Welding machine wire changing control method and device, welding machine and computer readable storage medium

A control method and computer technology, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems that workers spend a lot of time and affect the normal production of the workshop, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

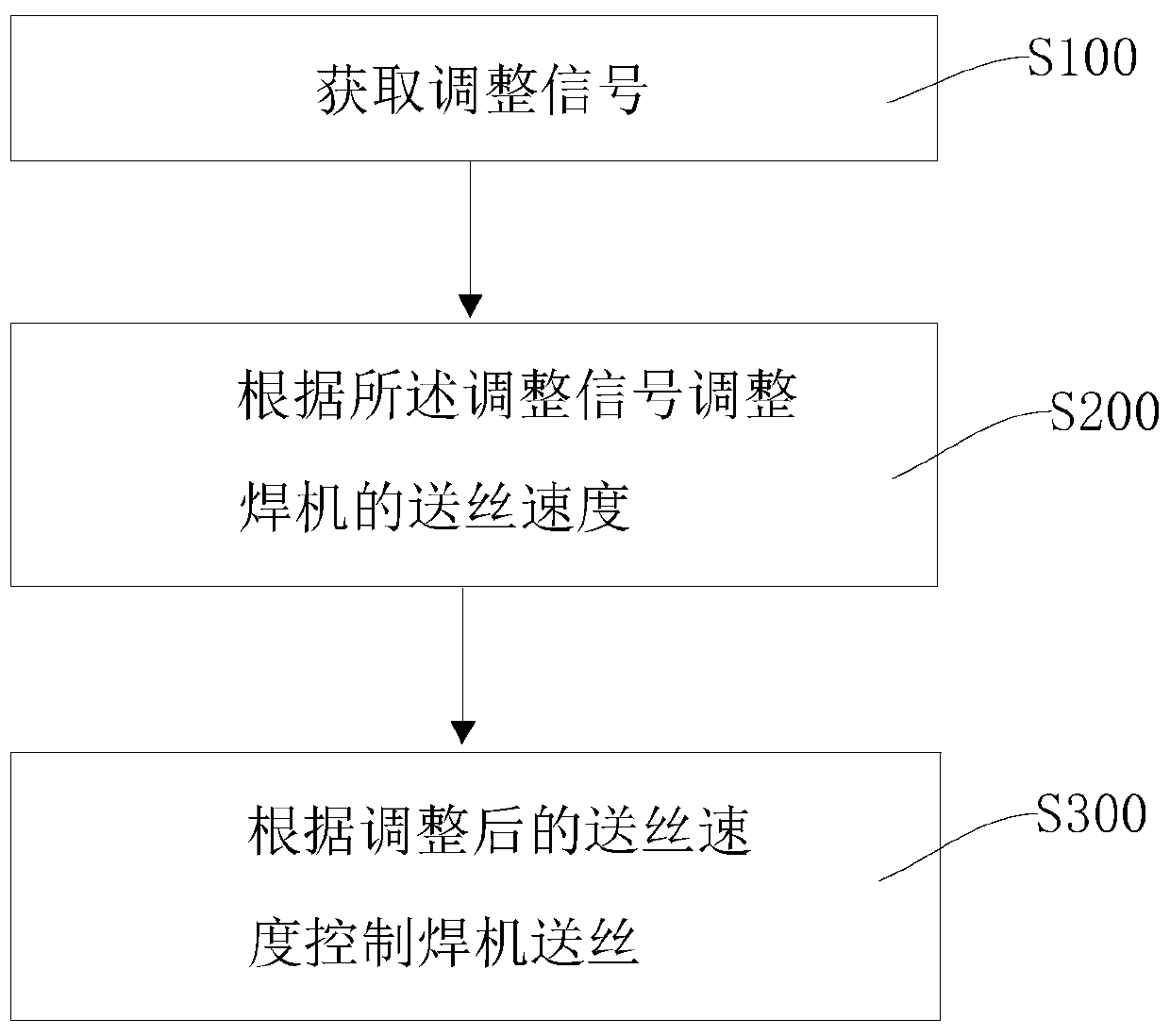

[0024] figure 1 It is a schematic flow chart of a control method for changing wires of a welding machine according to an embodiment of the present invention, as figure 1 As shown, a control method for welding wire replacement, including:

[0025] Step S100: During the wire changing process, an adjustment signal is obtained, and the adjustment signal includes a first signal, or a first signal and a second signal.

[0026] Step S200: Adjust the wire feeding speed of the welding machine according to the first signal or the second signal.

[0027] Step S300: Control the wire feeding of the welding machine according to the adjusted wire feeding speed.

[0028] The control method for changing the wire of the welding machine of the present invention obtains the adjustment signal before changing the welding wire, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com