Connecting structure and terminal

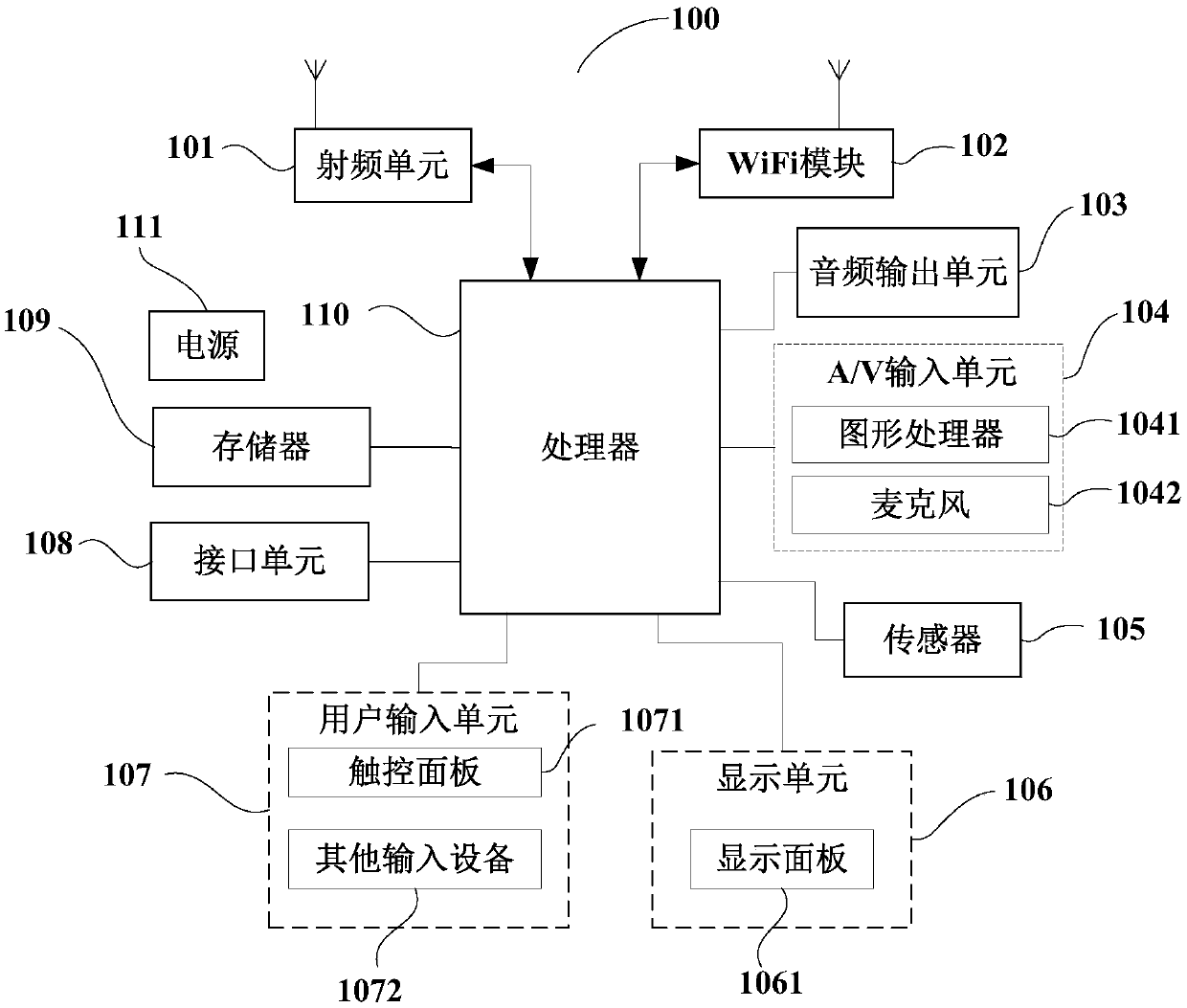

A connection structure and terminal technology, applied in bracelets, watch straps, clothing, etc., can solve the problems of cumbersome wearing methods and inability to automatically shape wearable devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

