A kind of positive and negative battery cell direction screening transmission method

A transmission method and technology of positive and negative electrodes, which are used in conveyor objects, transportation and packaging, and electrolyte battery manufacturing, etc., can solve the problems of difficulty in the direction of positive and negative electrodes of cells, facilitate the arrangement of cells, and achieve a high degree of automation. Production and avoid the effect of manually arranging cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

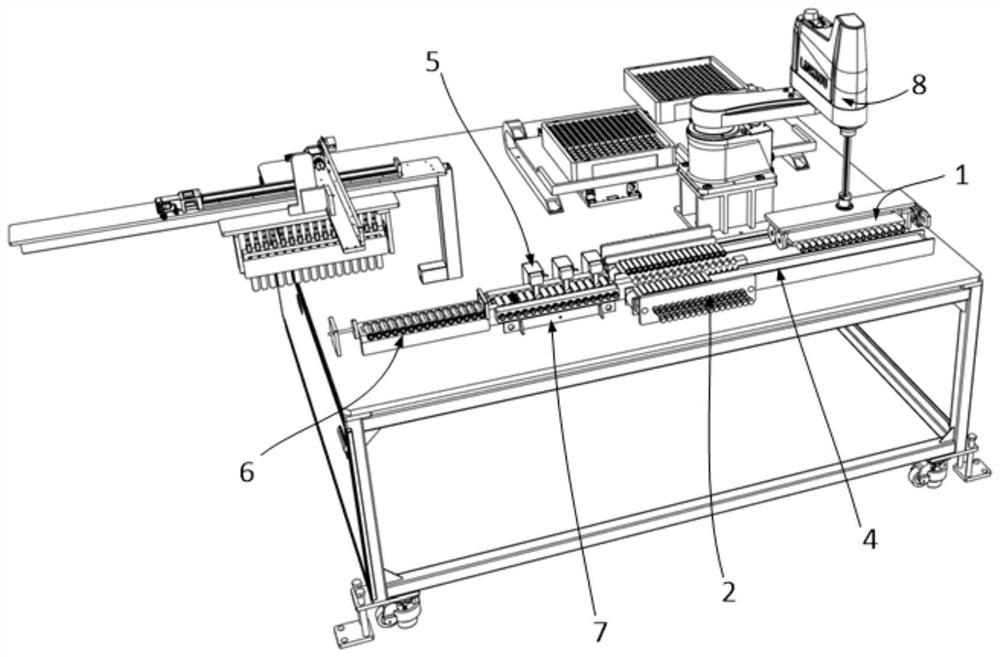

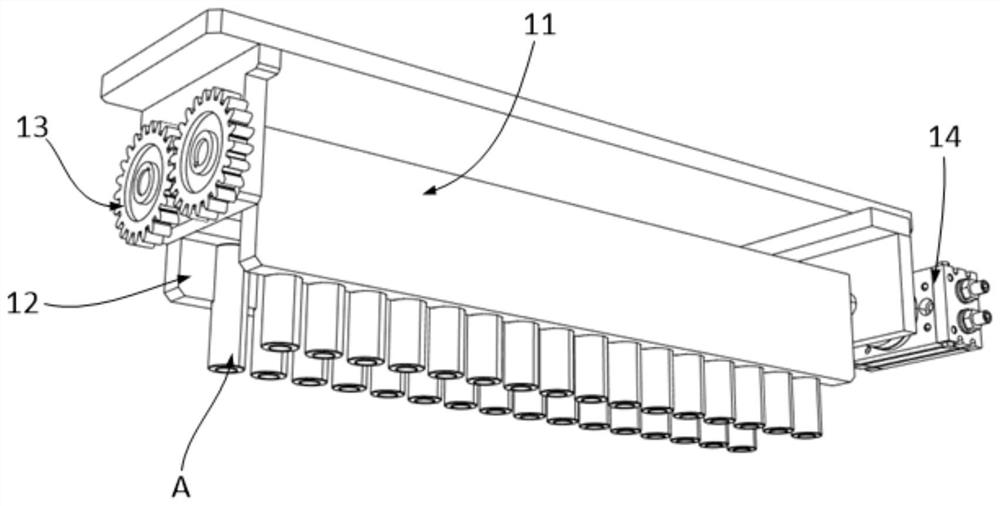

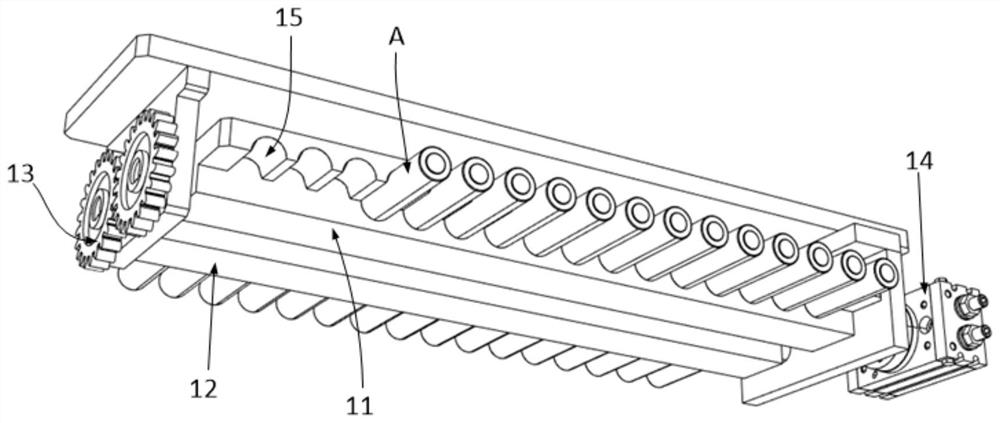

[0066] This embodiment provides a positive and negative cell orientation device, such as Figure 1-4 shown, including:

[0067] Steering socket 1, said steering socket 1 comprises a first steering socket 11 and a second steering socket 12, said first steering socket 11 and second steering socket 12 have rows of fixed or releasable The slot 15 of the electric core; the first steering row 11 and the second steering row 12 are arranged side by side in parallel, and driven by the driver 14, the first steering row 11 and the second steering row 12 can Rotate in the opposite direction so that the slots 15 of the two face oppositely;

[0068] The conveyor belt 4 is used to transfer and gather the batteries released by the steering plug-in strip 1, including a first conveyor belt 41 and a second conveyor belt 42, and the first conveyor belt 41 and the second conveyor belt 42 are respectively located on two sides side by side, for respectively Receiving the batteries released by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com