Poultry egg screening and grading system

A grading system and technology for eggs, applied in the field of egg screening and grading system, can solve problems such as low production efficiency, achieve the effects of speeding up efficiency, solving low production efficiency, and facilitating identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

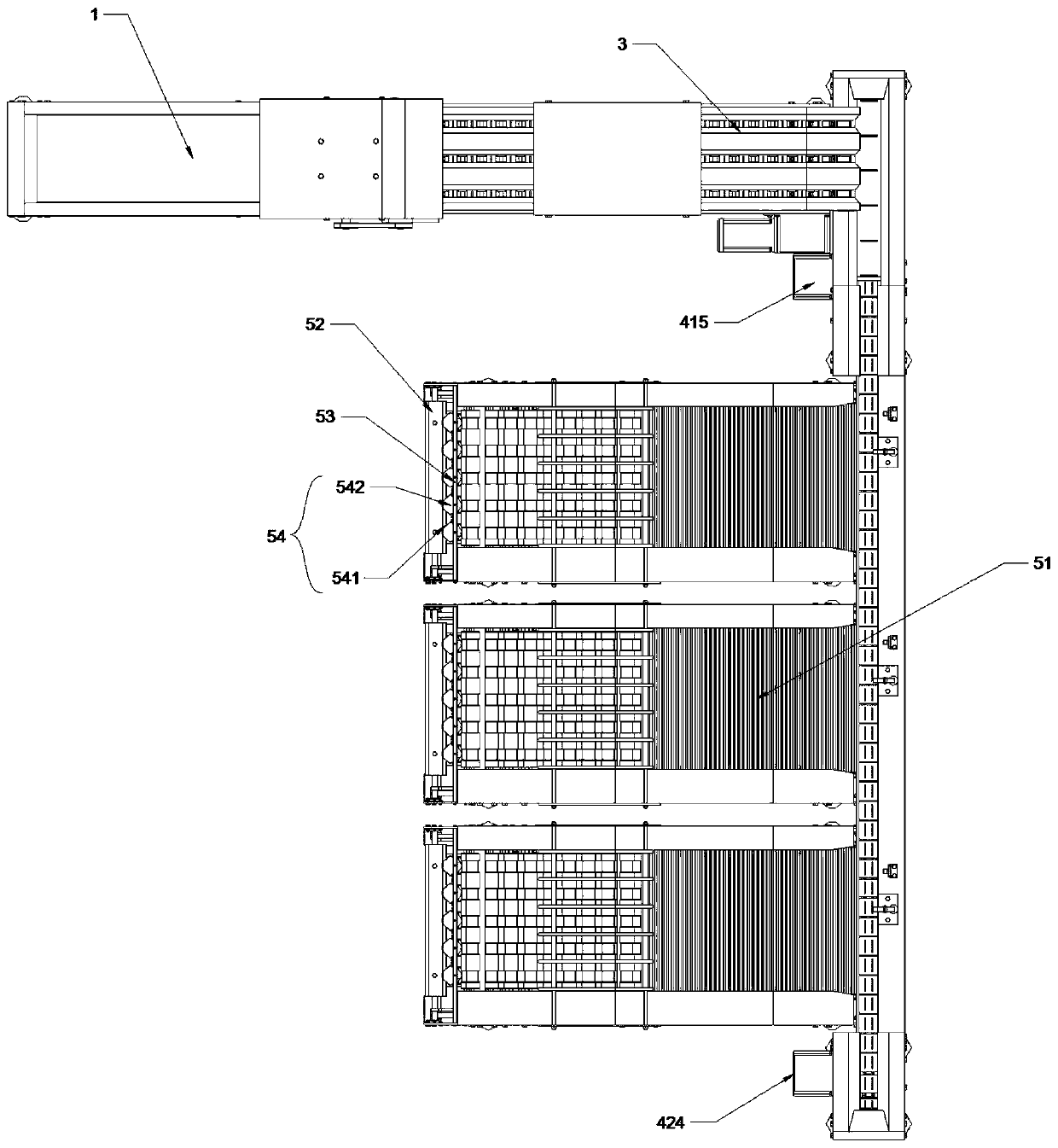

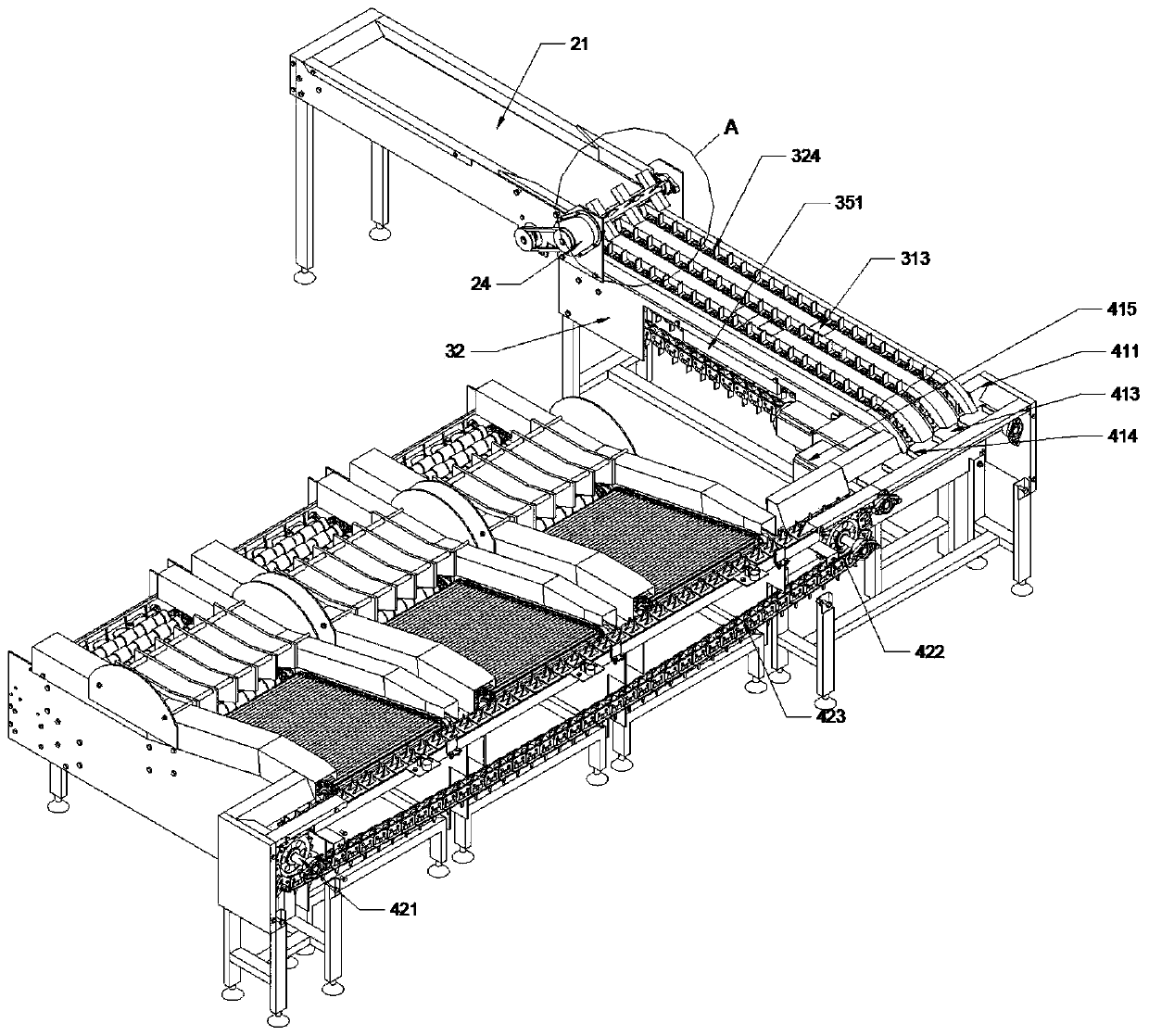

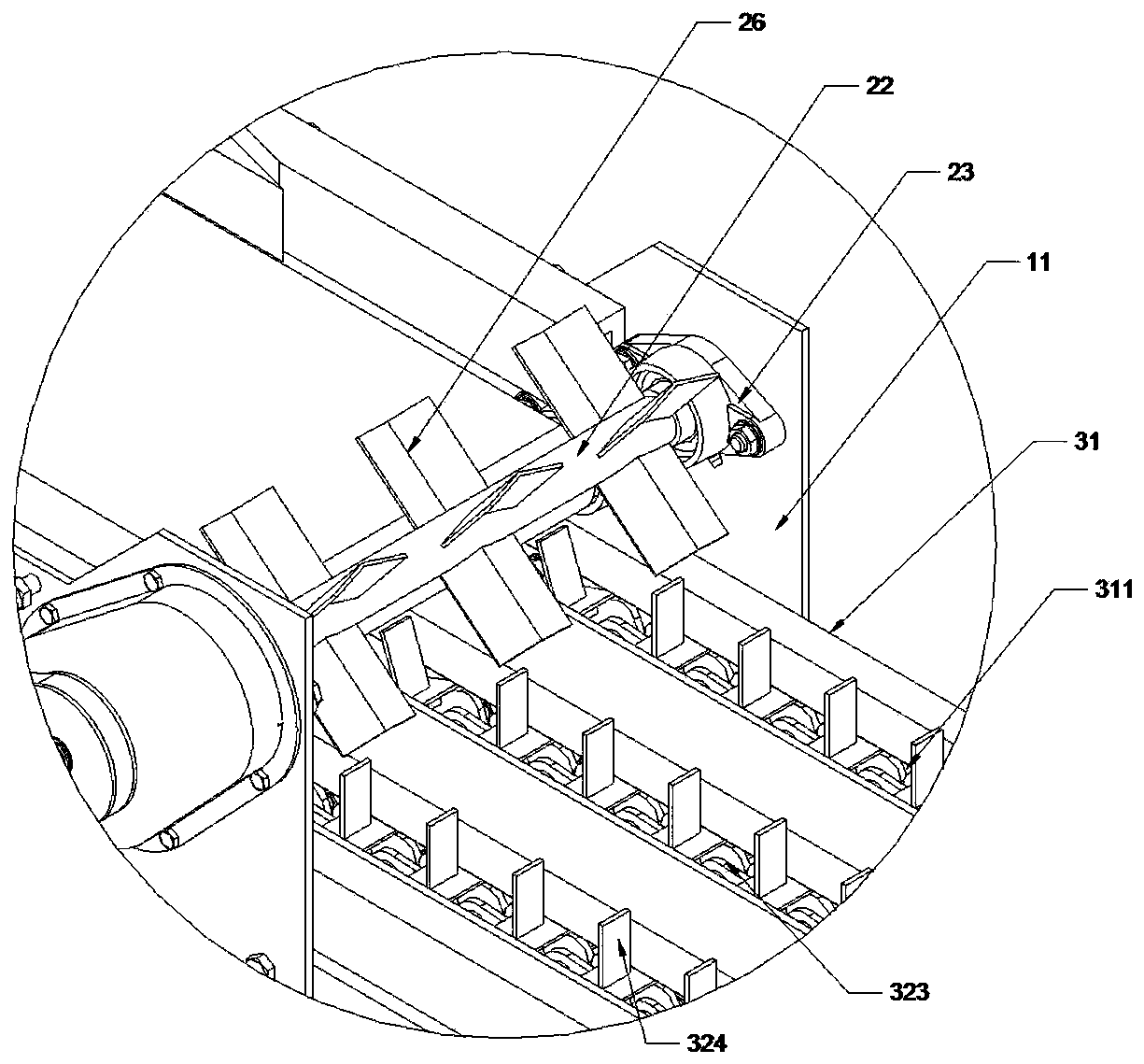

[0047] see Figure 1~3 , a poultry egg screening and grading system, including a support frame 1, and also includes a feeding device 2, an identification and screening device 3, a grading device 4, an air chamber guide device 5, and a grading device 4 that are sequentially arranged on the support frame 1 and connected sequentially. It includes a transmission device 41 docked with the identification and screening device 3. The end of the transmission device 41 away from the identification and screening device 3 is provided with a shutter 42 fixed on the support frame 1. The shutter 42 is rotated by a rotating shaft 421 and a sprocket is provided. One 422, the sprocket one 422 is provided with