Construction method using vertical formwork as pre-laid anti-stick self-adhesion waterproof roll base surface

A technology of self-adhesive waterproof membrane and pre-paved anti-adhesive, which is applied in infrastructure engineering, protection devices, gaskets, etc., can solve the problems of large labor input, high engineering cost, and long construction period, so as to ensure the construction quality , Reduce project cost, reduce the effect of pouring area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

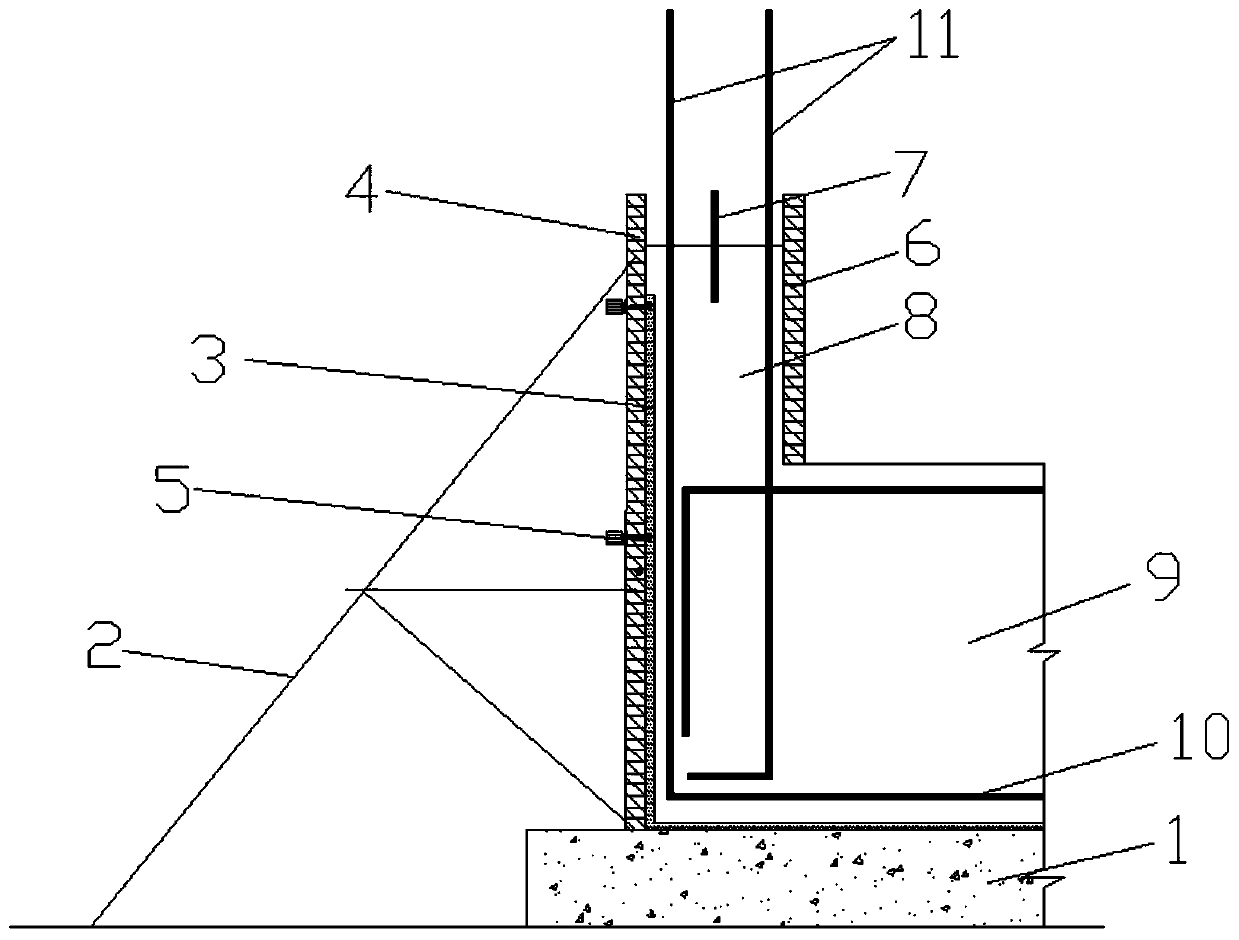

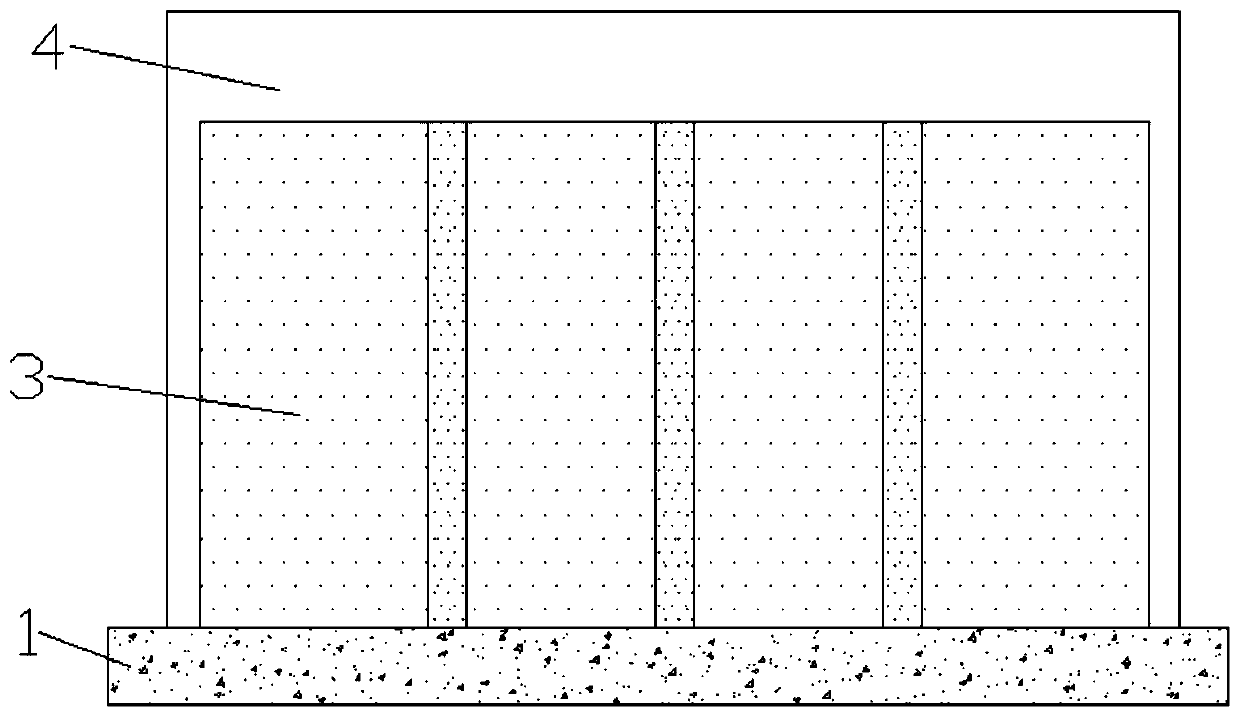

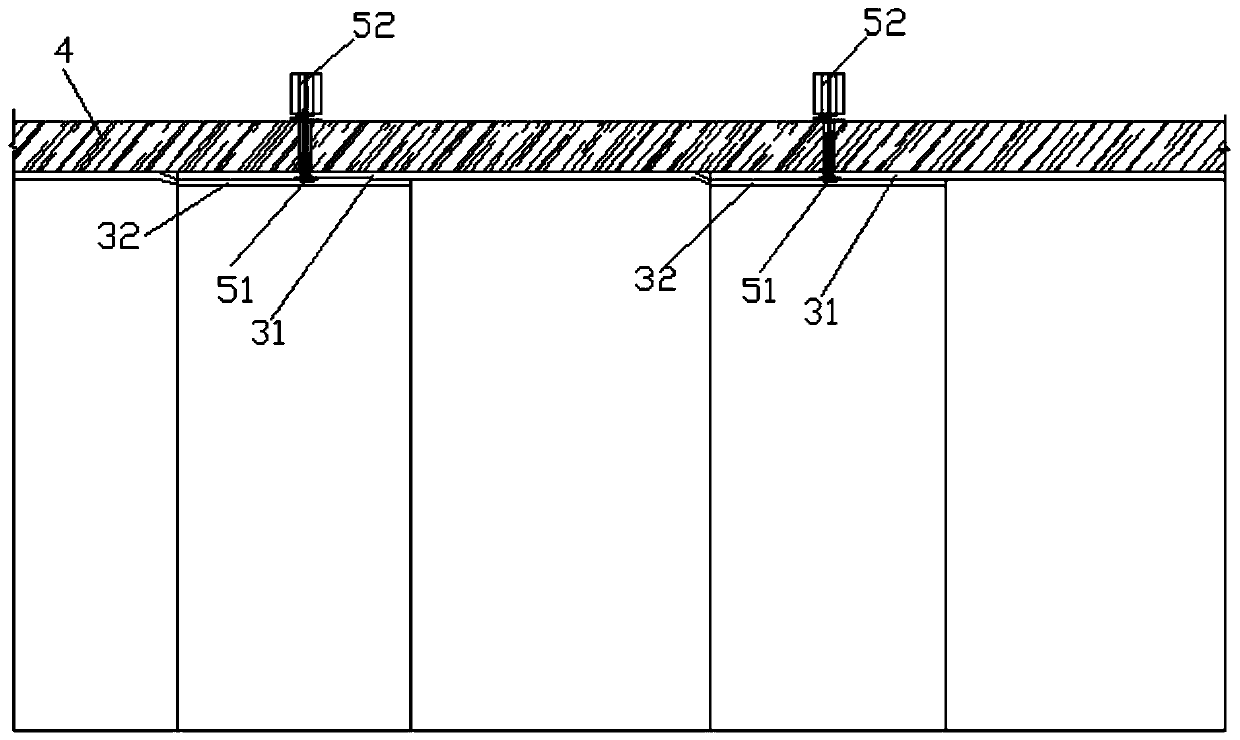

[0033] The invention provides a construction method using a vertical mold as a base surface of a pre-paved anti-adhesive self-adhesive waterproof coiled material. The technical solutions provided by the embodiments of the present invention are to solve the above-mentioned technical problems. In order to better understand the above-mentioned technical solutions, the above-mentioned technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0034] Such as Figure 1-5 As shown, a construction method using a vertical formwork as a pre-paved anti-adhesive self-adhesive waterproof membrane base surface, the specific steps are as follows:

[0035] Step S1. According to the construction drawing, set out the line and position on site, carry out earthwork excavation along the excavation sideline, and after reaching the design elevation, pour the cushion layer 1, and then set up the single-side support formwo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap