Bionic micro-flow sensor and detection method thereof

A sensor, micro-flow technology, applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve problems such as poor sensitivity, achieve improved sensitivity coefficient and accuracy, high safety, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the present invention clearer and clearer, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

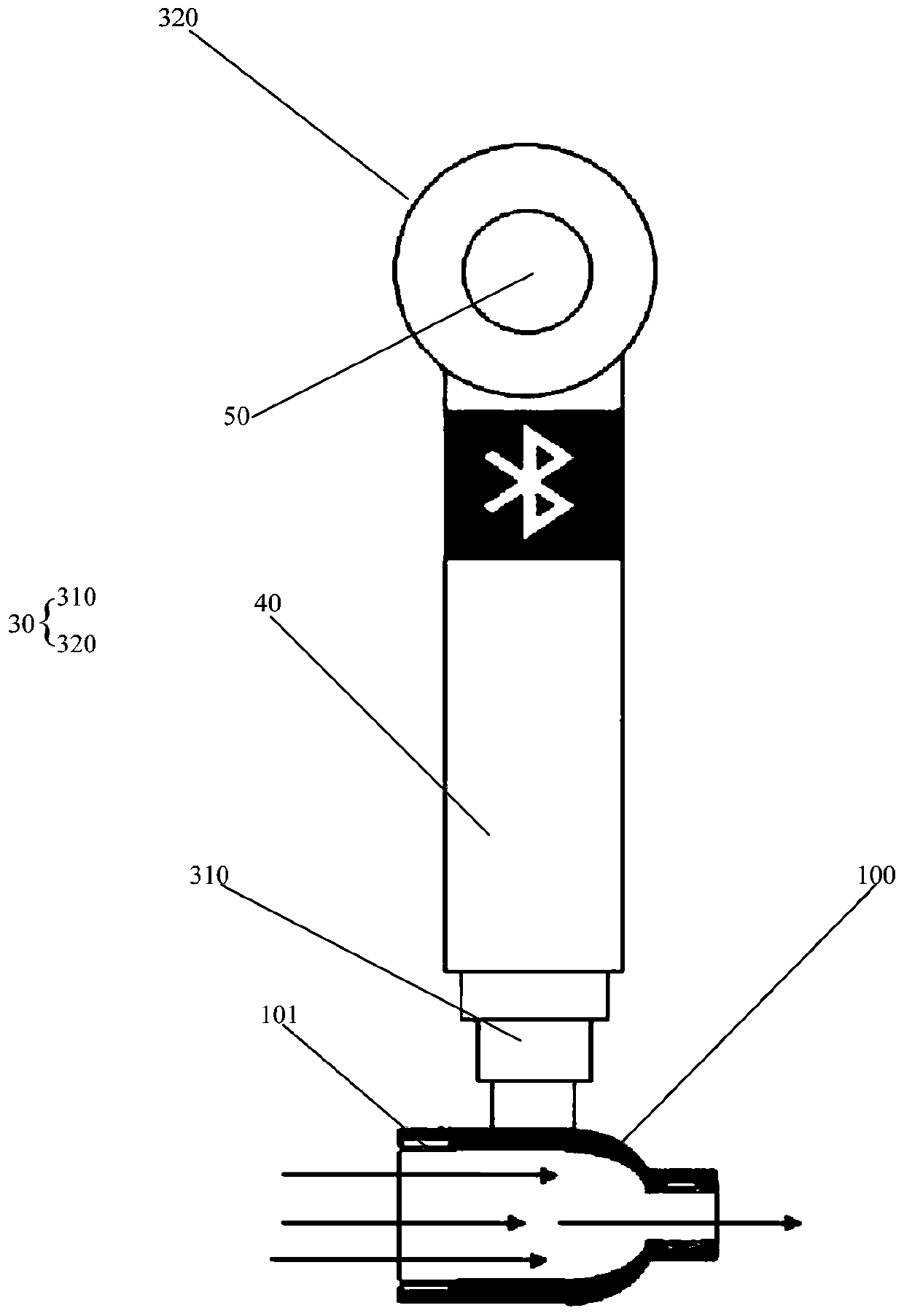

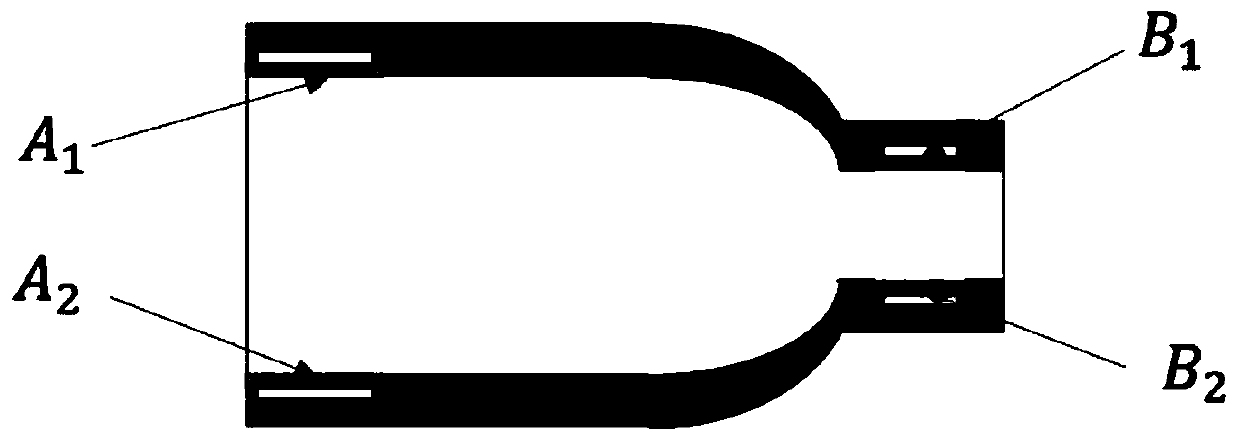

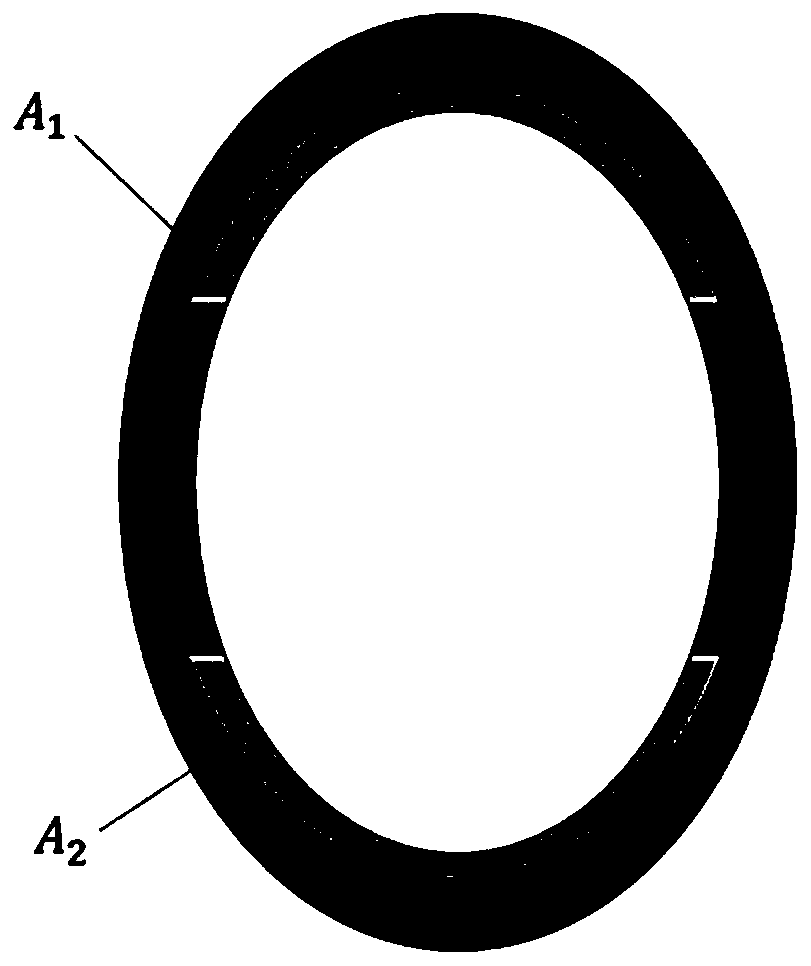

[0030] Such as figure 1 As shown, the bionic micro-flow sensor disclosed in the present invention includes a bionic pressure sensing device 10 and a circuit 20 (not shown in the figure); the bionic pressure sensing device 10 includes a housing 100 and a housing 100 The bionic baroreceptor 101; the bionic baroreceptor 101 is electrically connected to the circuit device 20; the bionic baroreceptor 101 is a bionic scorpion surface seam receptor. Wherein, the circuit includes a signal acquisition circuit and a signal processing circuit, and the signal acquisition circuit and the signal proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com