a conveyor chain 423, the conveyor chain 423 is provided with a plurality of and evenly distributed on its own grading baffle 43, the grading baffle 43 is docked with the transmission device one 41, and the shutter 42 is provided with There is a visual recognition sensor 2 44 for measuring...

Embodiment 2

[0052] see Figure 1~3 , a poultry egg screening and grading system, including a support frame 1, and also includes a feeding device 2, an identification and screening device 3, a grading device 4, an air chamber guide device 5, and a grading device 4 that are sequentially arranged on the support frame 1 and connected sequentially. It includes a transmission device 41 docked with the identification and screening device 3. The end of the transmission device 41 away from the identification and screening device 3 is provided with a shutter 42 fixed on the support frame 1. The shutter 42 is rotated by a rotating shaft 421 and a sprocket is provided. One 422, the sprocket one 422 is provided with a conveyor chain 423, the conveyor chain 423 is provided with a plurality of and evenly distributed on its own grading baffle 43, the grading baffle 43 is docked with the transmission device one 41, and the shutter 42 is provided with There is a visual recognition sensor 2 44 for measuring...

Embodiment 3

[0057] see Figure 1~3 , a poultry egg screening and grading system, including a support frame 1, and also includes a feeding device 2, an identification and screening device 3, a grading device 4, an air chamber guide device 5, and a grading device 4 that are sequentially arranged on the support frame 1 and connected sequentially. It includes a transmission device 41 docked with the identification and screening device 3. The end of the transmission device 41 away from the identification and screening device 3 is provided with a shutter 42 fixed on the support frame 1. The shutter 42 is rotated by a rotating shaft 421 and a sprocket is provided. One 422, the sprocket one 422 is provided with a conveyor chain 423, the conveyor chain 423 is provided with a plurality of and evenly distributed on its own grading baffle 43, the grading baffle 43 is docked with the transmission device one 41, and the shutter 42 is provided with There is a visual recognition sensor 2 44 for measuring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com