Dry-type air-core reactor with interchangeable splicing structure

An air-core reactor, dry-type technology, applied in the direction of transformer/inductor coil/winding/connection, circuit, electrical components, etc., can solve the problems of inconvenient processing, waste of materials and labor costs, etc., to achieve accurate circumference, avoid Waste, reduce the effect of operating temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

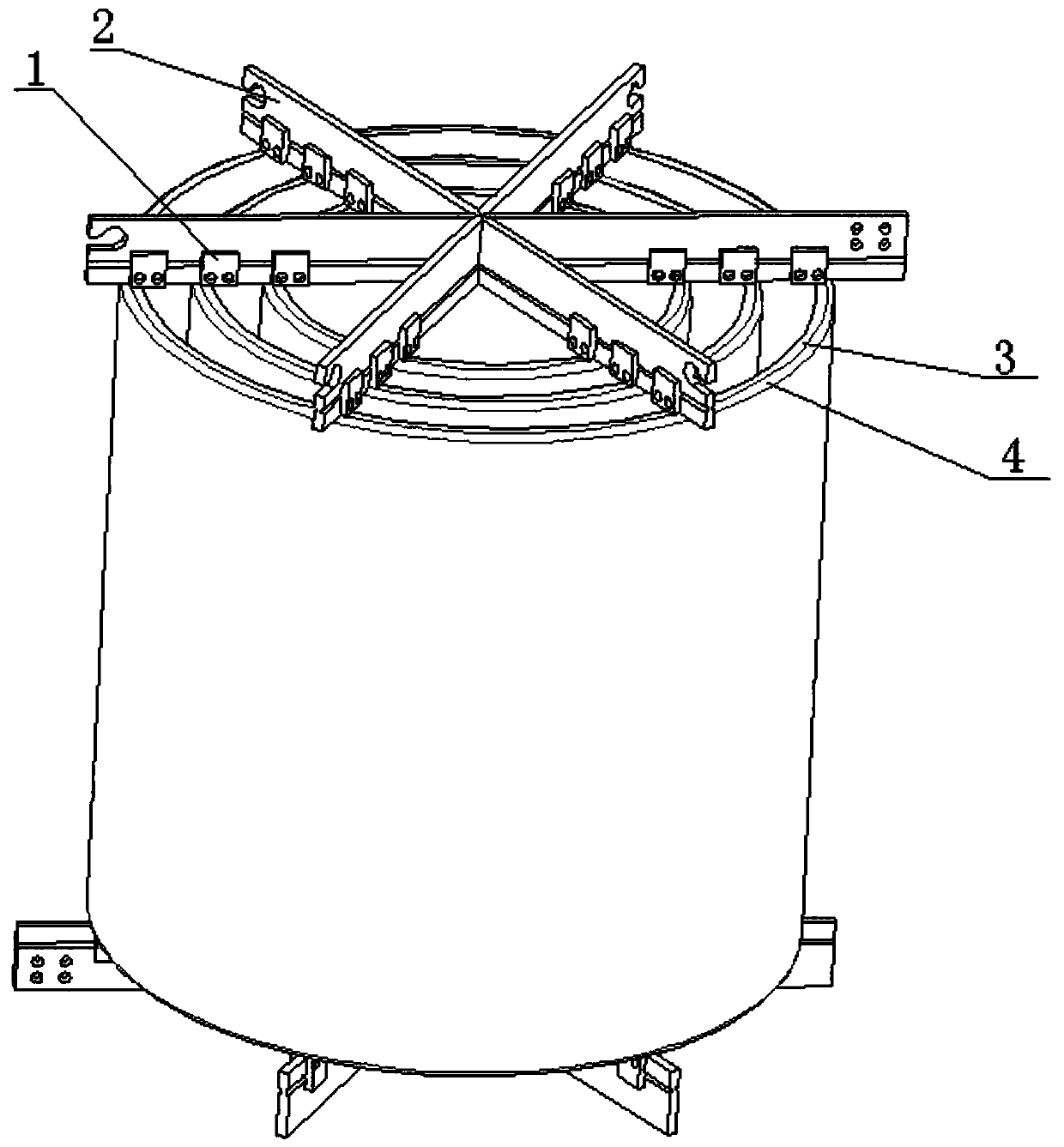

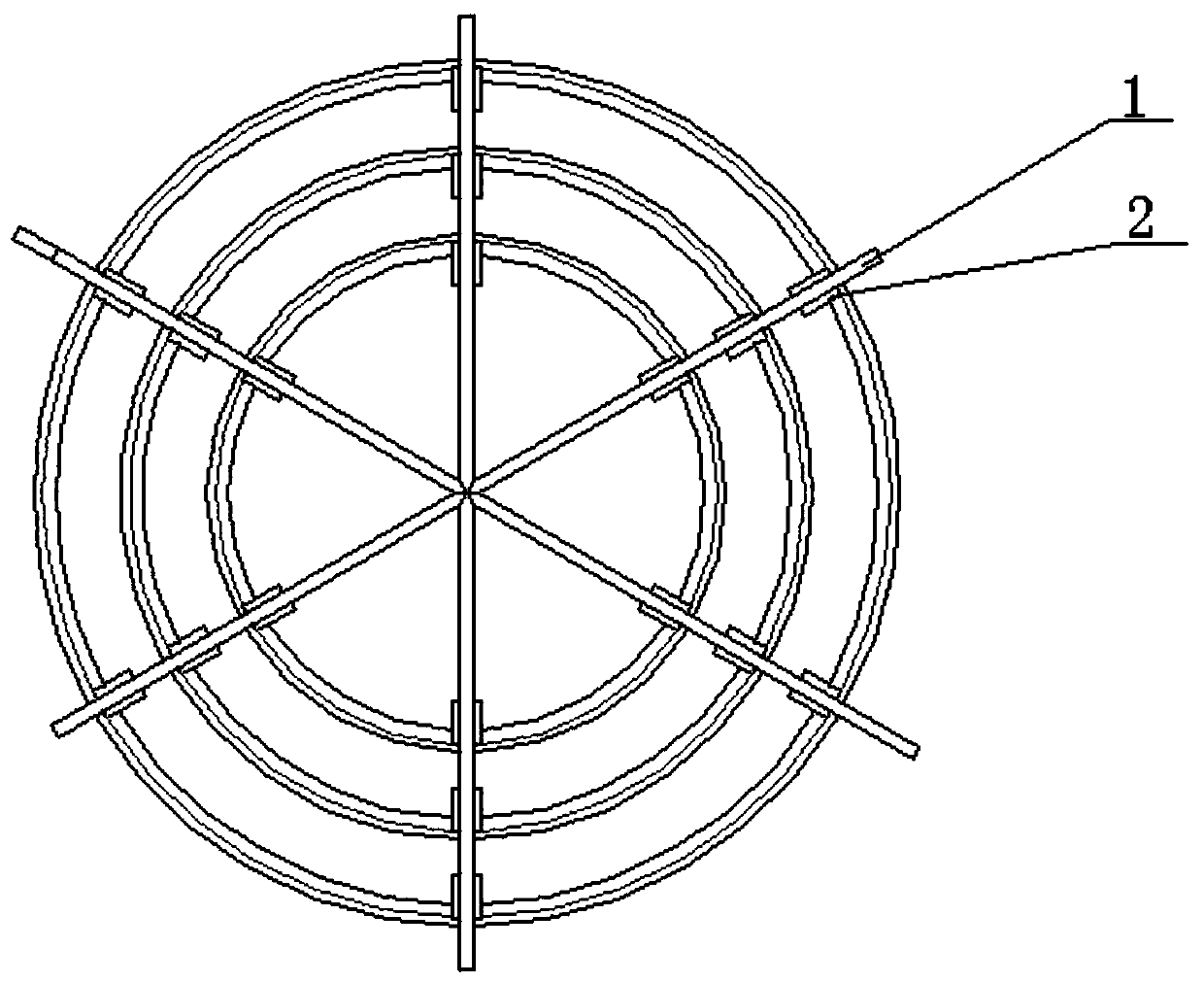

