Mining roller cage shoe strain pressure test bench

A technology of roller can ears and pressure test, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve problems such as large quality differences, potential safety hazards, and differences in service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

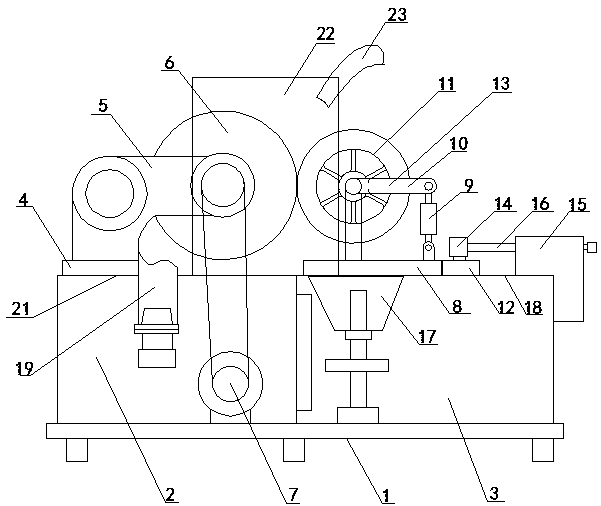

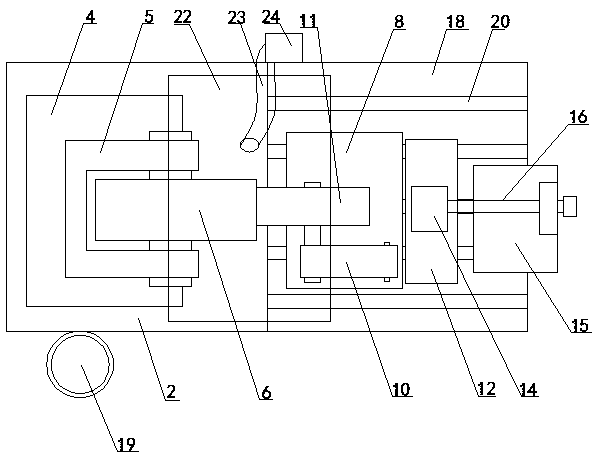

[0012] according to Figures 1 to 2 As shown, the present invention relates to a mine roller can lug fatigue pressure test bench, which includes a foundation base plate 1, a first box body 2 with a first workbench 21 is fixed on the left side of the upper part of the base base plate 1, and the The front side outer wall of the first box body 2 is provided with a spreader mounting seat 19 on which a spreader is installed. The upper surface of the first workbench 21 of the box body is fixed with a fixed seat 4, and An inverted L-shaped extension arm 5 is integrally provided, and the inverted L-shaped free end of the extension arm 5 is provided with a runner 6 with a counter. Motor 7, described motor 7 drives described runner 6 to rotate by belt, and the upper right side of described foundation bottom plate 1 is provided with the second box body 3 that band second workbench 18 and can be lifted by lifting device 17, so The upper surface of the second box body 3 and the second wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com