Composite transport case

A technology for transport boxes and box covers, applied in the field of composite transport boxes, which can solve the problems of easily damaged packaging cartons, unsafe protection and loss of canned products, and achieve the effect of reducing the contact area and improving the protective effect of the package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

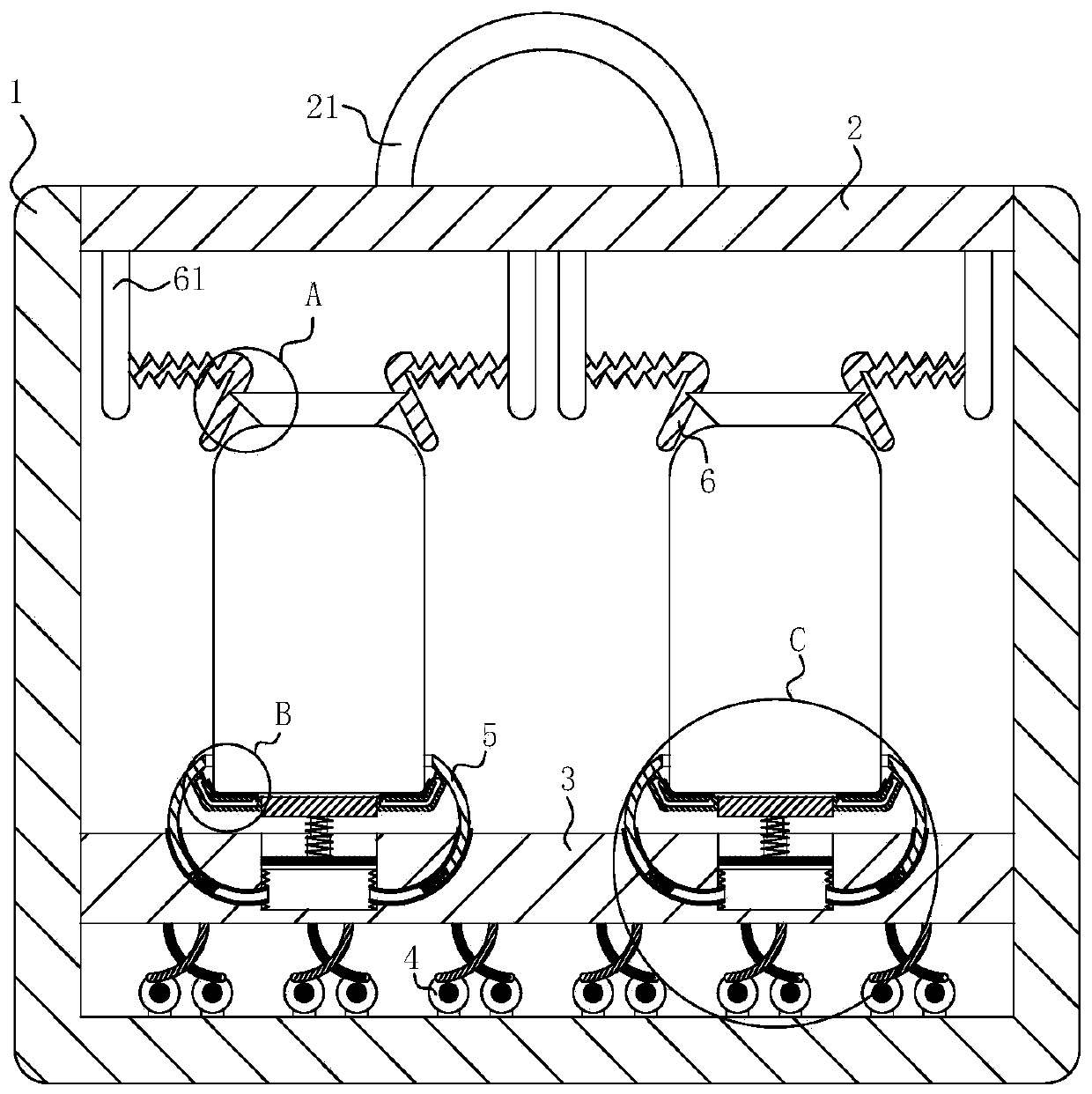

[0021] use Figure 1-Figure 6 A composite transport box according to one embodiment of the present invention will be described as follows.

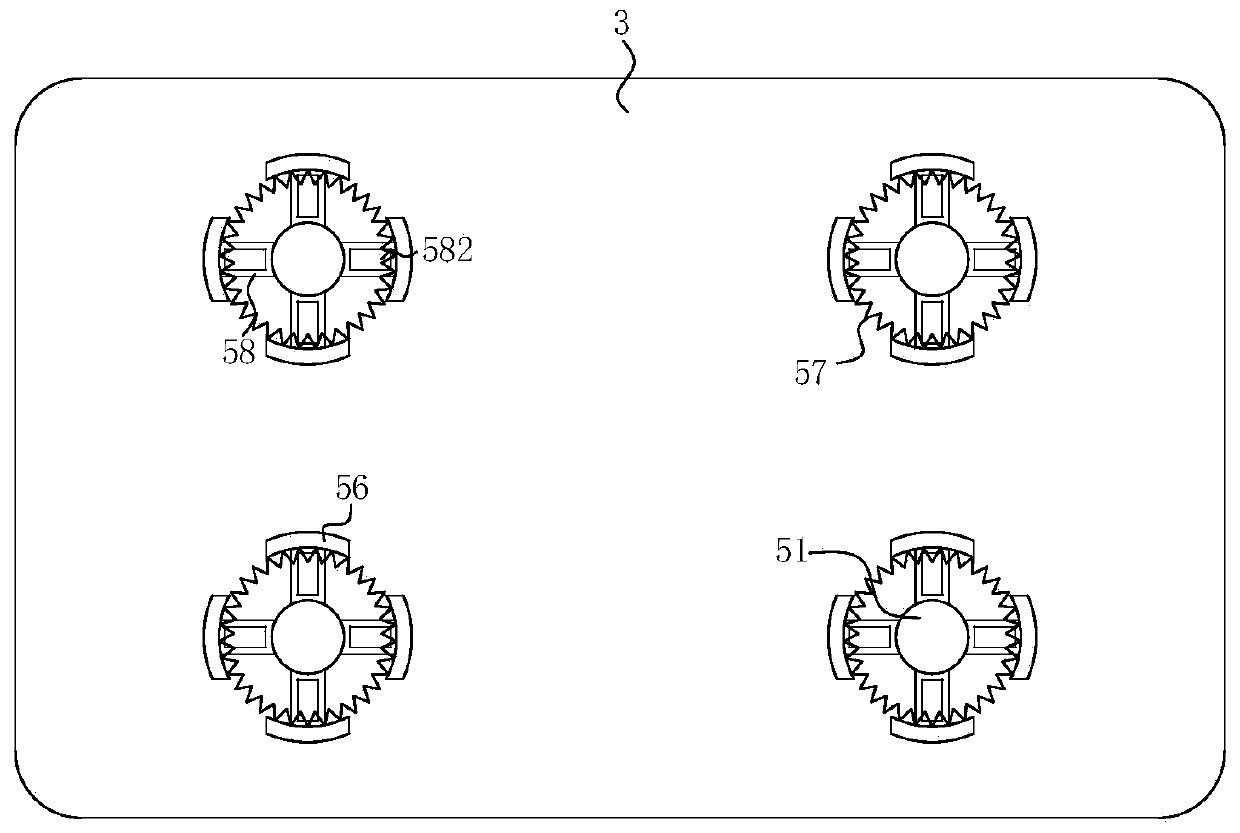

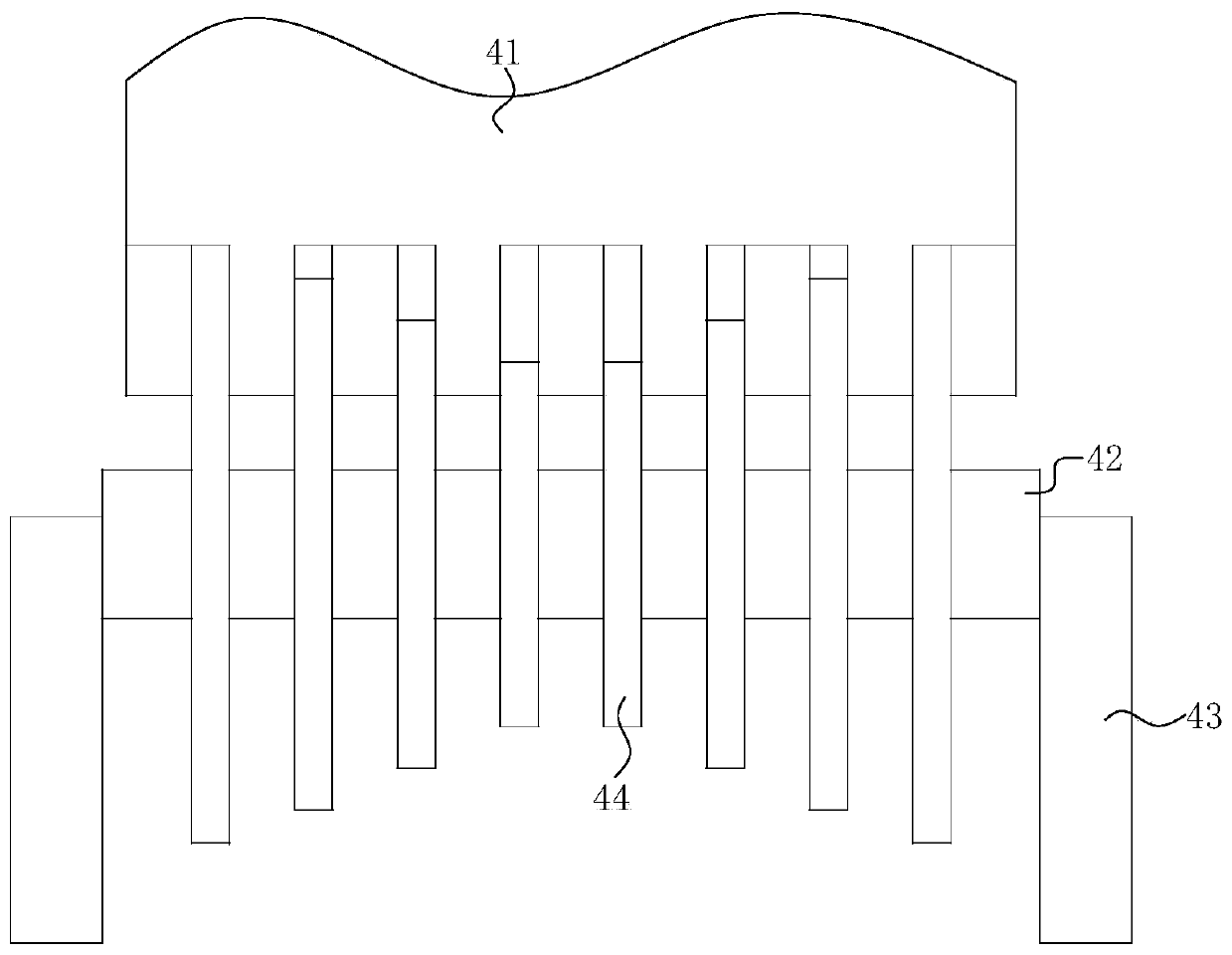

[0022] Such as Figure 1-Figure 6 As shown, a composite transport case of the present invention includes a case body 1, a case cover 2, a mounting plate 3, a shock absorbing mechanism 4, a first fixing mechanism 5 and a second fixing mechanism 6; the case cover 2 slides Installed on the upper end of the box body 1, the upper surface of the box cover 2 is fixedly equipped with a pull rod 21; the pull bar 21 is used for installation and removal of the box cover 2; the lower end of the box body 1 is slidingly installed with a mounting plate 3; the installation The plate 3 is provided with a first fixing mechanism 5; the first fixing mechanism 5 is provided with four, and the first fixing mechanism 5 includes a pressure bearing plate 51, an elastic telescopic rod 52, a bottom plate 53, a rubber air bag 54, and an arc tube 55 and an arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com