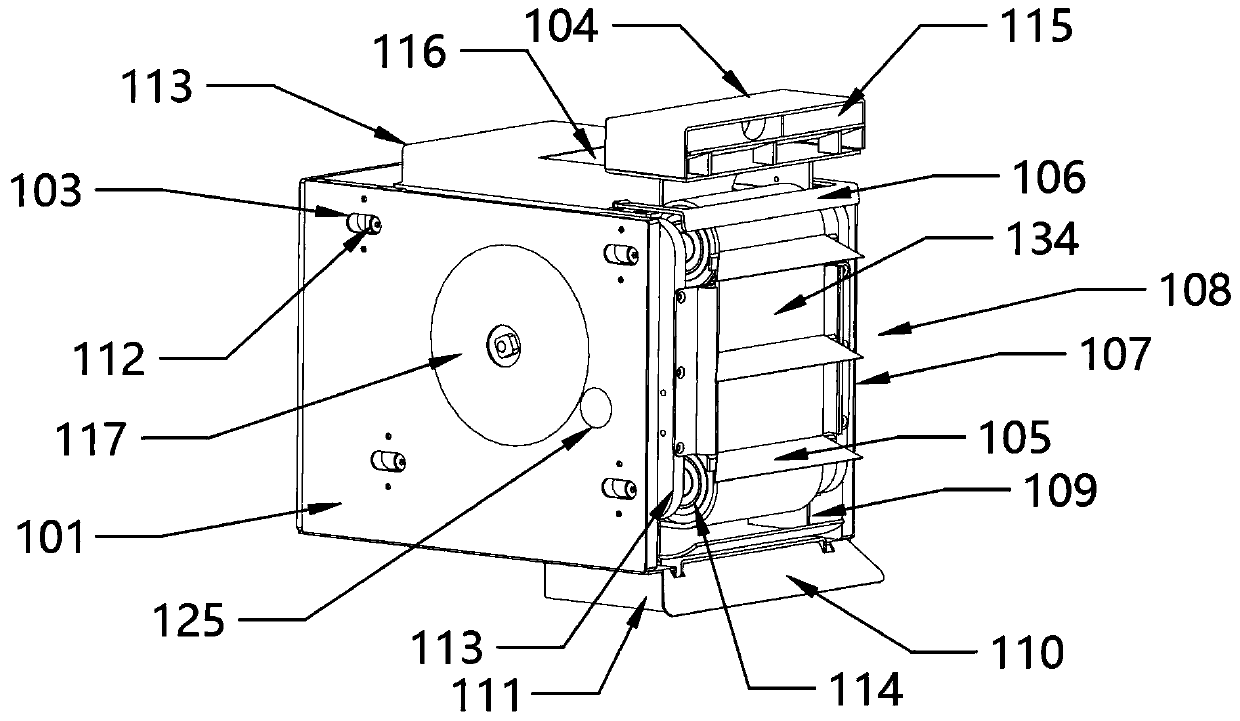

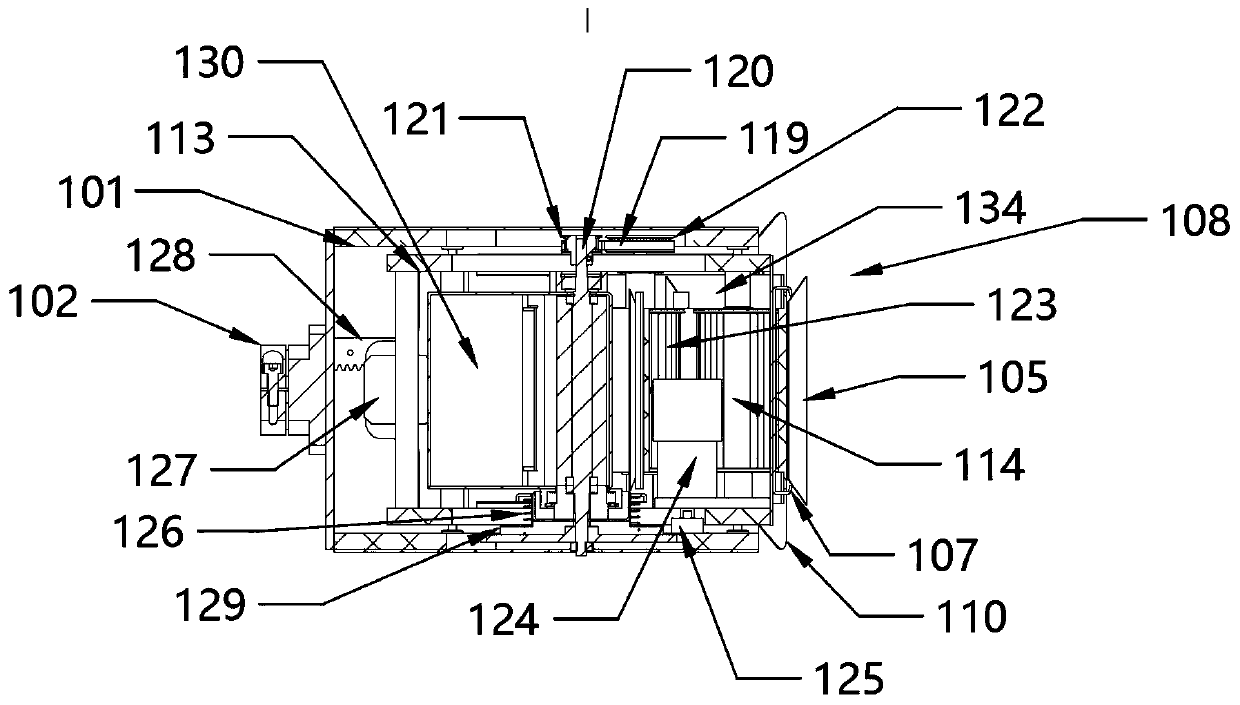

[0036] see figure 1 – Figure 5 , the putty scraping robot provided in this embodiment is composed of an outer frame system and an inner frame execution system. The front and rear horizontal movement adjustment under the support and fixation of the frame system can realize the verticality of the wall after the wall putty construction.

[0037] The outer frame system includes an outer frame box body 101, a flange 102 arranged in the middle of the back of the outer frame box body 101, four track windows 103 respectively arranged on the left and right sides of the outer frame box body 101, and an outer frame box body. The rack 128 arranged in the middle of the rear of the bottom of the body 101 .

[0038]The inner frame implementation system includes: the inner frame box body 113, and the putty scraping rotary assembly 134 arranged in the first half of the inner frame box body 113, and the material storage box assembly 130 arranged in the second half, and also arranged in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com