Welding method of laser tailor-welded plate

A welding method and laser tailor welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as easy generation of defects, and achieve the effect of improving the utilization rate of steel and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

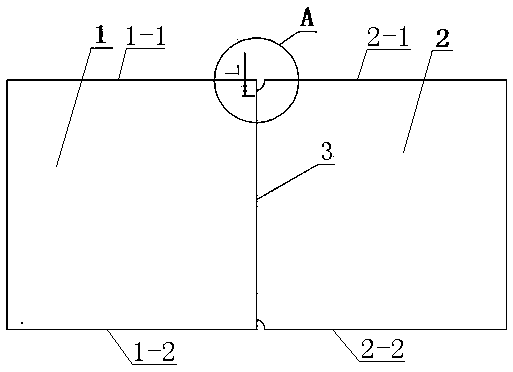

[0017] Such as figure 1 The laser tailor-welded blank is welded to the first steel plate 1 and the second steel plate 2 through the weld 3, the first steel plate 1 in this embodiment is a cold rolled plate with a thickness of 2.2 mm and 780DP, and the second steel plate 2 is 590DP, a cold-rolled plate with a thickness of 1.6 mm, the thickness of the first steel plate 1 is greater than the thickness of the second steel plate 2, and the first steel plate 1 and the second steel plate 2 are laser tailor-welded into a laser tailor-welded plate. The welding method includes the following step:

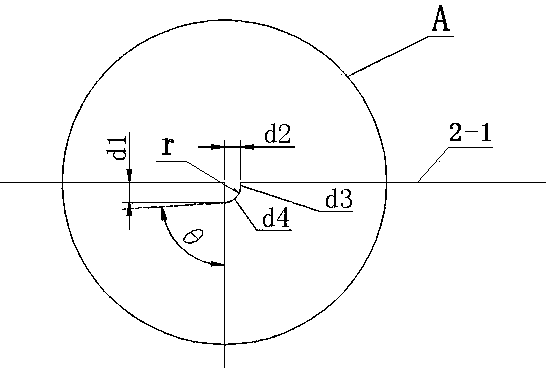

[0018] A. Blanking and blanking: Firstly, the first slab and the second slab are punched into the first steel plate 1 and the second steel plate 2 with two lateral sides and two longitudinal sides, and two of the first steel plate 1 The transverse sides are transverse side 1-1 and transverse side 1-2 respectively. The two transverse sides of the second steel plate 2 are transverse side 2-1 and t...

Embodiment 2

[0023] Such as figure 1 The laser tailor-welded blank is welded to the first steel plate 1 and the second steel plate 2 by welding seam 3. The first steel plate 1 in this embodiment is a cold rolled plate with a thickness of 780DP and a thickness of 2.2 mm, and the second steel plate 2 is 590DP, a cold-rolled plate with a thickness of 1.6 mm. The thickness of the first steel plate 1 is greater than that of the second steel plate 2. The welding method of the first steel plate 1 and the second steel plate 2 by laser welding to form a laser tailor-welded plate includes the following step:

[0024] A. Blanking and blanking: Firstly, the first slab and the second slab are punched into the first steel plate 1 and the second steel plate 2 with two lateral sides and two longitudinal sides, and two of the first steel plate 1 The transverse sides are transverse side 1-1 and transverse side 1-2 respectively. The two transverse sides of the second steel plate 2 are transverse side 2-1 and tr...

Embodiment 3

[0029] Such as figure 1 The laser tailor-welded blank is welded to the first steel plate 1 and the second steel plate 2 by welding seam 3. The first steel plate 1 in this embodiment is a cold rolled plate with a thickness of 780DP and a thickness of 2.2 mm, and the second steel plate 2 is 590DP, a cold-rolled plate with a thickness of 1.6 mm. The thickness of the first steel plate 1 is greater than that of the second steel plate 2. The welding method of the first steel plate 1 and the second steel plate 2 by laser welding to form a laser tailor-welded plate includes the following step:

[0030] A. Blanking and blanking: Firstly, the first slab and the second slab are punched into the first steel plate 1 and the second steel plate 2 with two lateral sides and two longitudinal sides, and two of the first steel plate 1 The transverse sides are transverse side 1-1 and transverse side 1-2 respectively. The two transverse sides of the second steel plate 2 are transverse side 2-1 and tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com