Adjusting temperature at location within target volume

A technology of target volume and temperature measurement, applied in the direction of temperature control, temperature control, control/regulation system using multiple sensors, can solve the problem of unacceptable temperature difference of isolation container, and achieve the effect of accurate and rapid temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

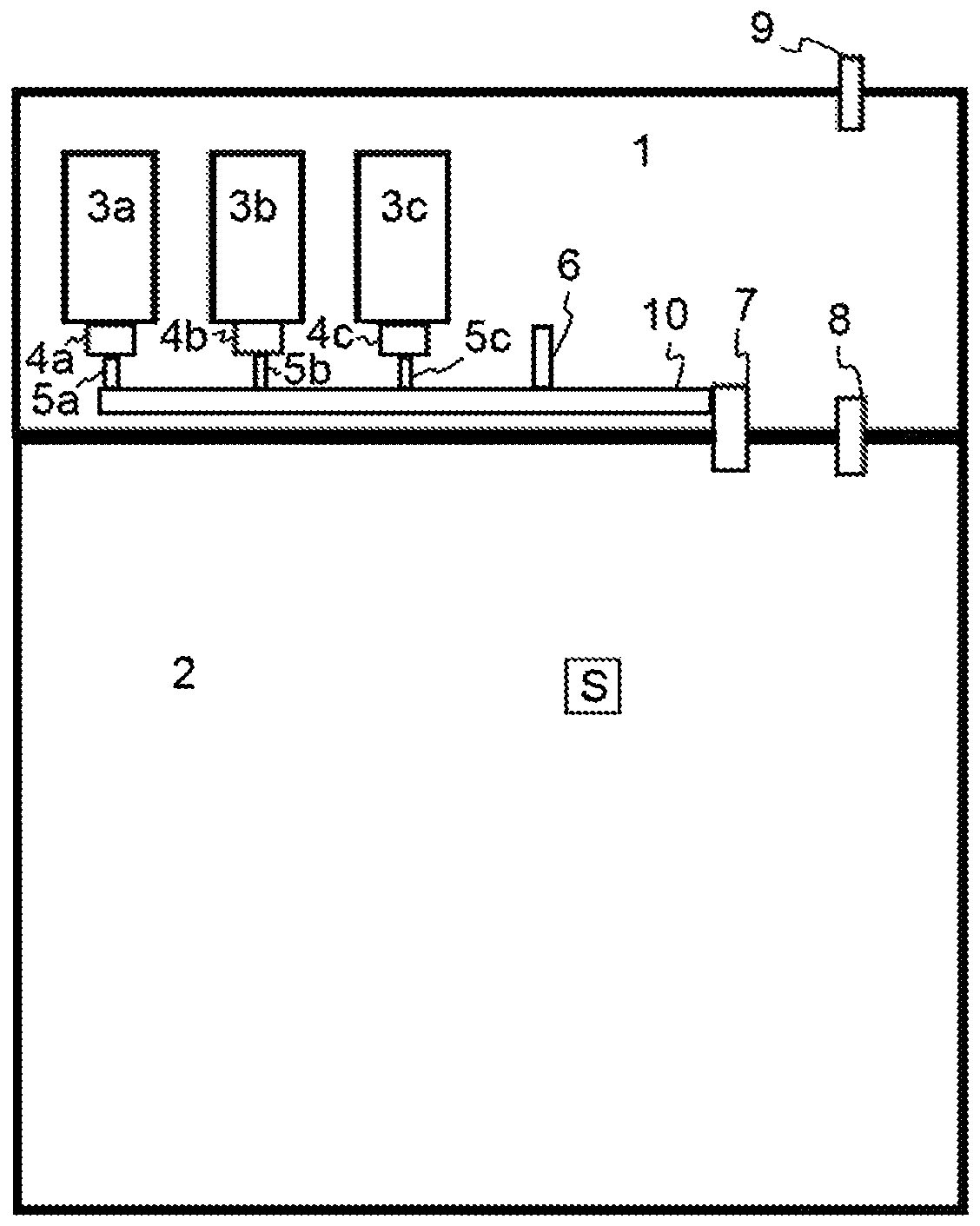

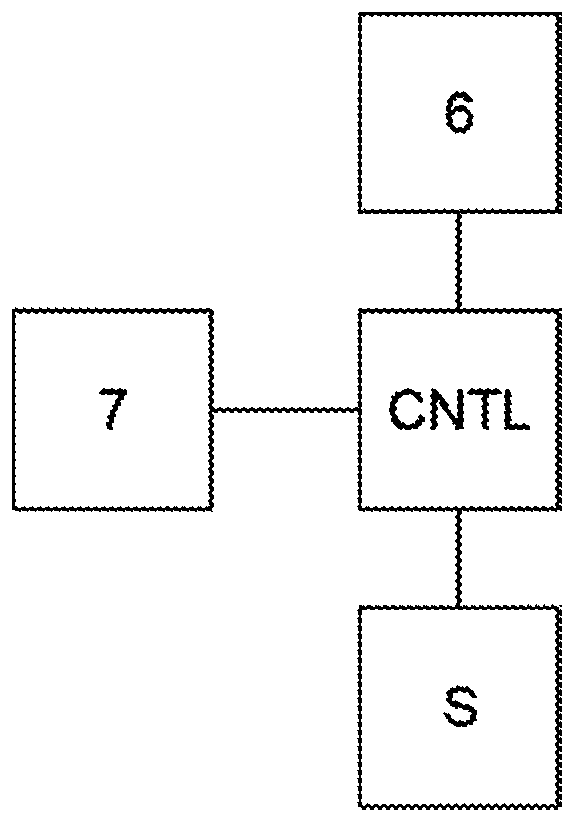

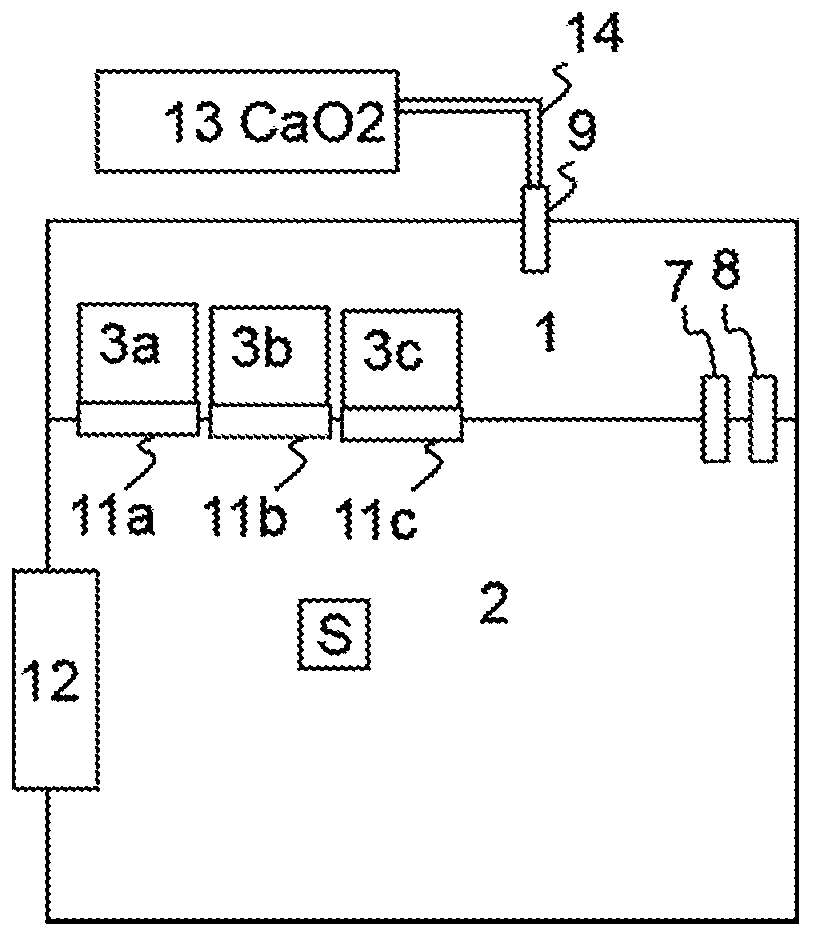

[0033] Various embodiments herein relate to temperature regulation within a target volume. Temperature regulation may include cooling and / or heating the target volume by gas flow.

[0034] Certain embodiments describe the use of dry ice as a coolant. Dry ice is carbon dioxide (CO 2 ) in solid form. Dry ice sublimates at -78.5°C at Earth's atmospheric pressure. During sublimation of solid dry ice, the dry ice changes directly from the solid phase to the gas phase without passing through an intermediate liquid phase. In the following, sublimated dry ice refers to dry ice in the gaseous phase. The extreme coldness of solid dry ice makes it dangerous to handle solid dry ice without protection due to freezing (frostbite) leading to burns. Although outgassing from dry ice is generally not very toxic, outgassing from dry ice can lead to hypercapnia due to accumulation in confined spatial locations.

[0035] Certain embodiments describe heating a target volume (eg, a storage con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com