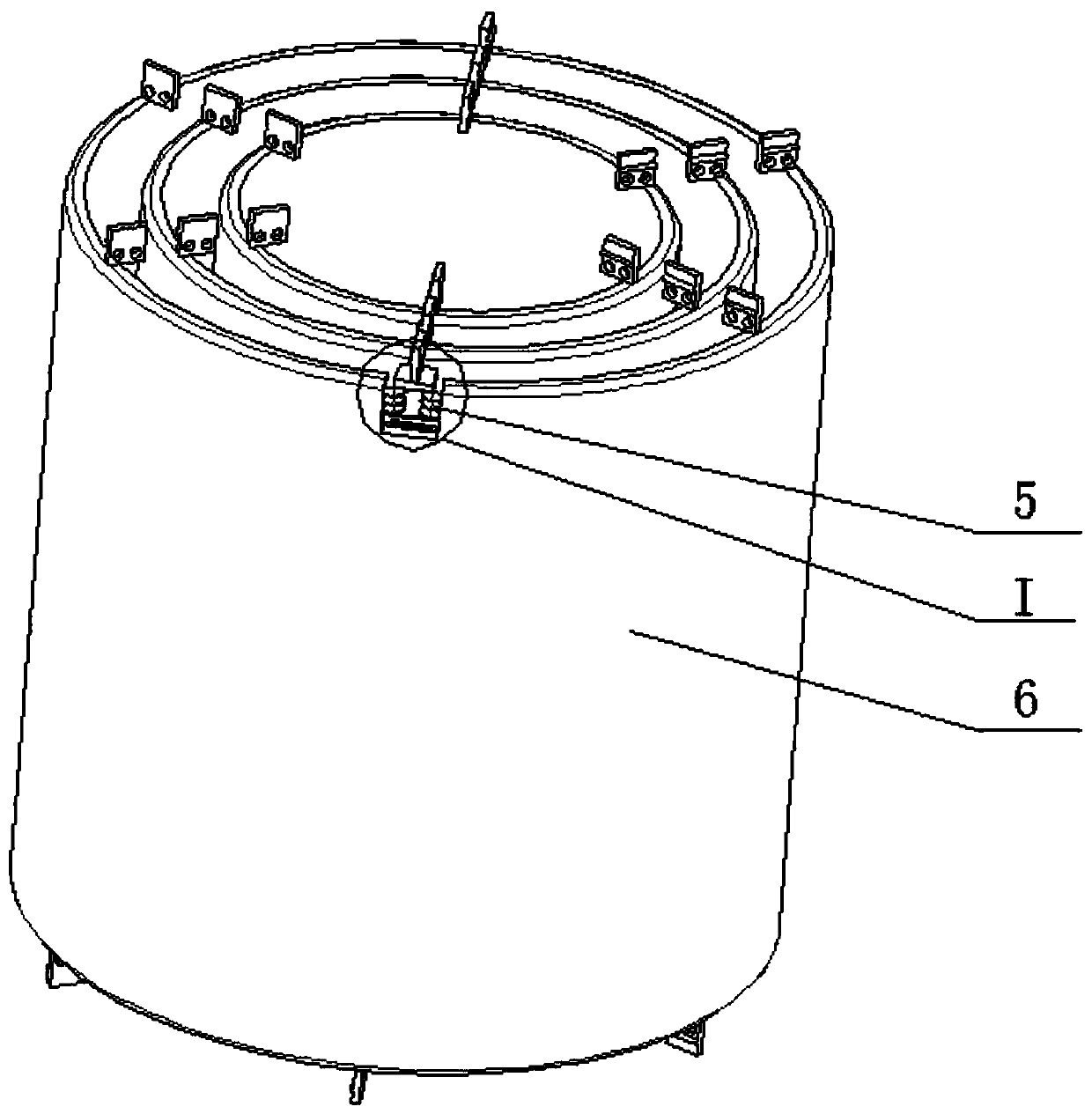

[0021] As shown in the figure, the dry-type air-core reactor with an interchangeable assembled structure includes a plurality of windings 3 (in this embodiment, three windings) using copper wires (or aluminum wires), a cast stainless steel transition clip 1, The transition clamp fixture 1 is divided into an exposed part and a pre-embedded part, the exposed part of the transition clamp clamp is provided with two clamp installation holes 101 laterally, and the embedded part of the transition clamp clamp is provided with wire connection holes from outside to inside 102 and a transverse circular groove 103. In this embodiment, the wire connection holes 102 are arranged in three rows and arranged up and down, and each row has two wire connection holes. Each wire 5 in the winding 3 passes through the wire connection hole 102 of the transition clamp 1 (passes through one wire connection hole in the same row, passes through another wire connection hole in the same row). The glass fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com