Cleaning mechanism for outer surface of garbage can

A technology for cleaning mechanism and outer surface, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as unsatisfactory, wet human body, troublesome washing, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

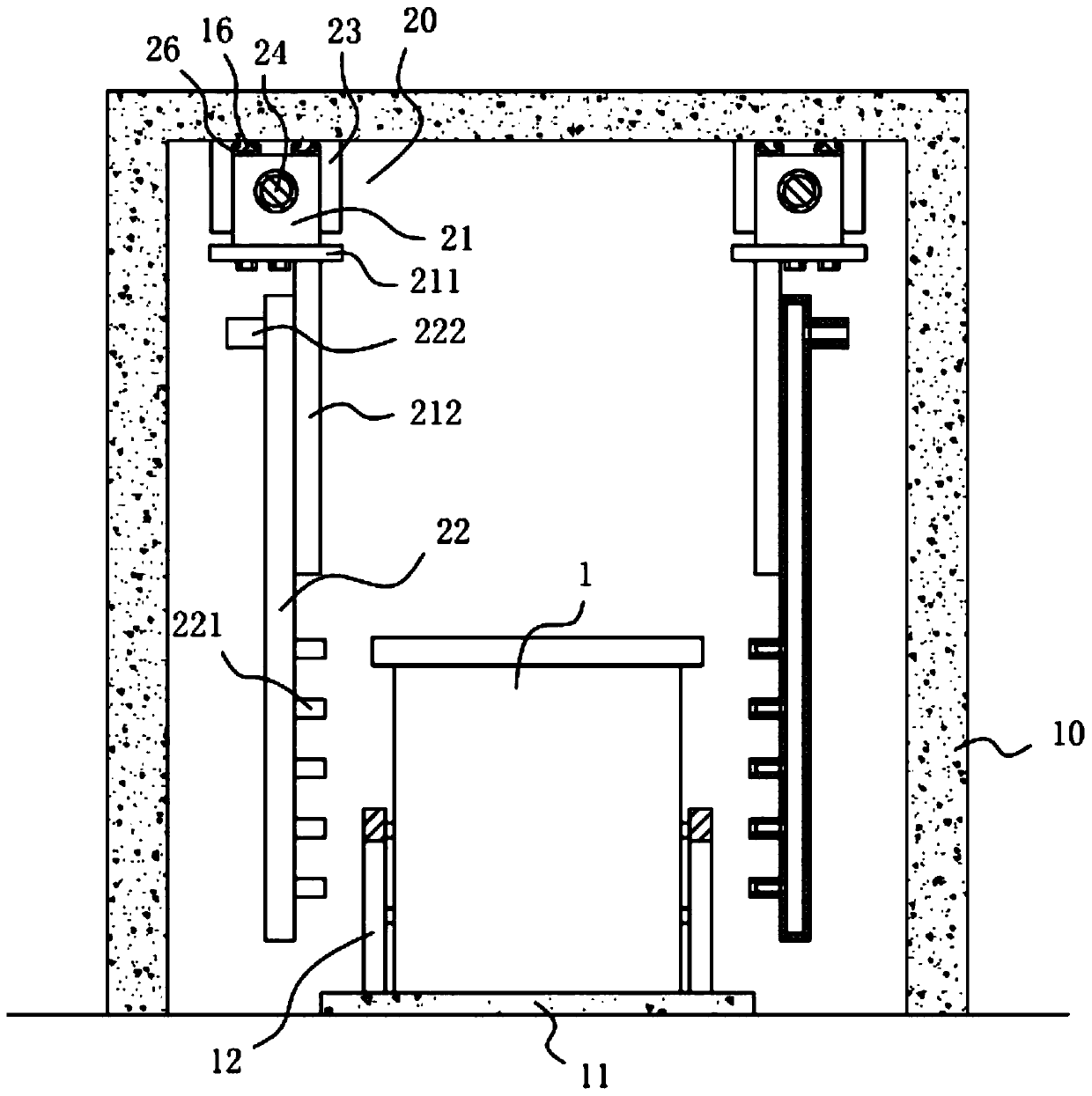

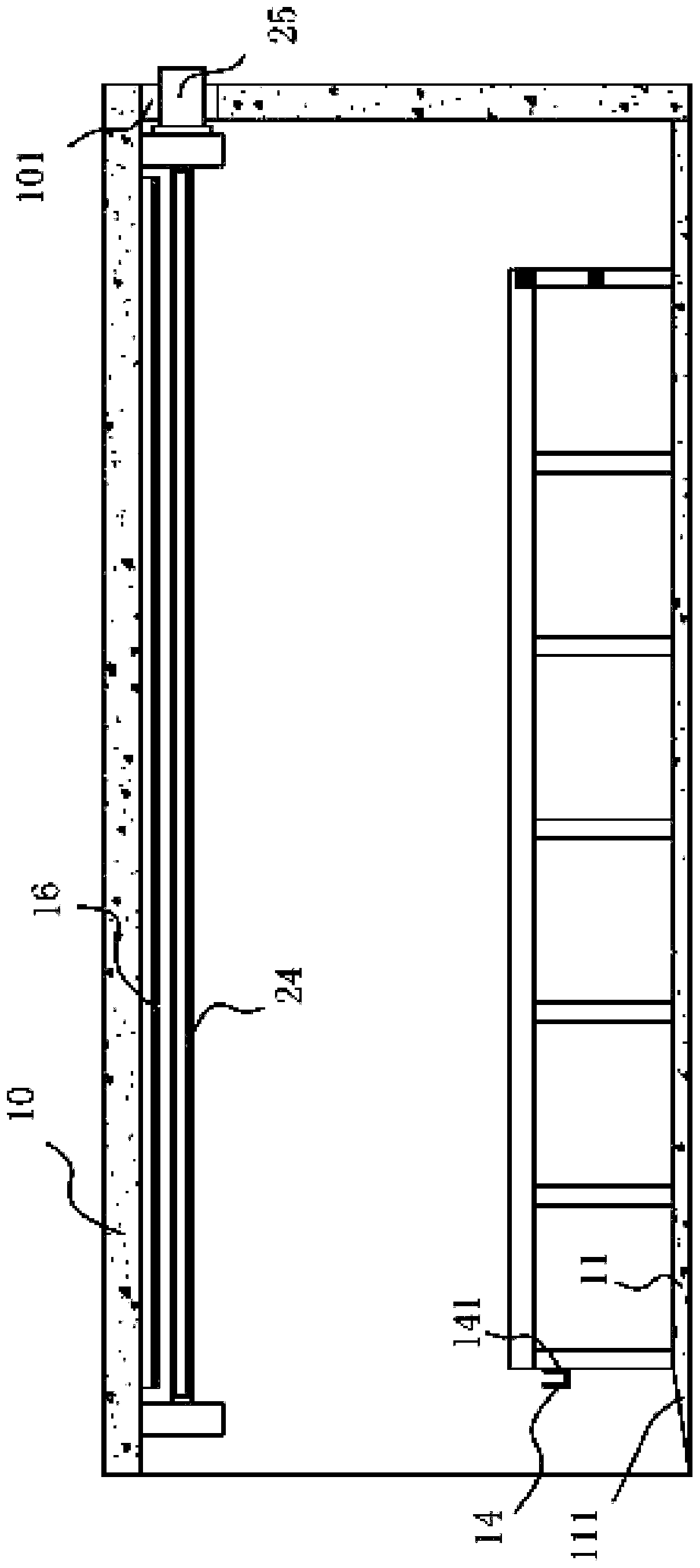

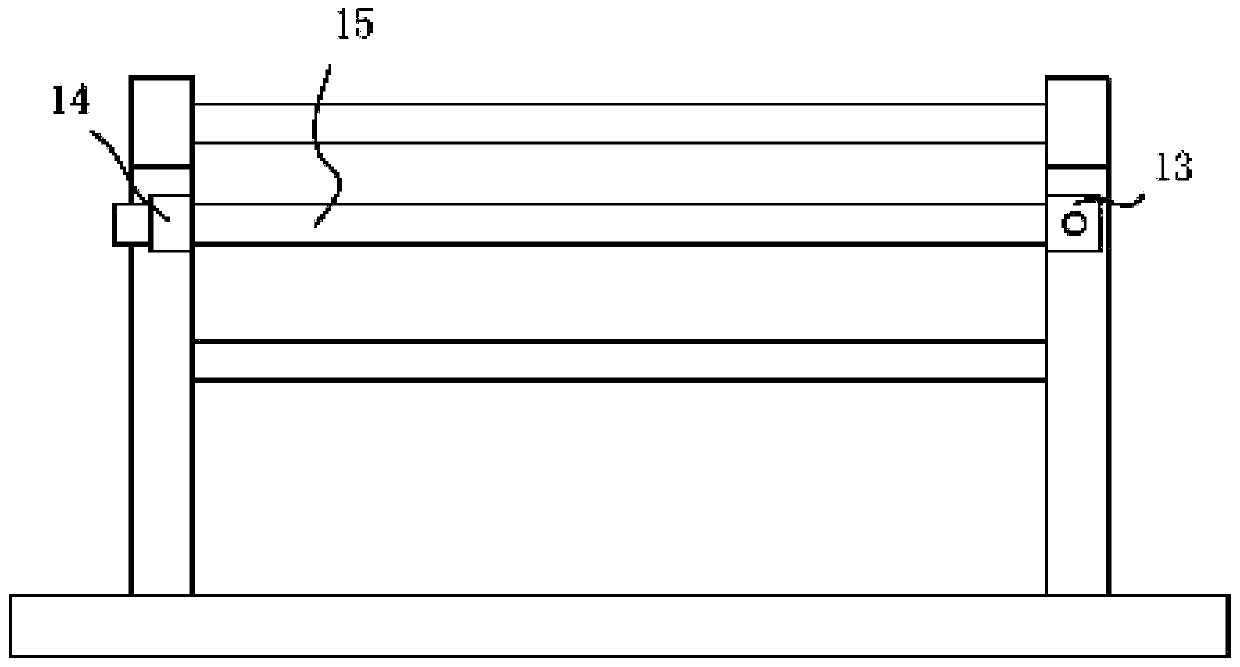

[0022] Example: see Figure 1 to Figure 4 As shown, a garbage bin outer surface cleaning mechanism includes a cleaning room body 10, and the middle part of the ground in the cleaning room body 10 is cast with a bottom plate 11;

[0023] The inner end of the placement base plate 11 and the top surfaces on the left and right sides are fixed with fences 12;

[0024] The left and right parts of the bottom surface of the top plate of the cleaning room body 10 are fixed with a transmission mechanism 20;

[0025] The bottom surface of the moving block 21 of the transmission mechanism 20 is fixed with a water liquid flushing vertical pipe 22, and the side wall of the water liquid flushing vertical pipe 22 is connected with a plurality of flushing nozzles 221, and the bottom surfaces of the two moving blocks 21 are fixed with The flushing nozzle 221 of the water liquid flushing vertical pipe 22 faces the outer wall of the trash can 1 placed on the bottom plate 11.

[0026] Further, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com