A method for preventing honeycomb core solidification instability deformation and slippage

A technology of unstable deformation and honeycomb core, which is applied in the field of preventing the unstable deformation and slippage of the honeycomb core during curing. It can solve the problems of deformation, shrinkage and instability of the honeycomb sandwich core, achieve simple and effective process methods, and improve the quality of bonding and co-curing , the effect of preventing instability and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

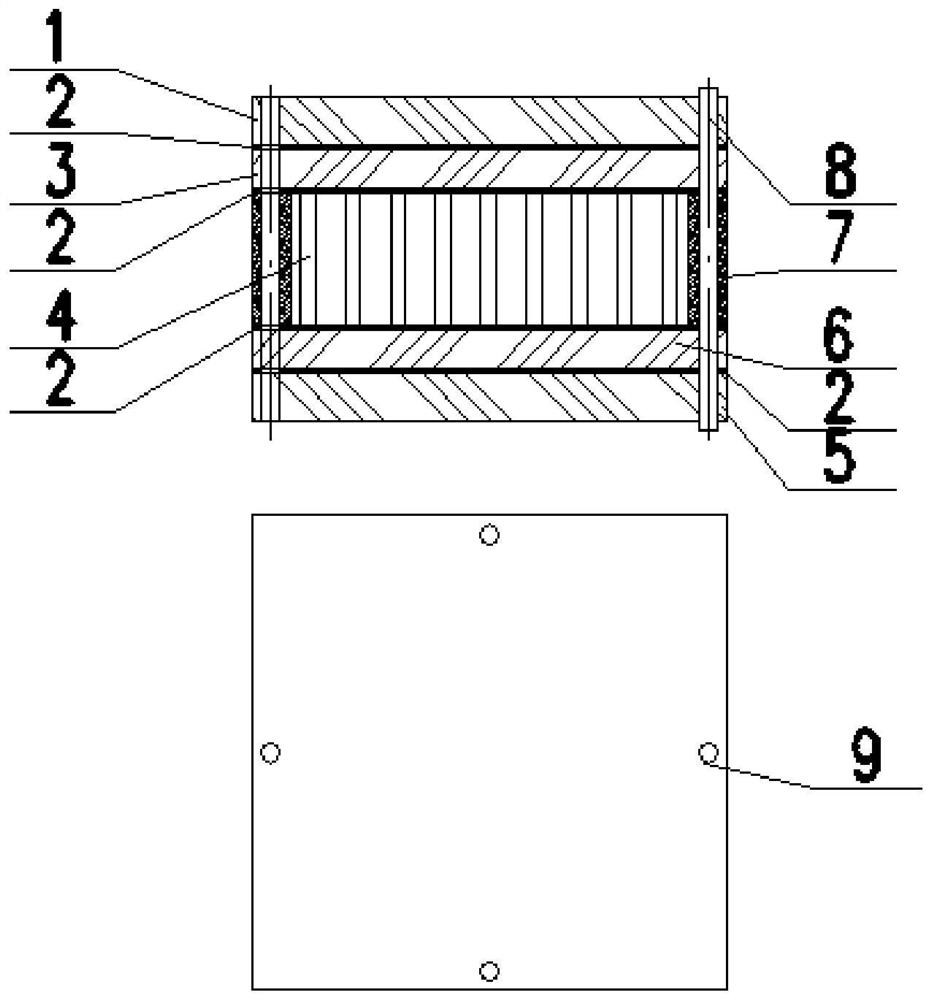

[0012] Composite parts with honeycomb sandwich structure. The parts are composed of upper and lower gaskets, upper panels, Nomex honeycomb cores, adhesive films, and lower panels. Among them, the gasket is a cured composite material laminate, which is glued and co-cured with the upper and lower panels, honeycomb core and adhesive film. Reserve 50mm margins around each component of the honeycomb core and other components, use the potting compound to pot the 30mm margin area on the edge of the honeycomb core, and cure at room temperature. The gaskets are combined, the edges are aligned and fixed with tape, and positioning holes are drilled in the margin area 30mm wide from the edge of each edge of the gasket and honeycomb core, and positioning pins matching the thickness of the parts are made. Lay the adhesive film and the upper and lower panel prepregs on both sides of the honeycomb core where the positioning holes are drilled. Lay the adhesive film on the glued surface respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com