Automatic transmission vehicle engine flameout control method and device

A technology of automatic transmission and control method, which is applied in the field of flameout prevention control device and engine flameout prevention control, and can solve problems such as engine flameout easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0055] Aiming at the problem that the vehicle is prone to flameout when the existing automatic transmission vehicle is switched from neutral to D gear or R gear and then quickly steps on the accelerator of various opening degrees, the present invention proposes a method to prevent the vehicle from stalling under this condition. The engine anti-stall control method.

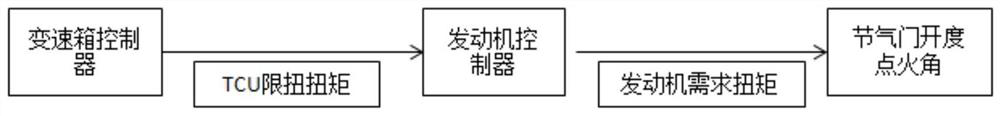

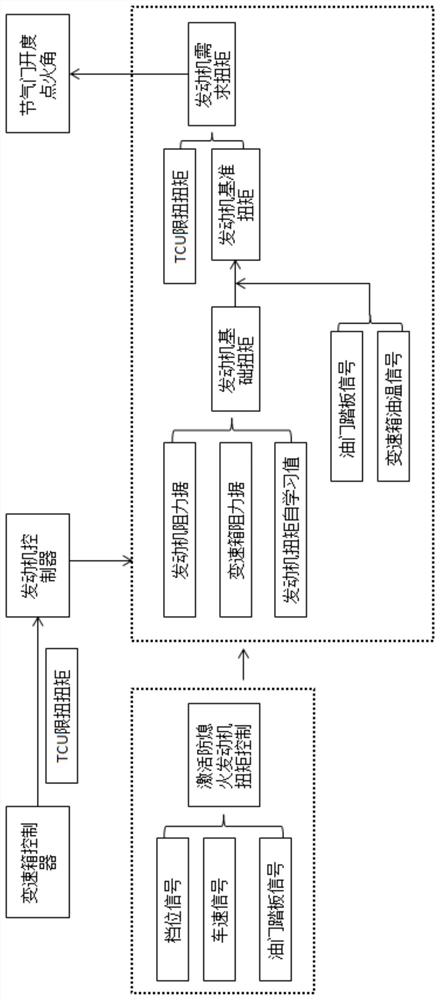

[0056] Please refer to figure 1 , figure 2 , figure 1 It is a control logic diagram of the engine flameout prevention control method for an automatic transmission vehicle provided by the present invention; figure 2 for sure figure 1 The control logic diagram for engine demand torque shown in .

[0057] The method for controlling engine flameout prevention for an automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com