Cooling water jacket, cooling device and manufacturing method of cooling water jacket

A technology for cooling water jackets and cooling devices, applied in cooling/ventilation devices, electromechanical devices, manufacturing motor generators, etc., can solve the problems of expensive equipment investment and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

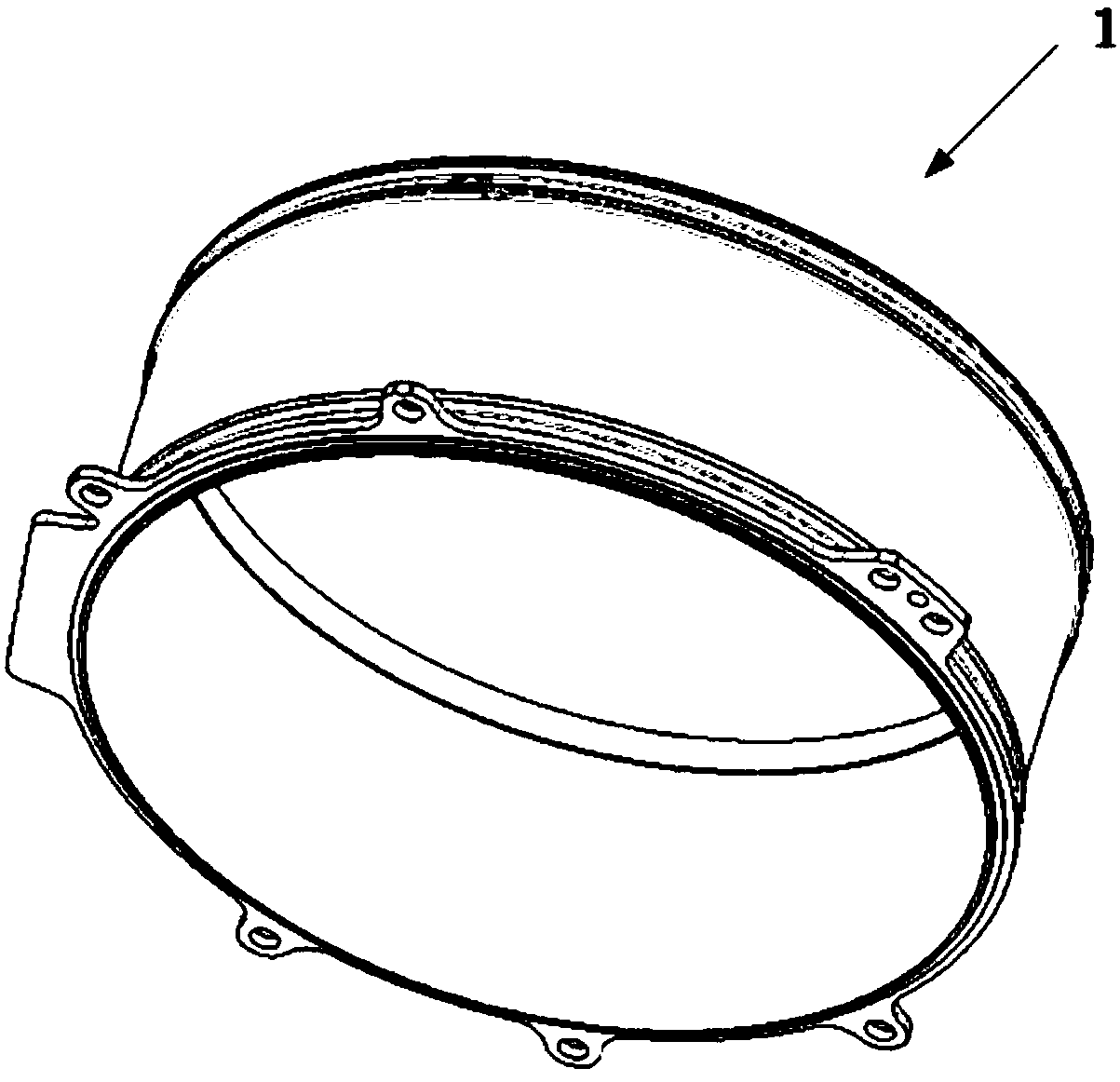

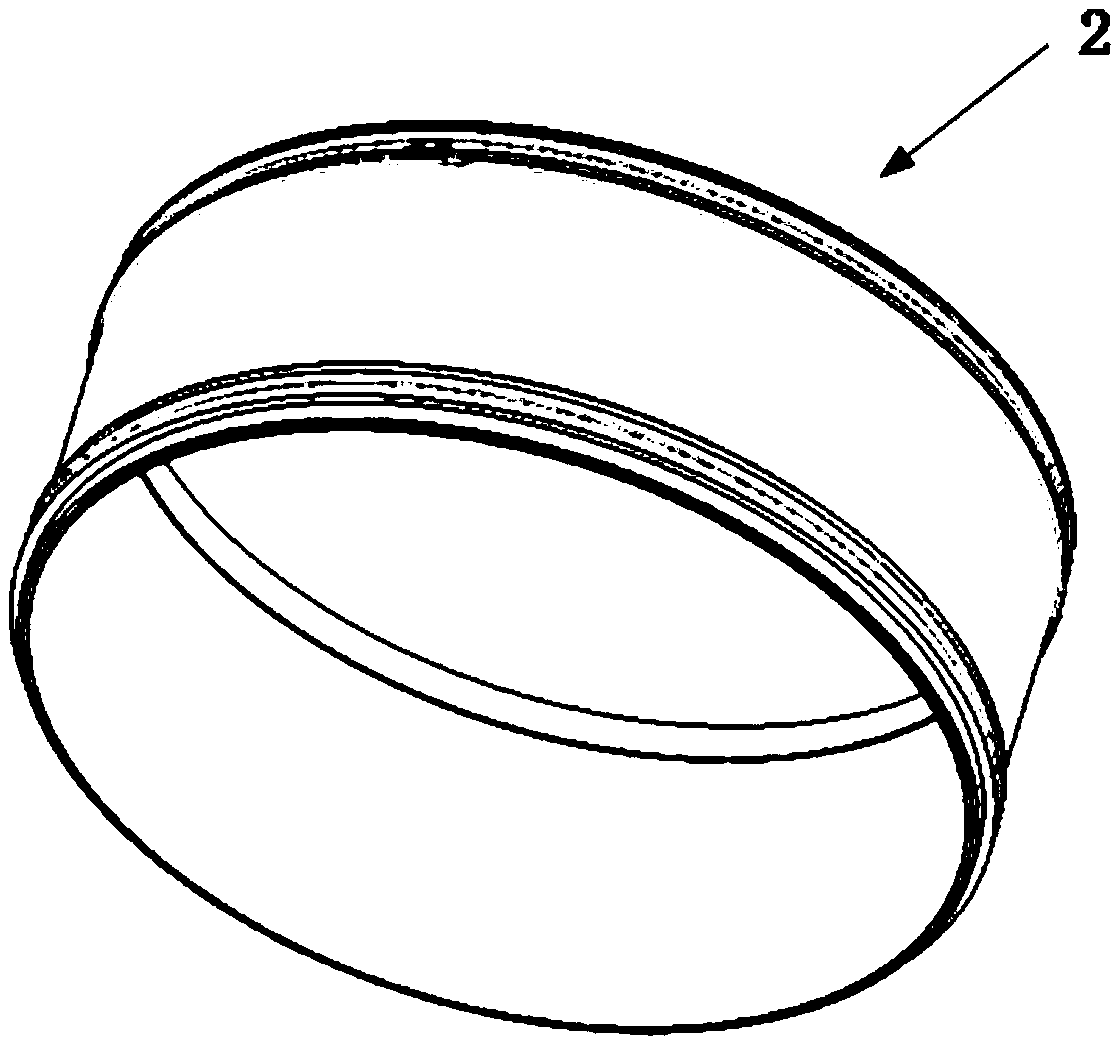

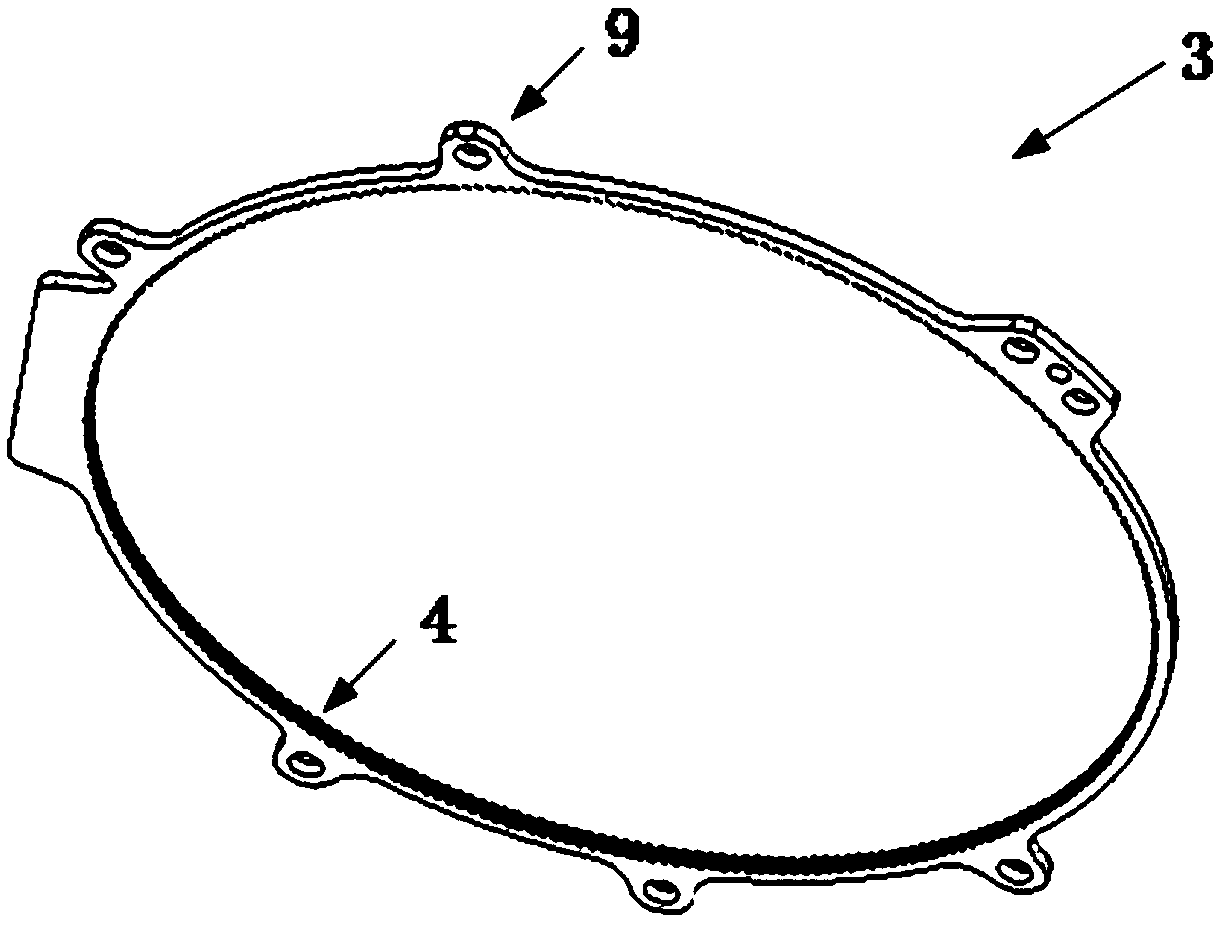

[0018] figure 1 The cooling water jacket 1 according to the embodiment of the present invention is shown, and the cooling water jacket 1 is composed of figure 2 Shown sleeve piece 2 and image 3 The shown fixing member 3 is assembled in two parts.

[0019] Such as figure 2 As shown, the sleeve member 2 is cylindrical, which is prepared from a metal pipe blank through a turning process. Pipes similar in size and thickness to the final product can be used to process the casing part 2. During the turning process, according to assembly or functional requirements, one or more ring grooves and bosses can be formed on the outer peripheral side of the sleeve member 2 by turning. The outer peripheral side of the sleeve member 2 may cooperate with the housing of the cooling device to form a channel for guiding the cooling liquid. Such as Figure 4 As shown, a boss 5 is formed on the outer side of one end of the sleeve member 2 through a turning process, and the sleeve member 2 narrows r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com