Slurry smoothing device and leveling machine

A slurry and screed technology, applied in the processing of building materials, roads, buildings, etc., can solve the problems of affecting the strength of concrete structures, and the joints are easy to become crack sources, and achieve the effect of improving the quality of troweling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

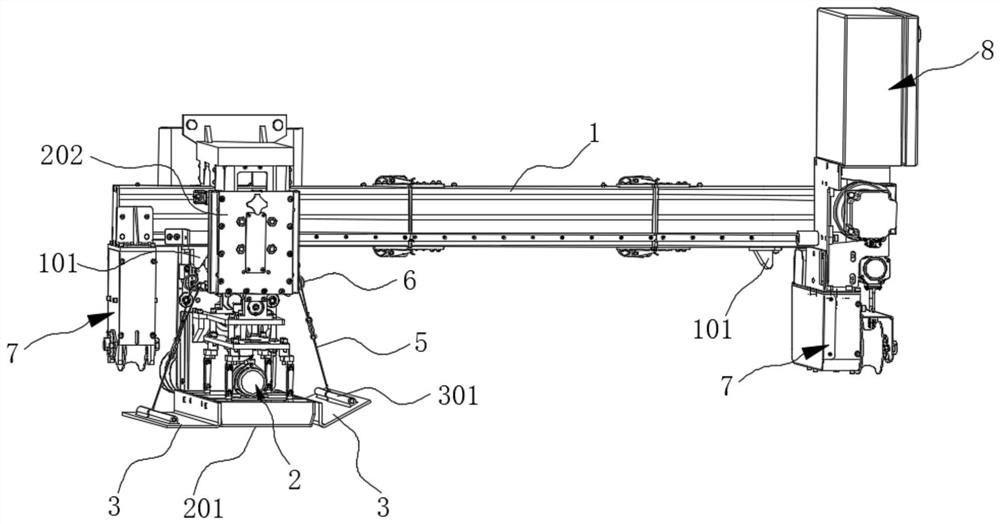

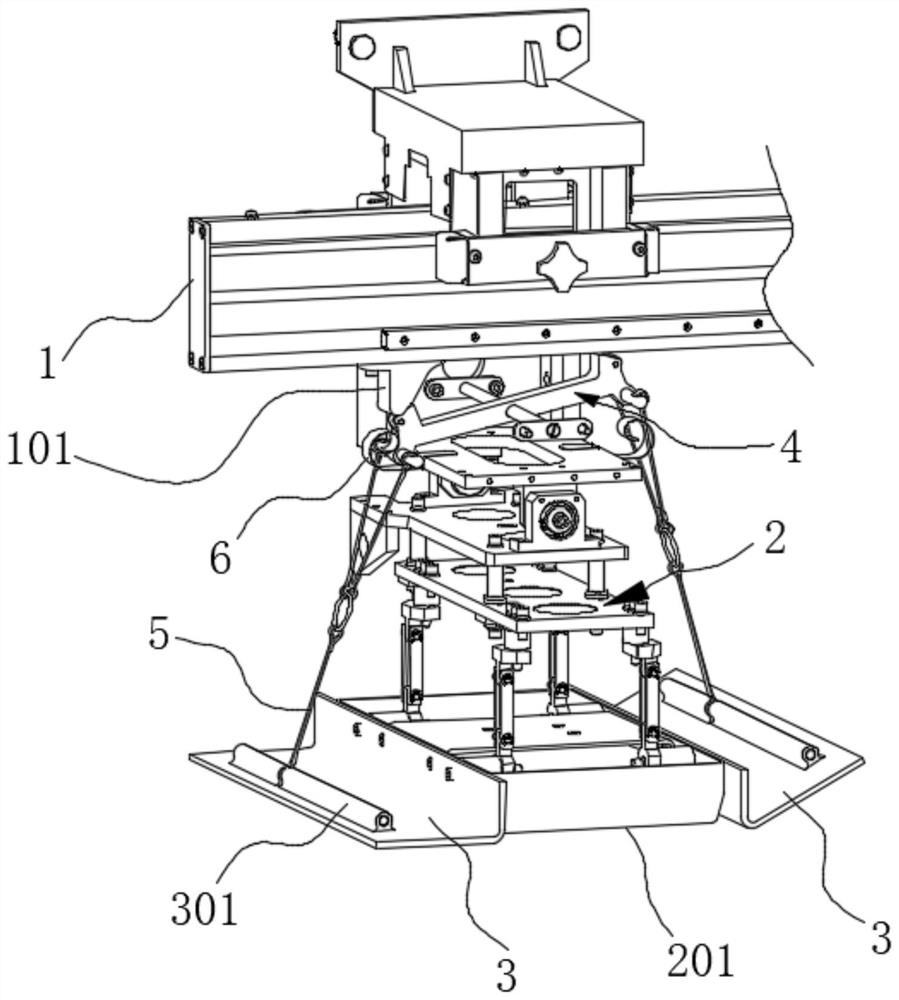

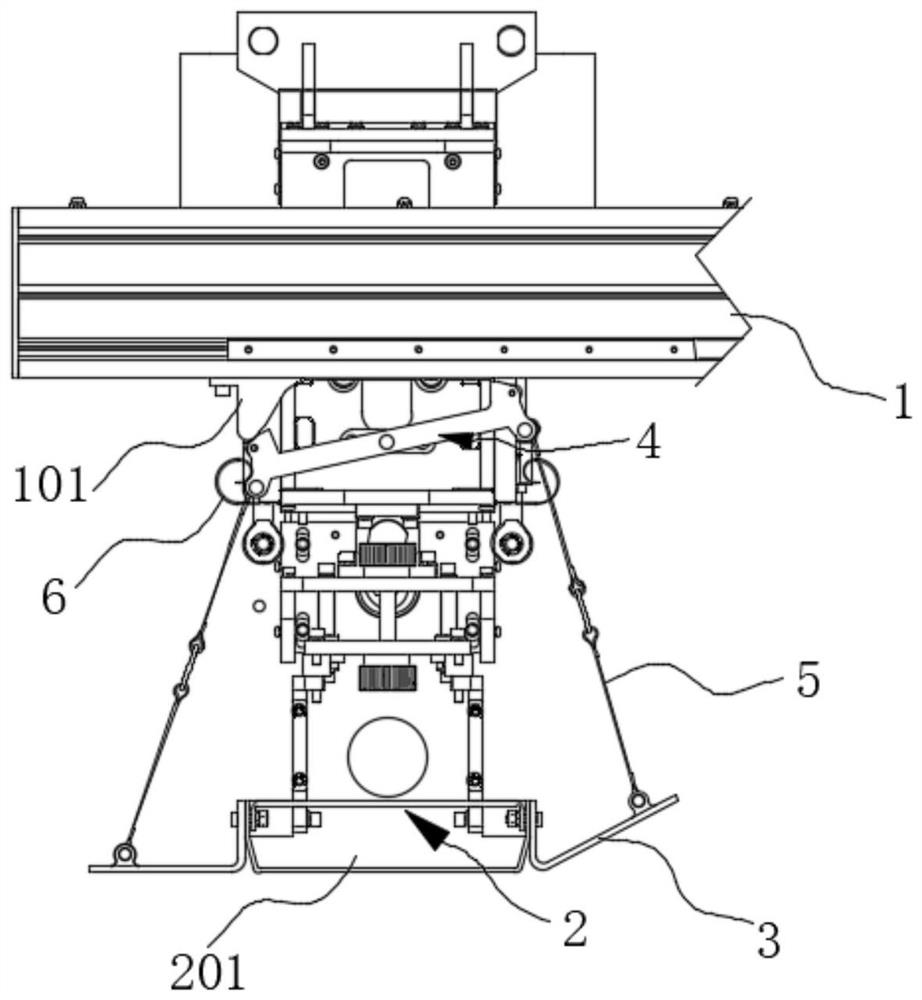

[0051] like Figure 1-Figure 6As shown, this embodiment provides a slurry leveling device for leveling the concrete floor of a residential building, including a beam 1, a leveling component 2 and a leveling component. Wherein, the leveling assembly 2 is slidably connected with the beam 1 and can slide along the beam 1. The leveling assembly 2 includes a screed plate 201 located at the bottom, and the leveling assembly is connected with the leveling assembly 2 and slides together. The leveling assembly includes a troweling plate 3. The screed plate 3 is arranged on the side of the screed plate 201 along the extension direction of the beam 1, and the width dimension of the screed plate 3 in the direction perpendicular to the extension direction of the beam 1 is larger than the width dimension of the screed plate 201 in this direction. When the screed 201 moves along the extension direction of the beam 1 and level the concrete, the trowel 3 arranged behind the screed 201 further ...

Embodiment 2

[0064] like figure 1 As shown, the present embodiment provides a leveling machine, including the slurry leveling device provided in Embodiment 1, and also includes a running mechanism 7 arranged at both ends of the beam 1 of the slurry leveling device, and the running mechanism 7 includes traveling wheels and A travel motor connected to the travel wheel in rotation, the travel motor is used to drive the travel wheel to rotate, so that the crossbeam 1 travels in the horizontal direction to adjust the working position.

[0065] Further, the leveling machine also includes an electric control assembly 8, which is electrically connected to the leveling drive motor and the traveling mechanism 7, and the electric control assembly 8 can be a centralized or distributed controller, for example, it can be a A single single-chip microcomputer, such as an STM32 single-chip microcomputer, can also be composed of distributed multi-block single-chip microcomputers. The control program can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com