The formwork used for forming the reverse sill at the bottom of the indoor waterproof and moisture-proof filled wall

A technology for filling walls and formwork, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, on-site preparation of building components, etc. problem, to achieve the effect of convenient cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

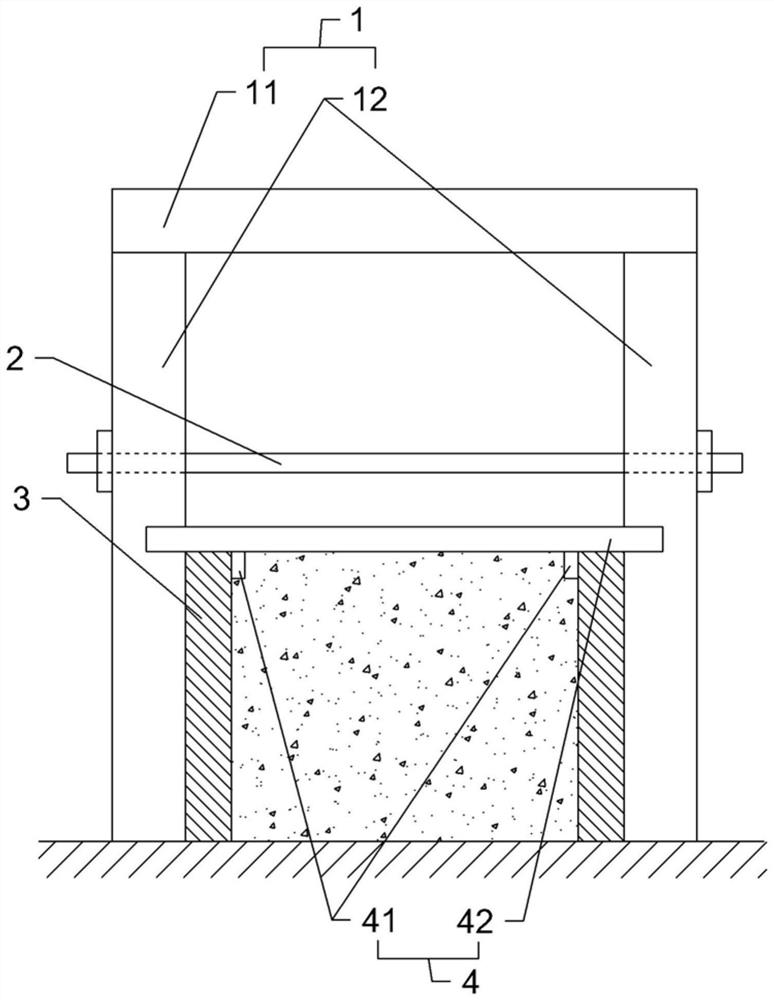

[0022] Embodiment one: as attached figure 1 Shown: the formwork used for forming the reverse sill at the bottom of the indoor waterproof and moisture-proof filling wall, including formwork groups and supporting mechanisms, the formwork group 3 includes two parallel formworks 3, and the forming for pouring the reverse sill is formed between the two formworks 3 space. The support mechanism includes an outer fixture 1 and an inner support 4, the outer fixture 1 includes two vertically arranged support rods 12 and a connecting rod 11, the connecting rod 11 is located between the two supporting rods 12 and is connected to the two supporting rods. The rods 12 are rigidly connected, and two support rods 12 and one connecting rod 11 form a door-shaped structure; a horizontal locking adjustment part is arranged between the two support rods 12, and the locking adjustment part is located below the connecting rod 11, and the locking The adjusting member is preferably a pull bolt 2 , and ...

