Building plastic template for replacing brick tyre membrane and installation method thereof

A technology of plastic formwork and brick membrane, which is applied in the direction of construction, building structure, formwork/formwork components, etc. It can solve the problems of long construction period of brick membrane masonry, increased earthwork excavation volume, poor overall mechanical properties, etc. problems, achieve good social and economic benefits, shorten the construction period, and facilitate and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

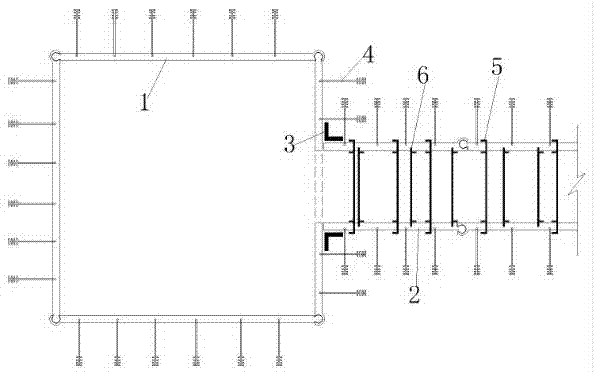

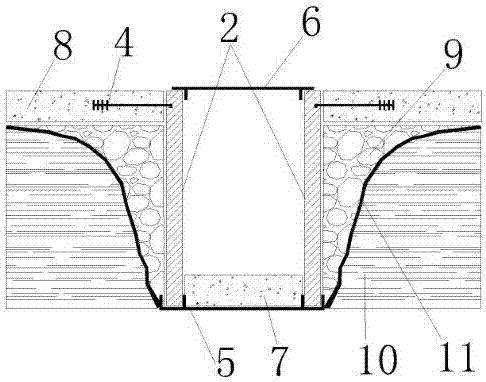

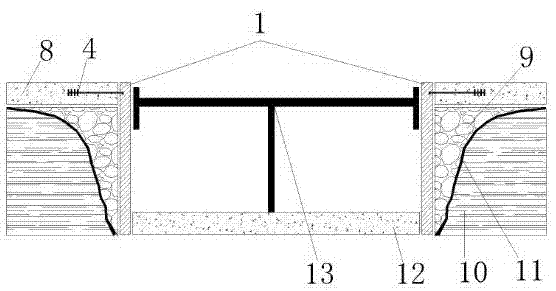

[0012] see figure 1 , a kind of building plastic formwork that replaces brick tire film and its installation method, it comprises platform cap plastic formwork 1, ground beam plastic formwork 2, cap platform plastic formwork and ground beam plastic formwork cap platform ground beam adapter 3, plastic formwork top Anchor piece 4 with the concrete cushion of the bottom slab, bottom width limiting piece 5 of ground beam formwork and top width limiting piece 6 of ground beam formwork.

[0013] The cap platform plastic formwork 1 and the ground beam plastic formwork 2 are factory-customized according to the size of the construction drawings, and the template material is made of polymer plastic material, which has the characteristics of high strength, light weight and waterproof. Snap-together installation.

[0014] Equidistant small holes are reserved...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap