Epoxy floor troweling machine

An epoxy floor and trowel technology, applied in the direction of roads, buildings, building structures, etc., can solve the problems of different casting times, inability to adapt to the concrete surface, affecting the troweling effect of the floor, etc. , Increase the protective effect of wrapping, increase the effect of smoothing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

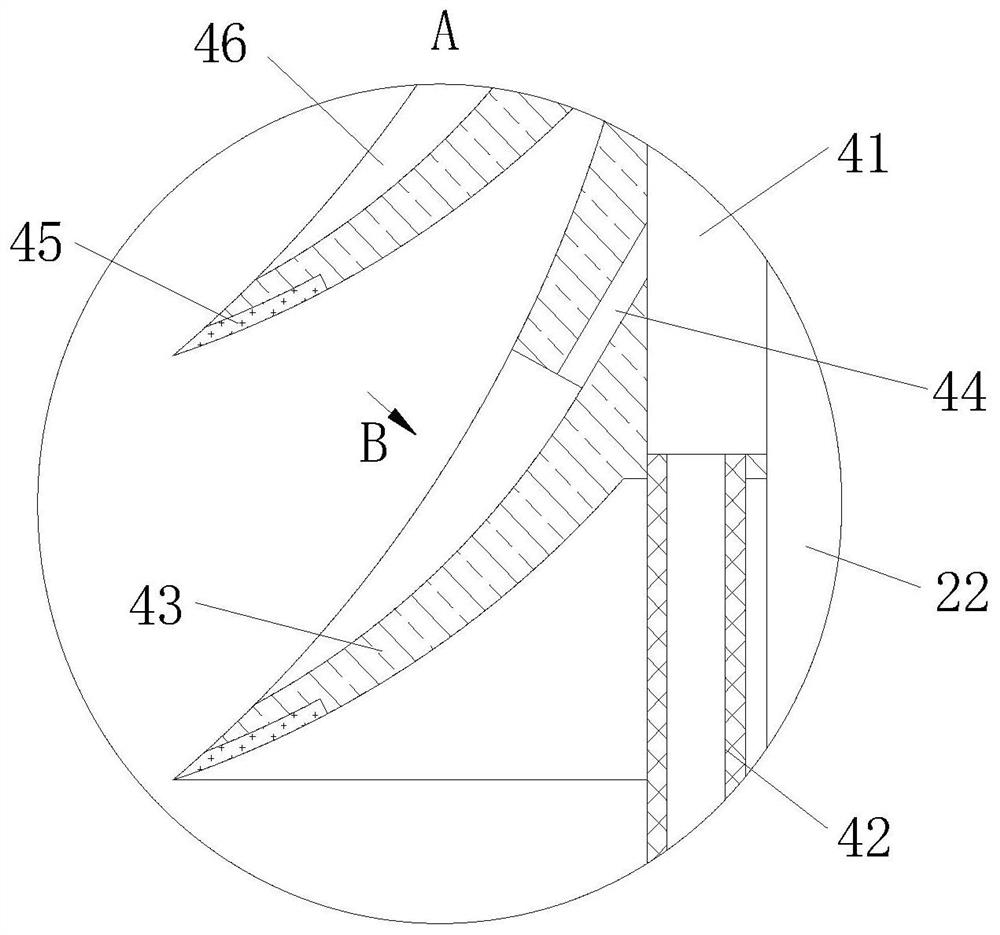

[0030] As an embodiment of the present invention, a group of elastic sawtooth tips 3 are evenly distributed on one side of the wave groove 25, and the ends of the sawtooth tips 3 are inclined in a direction away from the second hole 27; A sawtooth groove 31 is provided; the corrugated groove 25 and the corresponding position of the sawtooth groove 31 are fixedly connected with an arc-shaped magnetic piece 32, and the outer circumference of the sliding column 26 is the same as the magnetic pole on the side adjacent to the magnetic piece 32; the said sawtooth groove 31 is far away from the wave One side of the groove 25 is provided with an isosceles trapezoidal chute 33, and the two ends of the chute 33 communicate with the two ends of the wave groove 25; the side of the chute 33 near the second hole 27 is hinged with a shrapnel 35 by a pin 34, and the shrapnel The length of 35 is greater than the width of the chute 33, the free end of the shrapnel 35 is lapped on the edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com