Immersion test device and test method for simulating corrosive pressure water environment

A test device, corrosive technology, applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, analysis by nuclear magnetic resonance, etc., to achieve the effect of reliable and stable pressure

Inactive Publication Date: 2019-12-03

HENAN INST OF ENG

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to study the interaction of water and rock in depth, it is necessary to fully consider factors such as water pressure and corrosiveness, and design a sample immersion device that can artificially simulate the corrosive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

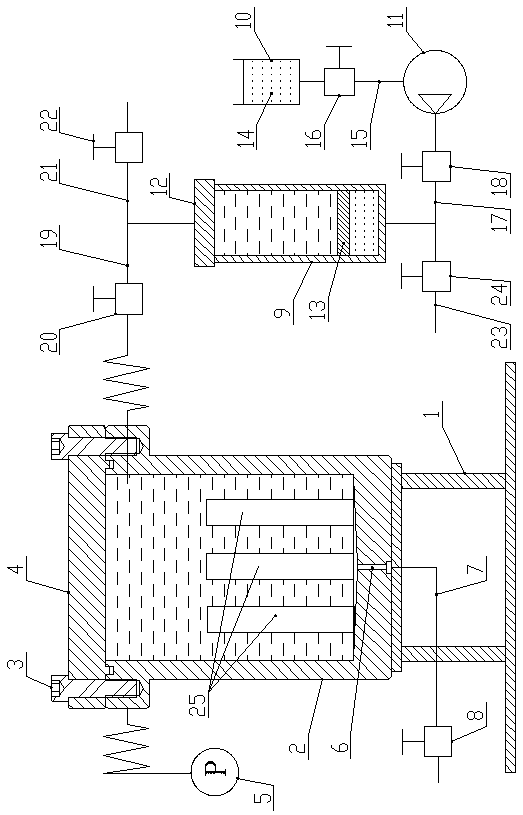

The invention provides an immersion test device and test method for simulating a corrosive pressure water environment. The device comprises a bracket, a pressure bearing barrel and a pressure device,a sealing cover is arranged at the top of the pressure bearing barrel through a detachable bolt, the bottom of the pressure bearing barrel is arranged on the bracket, a pressure gauge is connected toa side of the pressure bearing barrel, an upper and lower through liquid discharge hole is formed in a bottom center of the pressure bearing barrel, a liquid discharge pipe is connected to a lower port of the liquid discharge hole, a liquid discharge valve is arranged on the liquid discharge pipe, and the pressure device is connected with the side of the pressure bearing barrel. The immersion testdevice provided by the invention applies different hydrostatic pressures to acid and alkali corrosive water to perform immersion treatment on a rock sample so as to truly and effectively simulate thecorrosive pressure water environment, performs quantitative or qualitative research on the influence degrees and action mechanisms of water pressure, solution ion components, ion concentration, immersion time and the like on water-rock action according to the contrastive analysis of test results of the sample and the solution under different immersion working conditions, makes researches on basicproblems such as microscopic pores, mechanical properties and the like of rocks in the corrosive pressure water environment, and compensates the blanks and deficiencies on the researches of the water-rock action.

Description

technical field [0001] The invention belongs to the technical field of engineering geology and geotechnical engineering, and in particular relates to a immersion test device and method for simulating a corrosive pressure water environment. Background technique [0002] Groundwater is the most active factor in the geological environment. After the rock mass encounters water, the continuous physical, chemical and mechanical effects of groundwater on the rock mass, as well as the influence of water on the state of the medium, are called water-rock interactions. Water-rock interaction widely exists in the surface rock and soil and deep in the earth's crust. Under the influence of water-rock interaction, the strength and mechanical behavior of rock mass will change, which will lead to various engineering disasters. [0003] Water-rock interaction includes physical action, chemical action and mechanical action. The physical action mainly includes the processes of lubrication, so...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N17/00G01N21/73G01N24/08G01N23/2251G01N23/207G01N15/08

CPCG01N15/088G01N17/00G01N21/73G01N23/207G01N23/2251G01N24/081

Inventor 郭兵兵常利营赵新涛陈国祥

Owner HENAN INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com