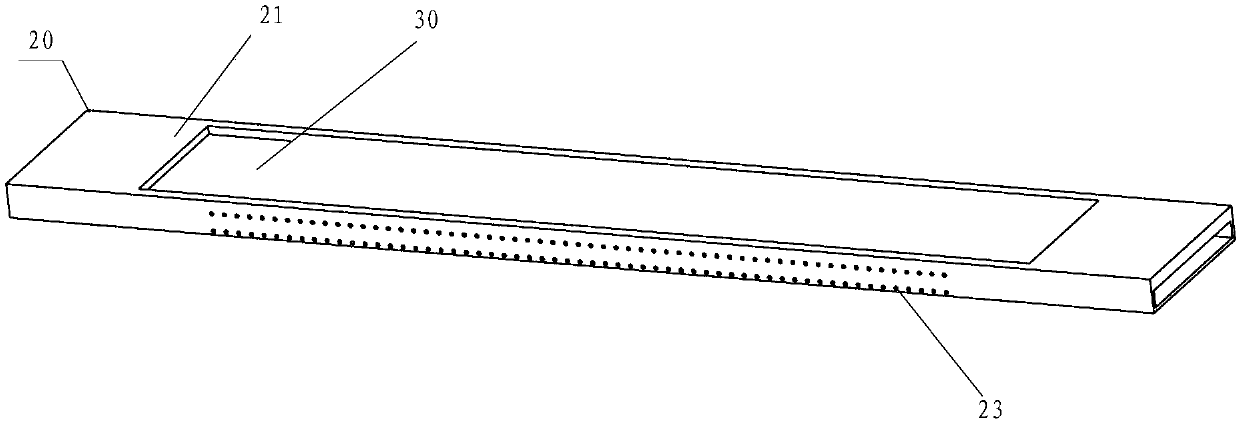

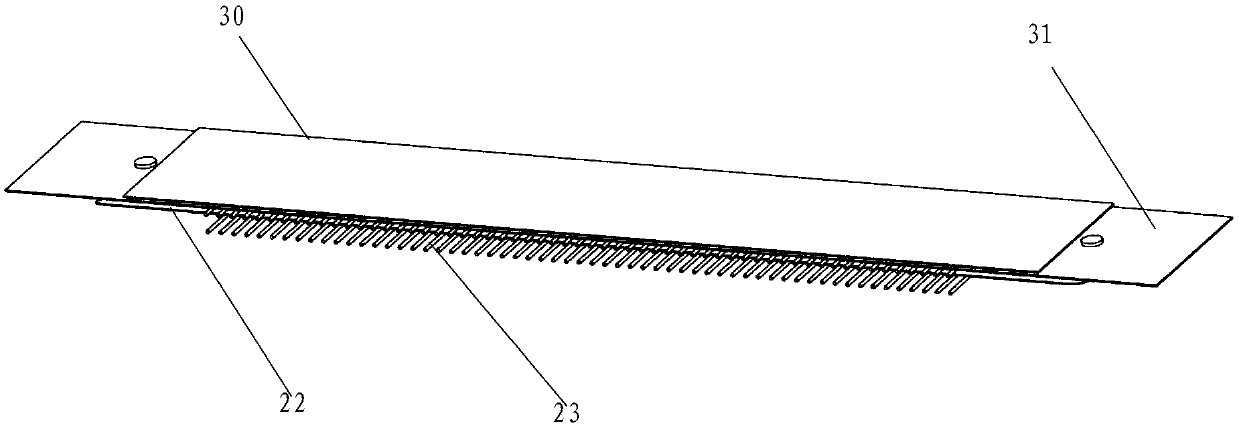

[0041] Please refer to figure 2 , 3 , figure 2 A schematic diagram of the overall structure of the terminal provided in this embodiment, image 3 It is a schematic structural diagram of the terminal provided in this embodiment after removing the flexible shell; the terminal includes a flexible screen module 30 and a connecting structure 20, which is used for wearing and connecting the terminal; the connecting structure 20 includes a flexible shell 21 and a power steel sheet 22. The power steel sheet 22 is arranged in the flexible casing 21, and at least one end of the power steel sheet 22 in the length direction is movably connected with the flexible casing 21; A smooth guiding layer 23 is provided on the surface of at least one inner side wall.

[0042] The power steel sheet 22 involved in this embodiment is a thin steel sheet with elasticity, also known as the snap ring steel sheet, which has two states, namely a straight state and a curled state. , the power steel she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com