Embodiment 2

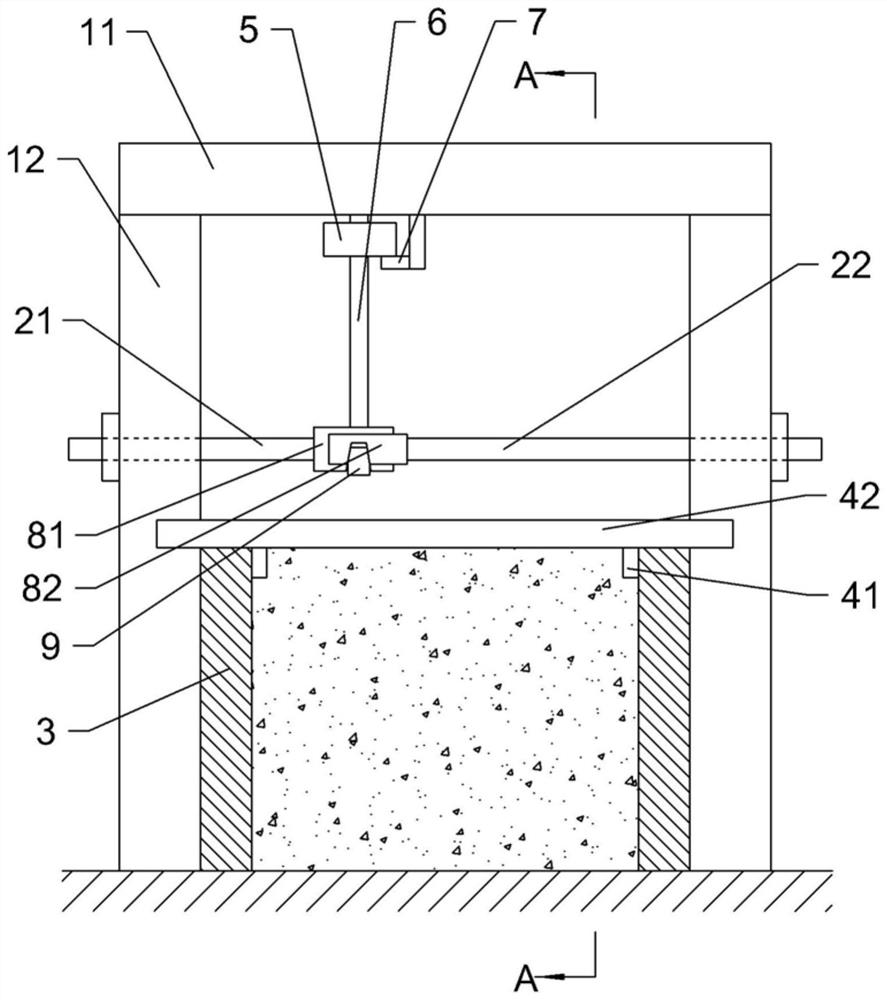

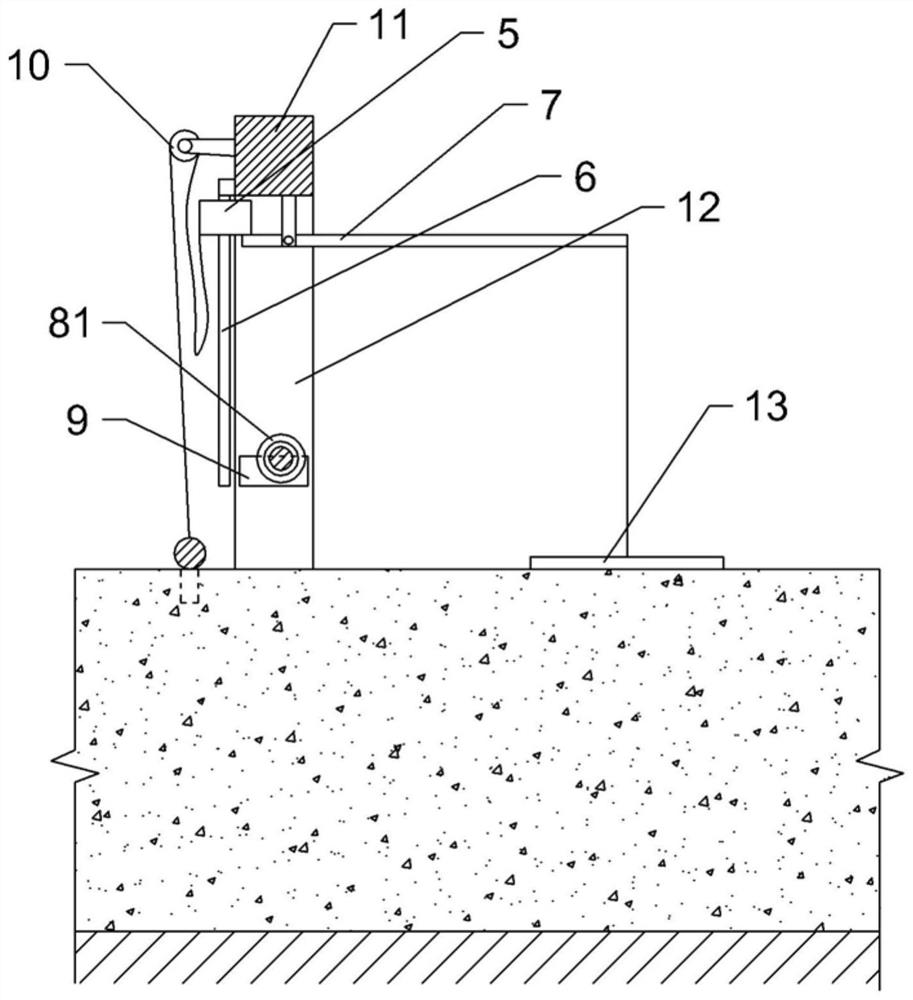

[0024] Embodiment two: the difference with embodiment one is only: as figure 2 and image 3 As shown, the pull bolt 2 includes a first screw 21 and a second screw 22, the first screw 21 and the second screw 22 are coaxially separated, and the end of the first screw 21 facing the second screw 22 is coaxially welded with a sleeve 81, the side wall of the sleeve 81 is provided with a first bayonet that runs through the side wall of the sleeve 81, and the end of the second screw 22 facing the first screw 21 is welded with a slider 82, the slider 82 is inserted into the sleeve 81 and Slidingly fit with the sleeve 81 along the axis of the sleeve 81, the slider 82 is provided with a second bayonet opposite to the first bayonet; The block 9 in the bayonet; the top of the casing 81 is provided with a vertical guide rod 6, and the upper end of the guide rod 6 is threadedly connected with the connecting rod 11; 5 is greater than the weight of the inner support 4; the connecting rod 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com