Fiber-reinforced resin composition and method of producing same

A fiber-reinforced resin and composition technology, applied in the field of fiber-reinforced resin composition and its manufacture, capable of solving problems such as cracking, brittle fracture, and brittle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

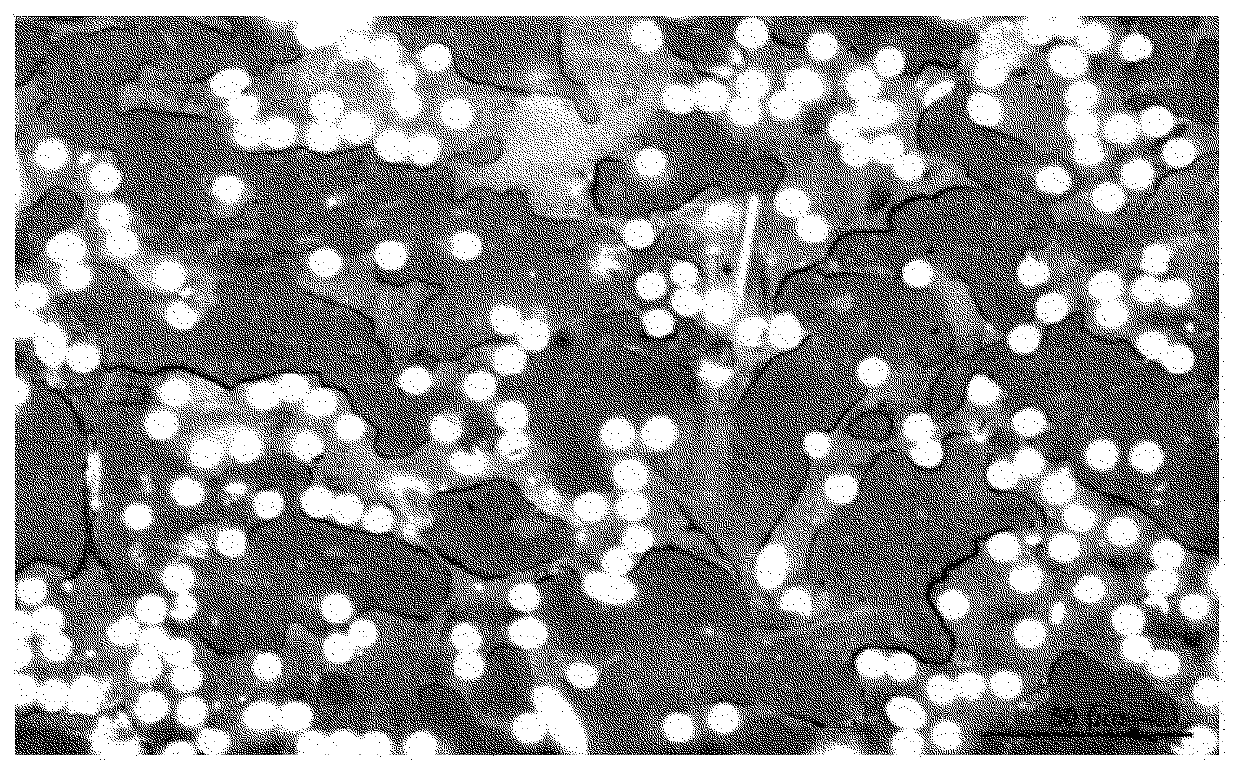

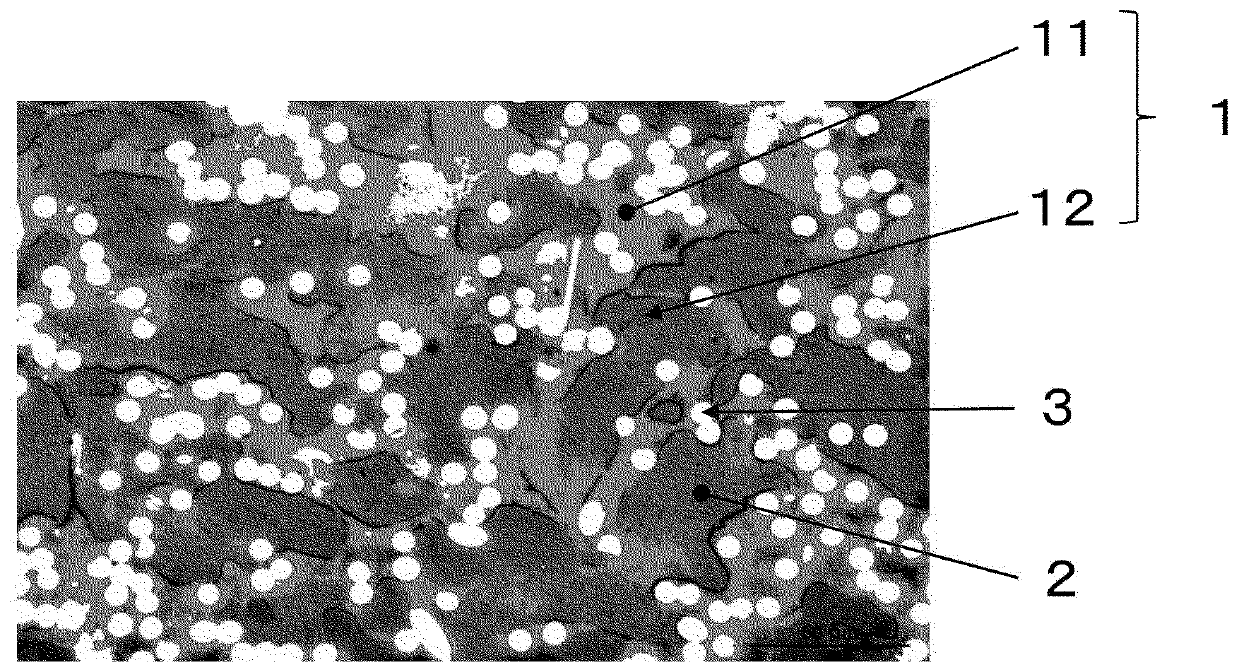

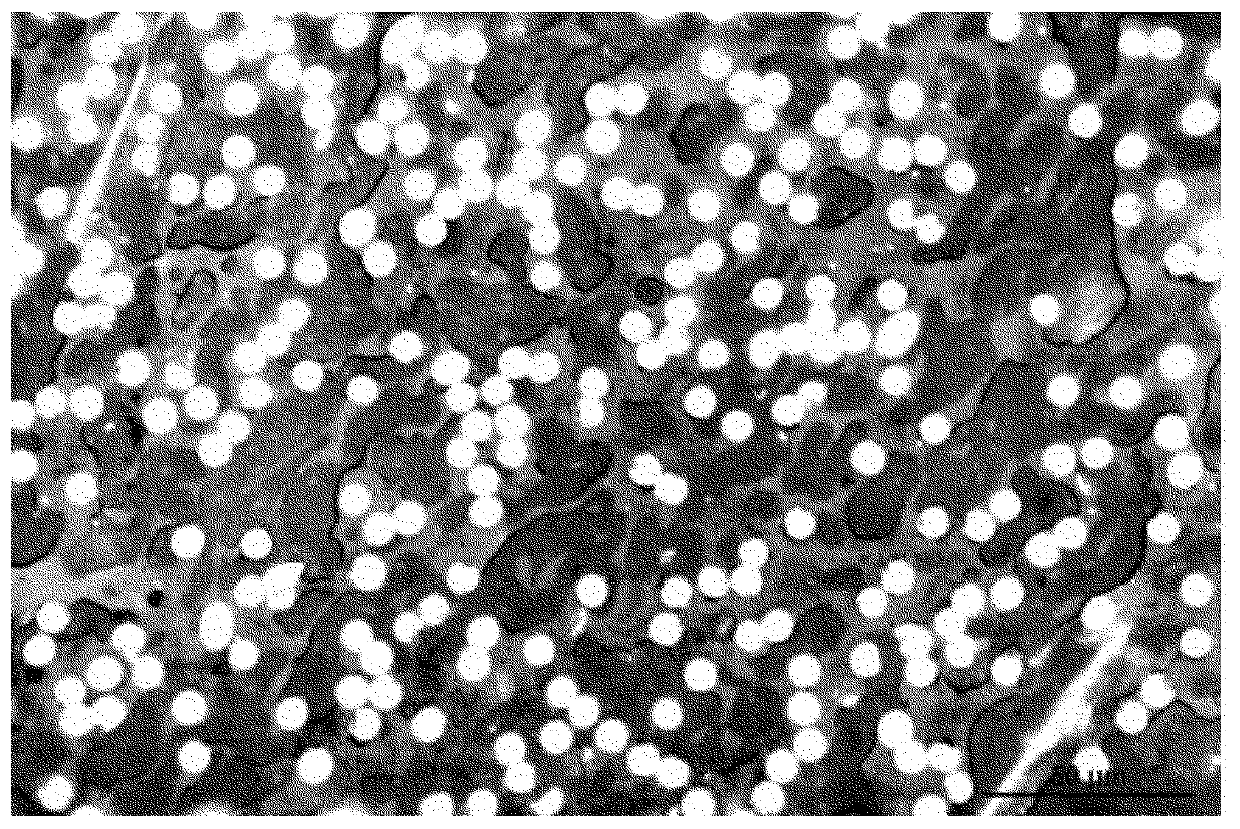

Image

Examples

Embodiment 1

[0108] First, pellets of carbon fiber-reinforced polyamide (PA-CF, "Plastron PA6-CF40", manufactured by Daicel Polymer Co., Ltd.) in which polyamide 6 (PA) and carbon fiber (CF) were pre-mixed at a mass ratio of 3:2 50 parts by mass and 50 parts by mass of polypropylene (PP, "E111G", manufactured by Prime Polymer Co., Ltd., MFR: 0.5 g / 10min) were dry-blended, and then molded in a cylinder using a bench-top injection molding machine (manufactured by Shinko Cellbic Co., Ltd.). Temperature: Melting and kneading at 270° C. to obtain a resin composition, and injection molding at a mold temperature of 135° C. to prepare a sample piece for physical property measurement obtained by molding the resin composition in a JIS K71621BA mold.

Embodiment 2

[0110] In addition to 45 parts by mass of carbon fiber-reinforced polyamide pellets (PA-CF), 47 parts by mass of polypropylene (PP), 3 parts by mass of polyamide 6 (PA, "A1030BRL", manufactured by Unichika Co., Ltd.), polypropylene ( PP, MFR: 0.5g / 10min) and carbon fiber reinforced polypropylene pellets (PP-CF, "Plastron PP-CF40", manufactured by Daicel Polymer Co., Ltd.) 5 mass A sample piece for physical property measurement was produced in the same manner as in Example 1 except that each part was used after dry blending.

Embodiment 3

[0112] In addition to carbon fiber reinforced polyamide pellets (PA-CF) 40 mass parts, polypropylene (PP) 44 mass parts, polyamide 6 (PA) 6 mass parts and carbon fiber reinforced polypropylene pellets (PP-CF) 10 Sample pieces for physical property measurement were produced in the same manner as in Example 1, except that parts by mass were used after dry blending.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com