Yarn feeding flexible clamping device for textile machine

A textile machine and thread feeding technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, can solve the problems of burrs, failure to consider the mutual contact between yarns and fixtures, and damage to the fiber structure of yarns. Achieve the effect of reducing the possibility of burrs, facilitating real-time monitoring, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

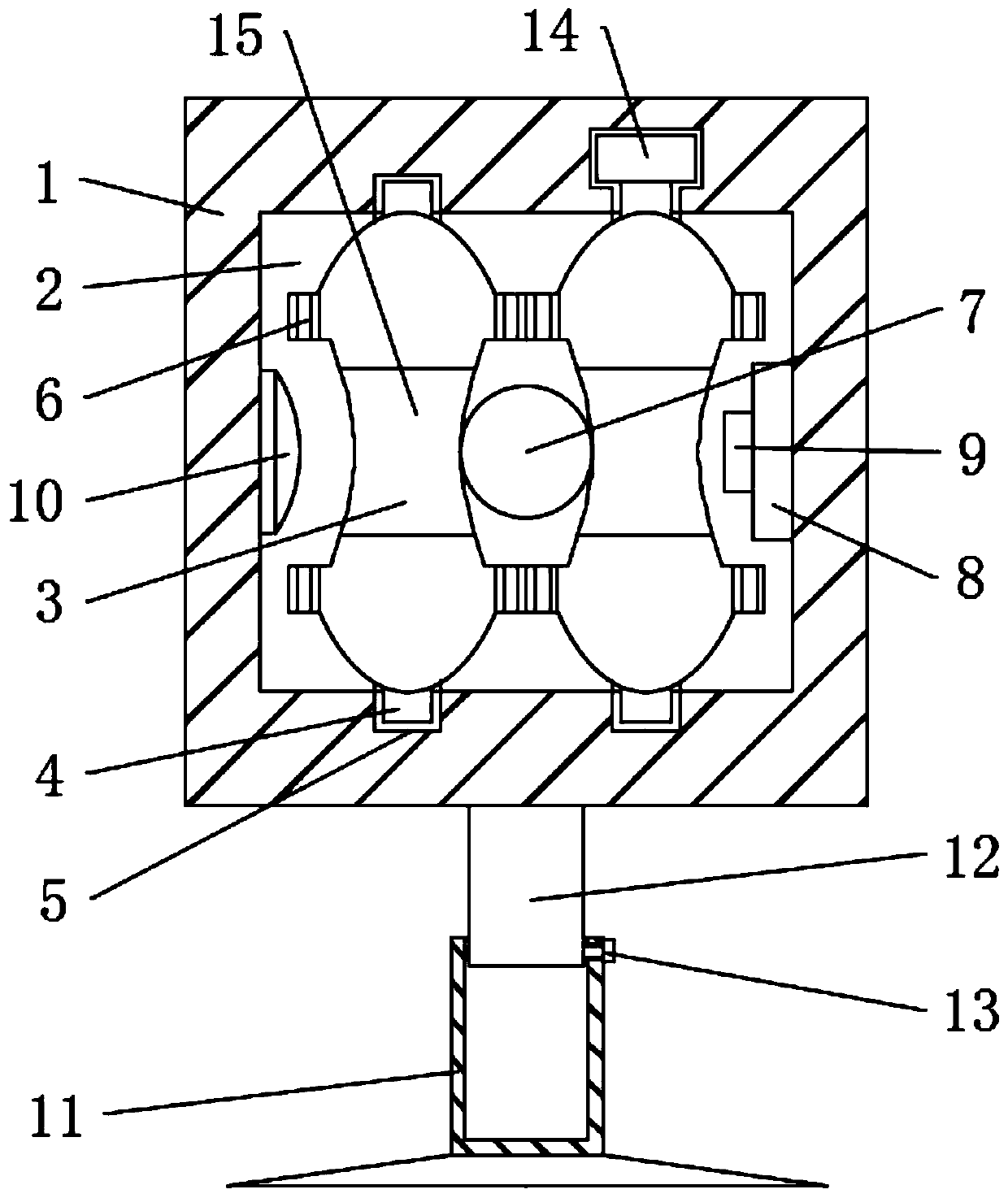

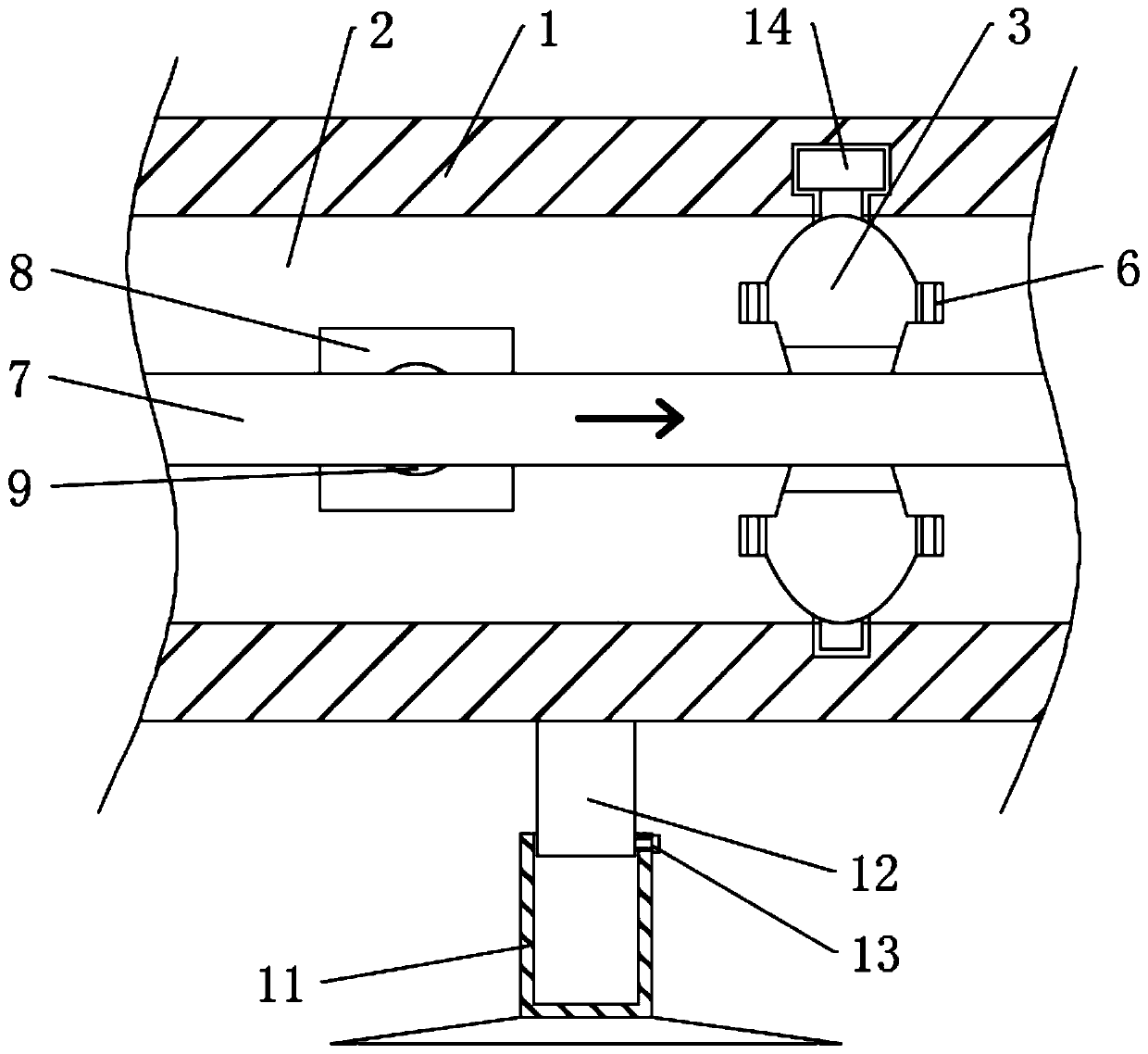

