Industrial robot force/position compliance control method based on kinetic parameter identification

A dynamic parameter, industrial robot technology, applied in the field of control, can solve the problems of difficult to verify the controller, lack of practical experiments, etc., to achieve the effect of physical feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

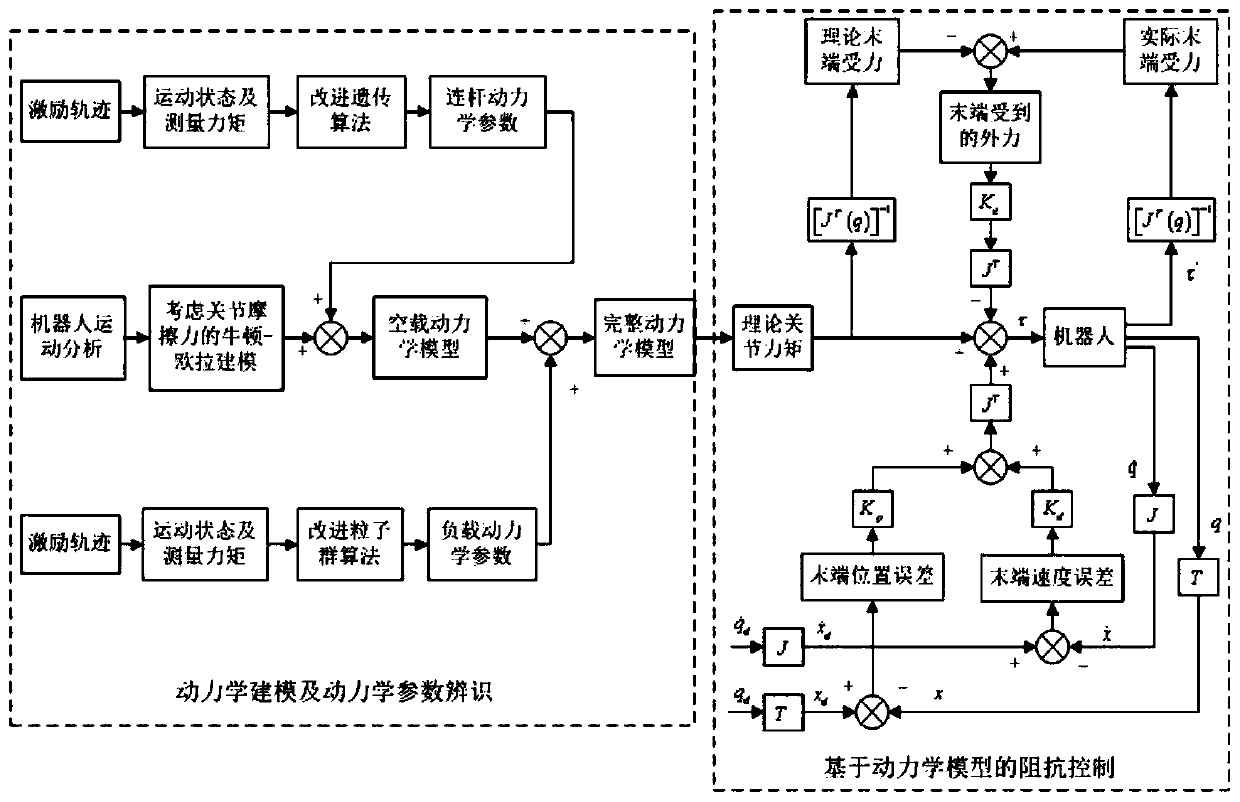

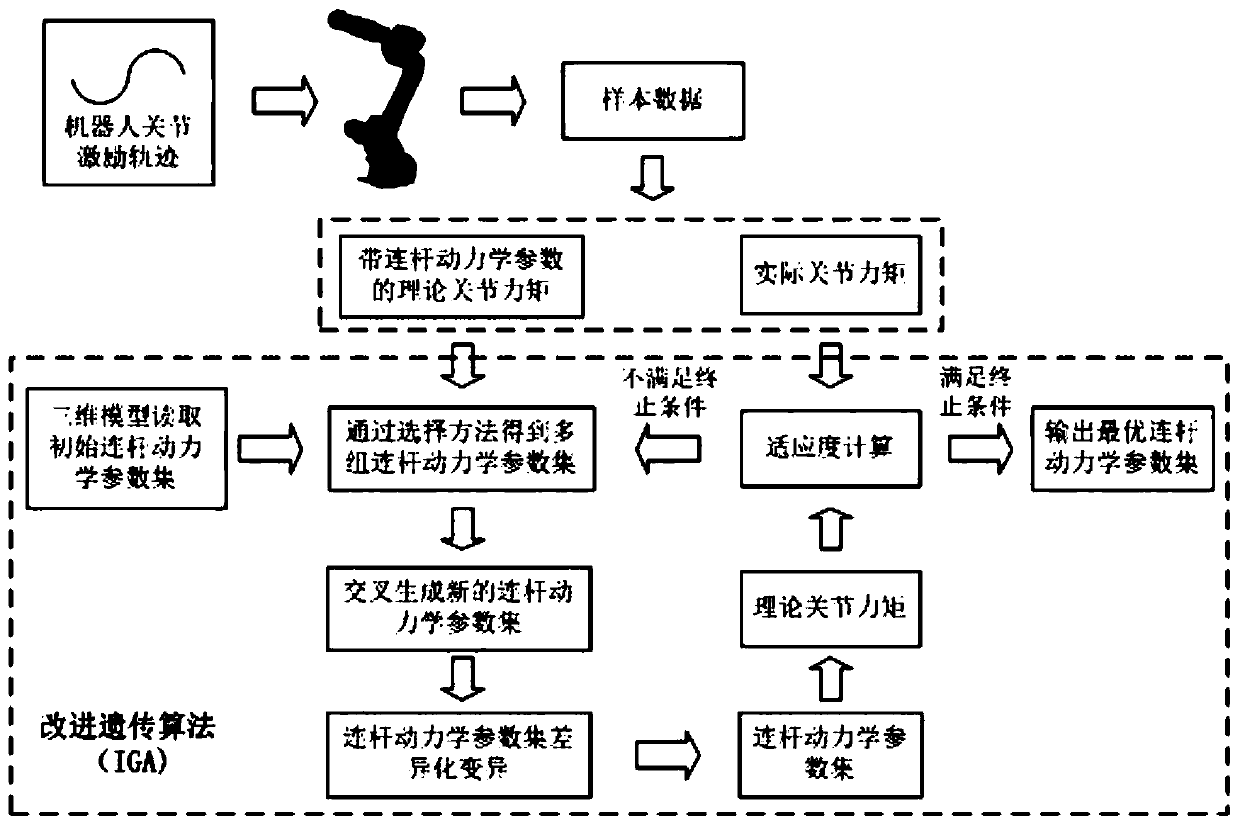

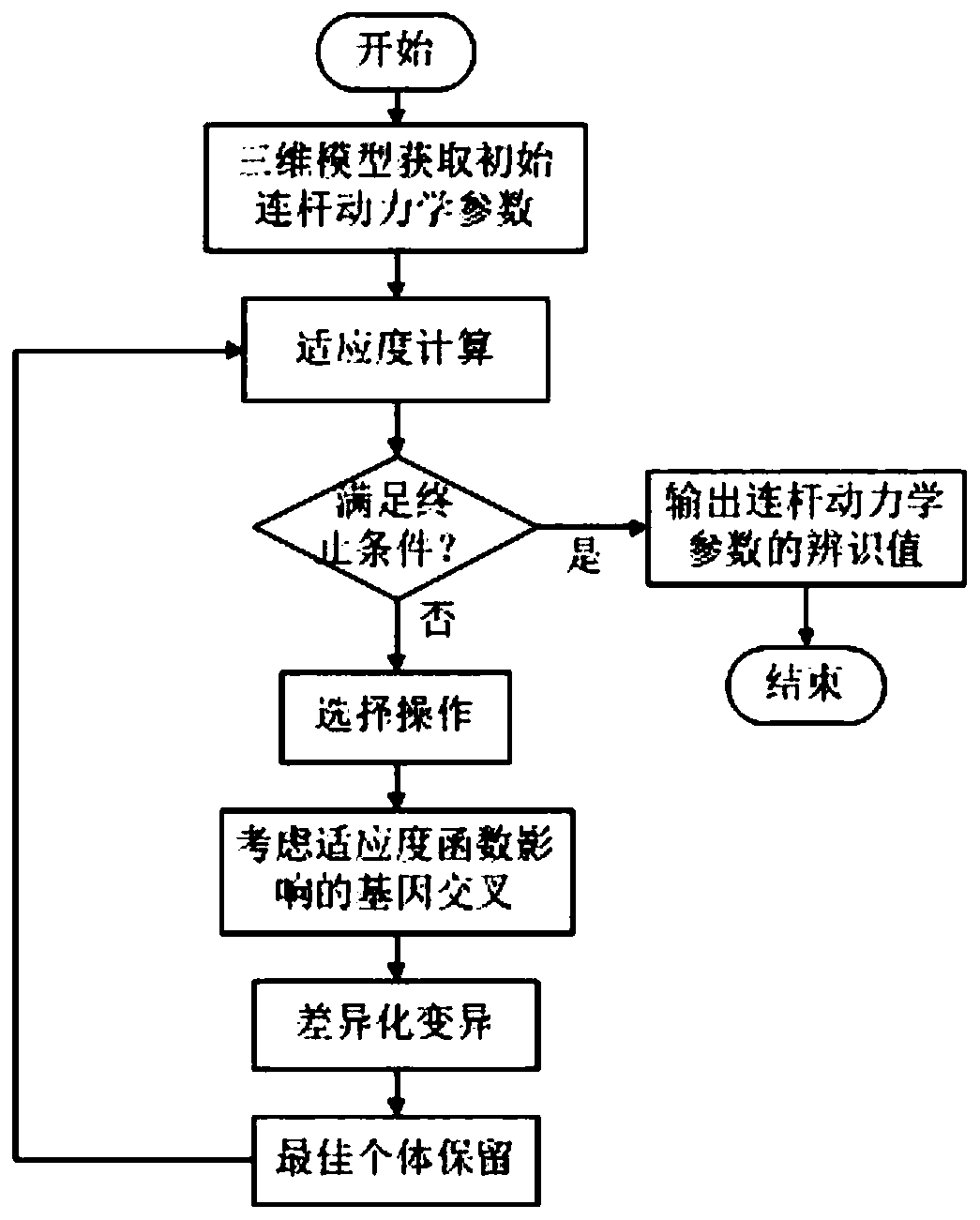

Method used

Image

Examples

Embodiment

[0128] The present invention verifies the practicability of the proposed dynamic parameter identification algorithm and force / position compliance control algorithm through experiments, introduces the experimental platform of six-link industrial robot and designs the experimental schemes respectively, and verifies the proposed improved genetic algorithm through experiments And improve the practicability and reliability of the particle swarm algorithm identification, thus constructing an accurate and complete dynamic model, and on this basis, the compliance effect of the impedance controller based on the dynamic model on the end force and position is confirmed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com