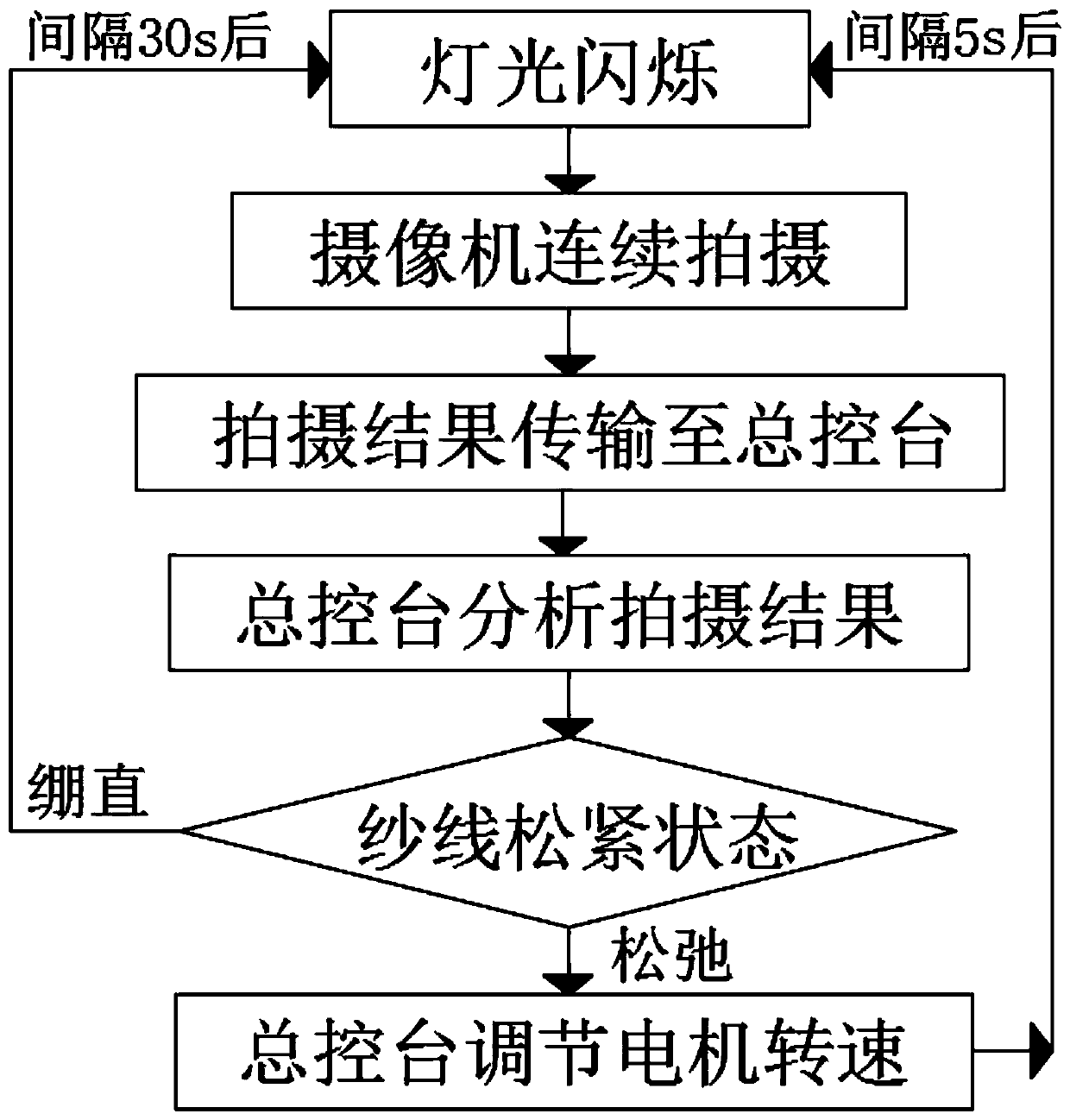

[0043] A soft clamping device for incoming wires of textile machines, please refer to figure 1 , including the fixture body 1, a through hole 2 is drilled in the fixture body 1, two grooves 5 are dug at the upper and lower ends of the through hole 2, positioning rollers 3 are arranged at the left and right ends of the through hole 2, and the upper and lower ends of the positioning roller 3 Both are fixedly connected to the limit shaft 4, the limit shaft 4 rotates in the groove 5, the upper end of the right limit shaft 4 is fixedly connected to the motor 14, the motor model is: yyhs-20 type, and the upper and lower ends of the two positioning rollers 3 are fixed A gear 6 is connected, and two adjacent gears 6 on the left and right are matched with each other, and a yarn 7 is arranged between the two positioning rollers 3, and the yarn 7 and the two positioning rollers 3 are in contact with each other. When the rotation speeds of the two yarns 7 are exactly the same, the frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com