Anti-fog camera

A camera and anti-fog technology, applied in image communication, television, optics, etc., can solve the problems of long time, inconvenient to clean water mist, and reduce the clarity of camera monitoring, so as to increase the defogging area and improve the defogging. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

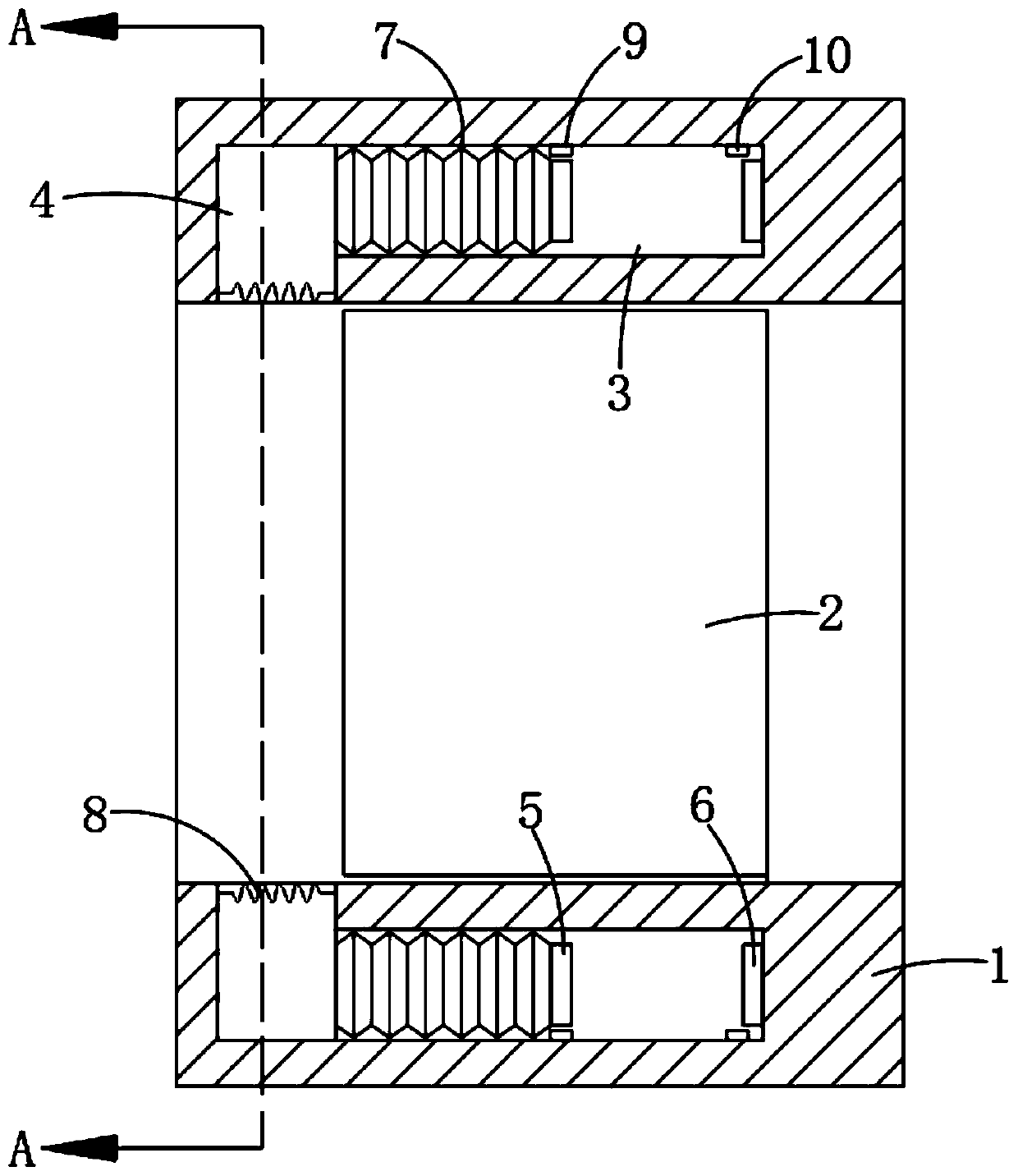

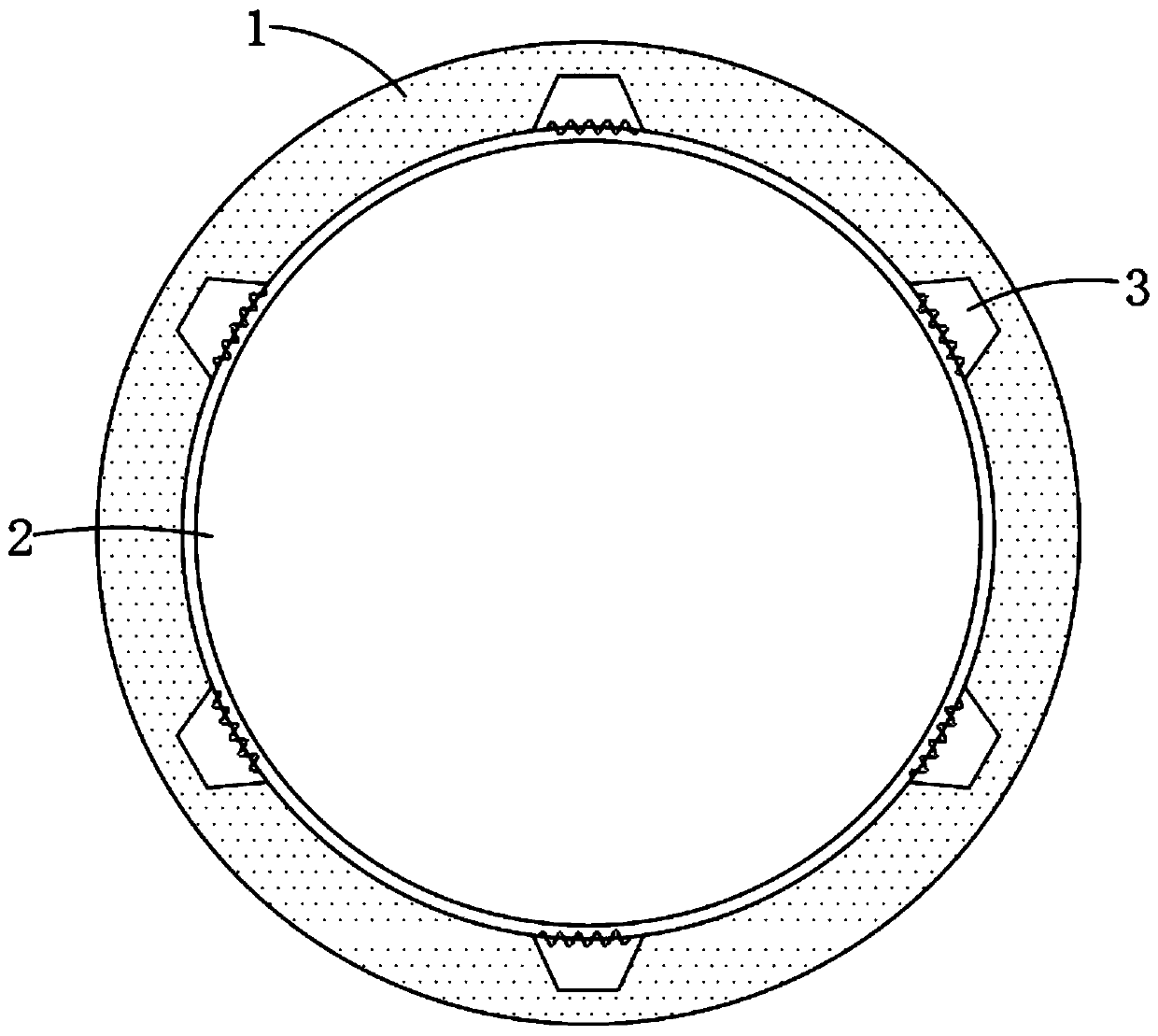

[0021] refer to Figure 1-2 , an anti-fog camera, comprising a lens barrel 1, a lens 2 is embedded in the lens barrel 1, a plurality of strip grooves 3 are provided on the side wall of the lens barrel 1 at equal intervals along its circumference, and a plurality of strip grooves 3 are provided on the side wall of the lens barrel 1 There are a plurality of wedge-shaped air outlets 4 communicating with the bar-shaped groove 3. The wedge-shaped air outlets 4 can make the discharged air cover the lens 2. The lens barrel 1 is embedded with a power generation assembly composed of a plurality of thermoelectric power generation sheets connected in series. Each The wedge-shaped air outlets 4 are embedded with heating wires 8 electrically connected to the power generation components, and the inner wall of the strip groove 3 is fixedly connected with a telescopic airbag 7, and a driving device for driving the telescopic airbag 7 to expand and contract is installed in the strip groove 3. ...

Embodiment 2

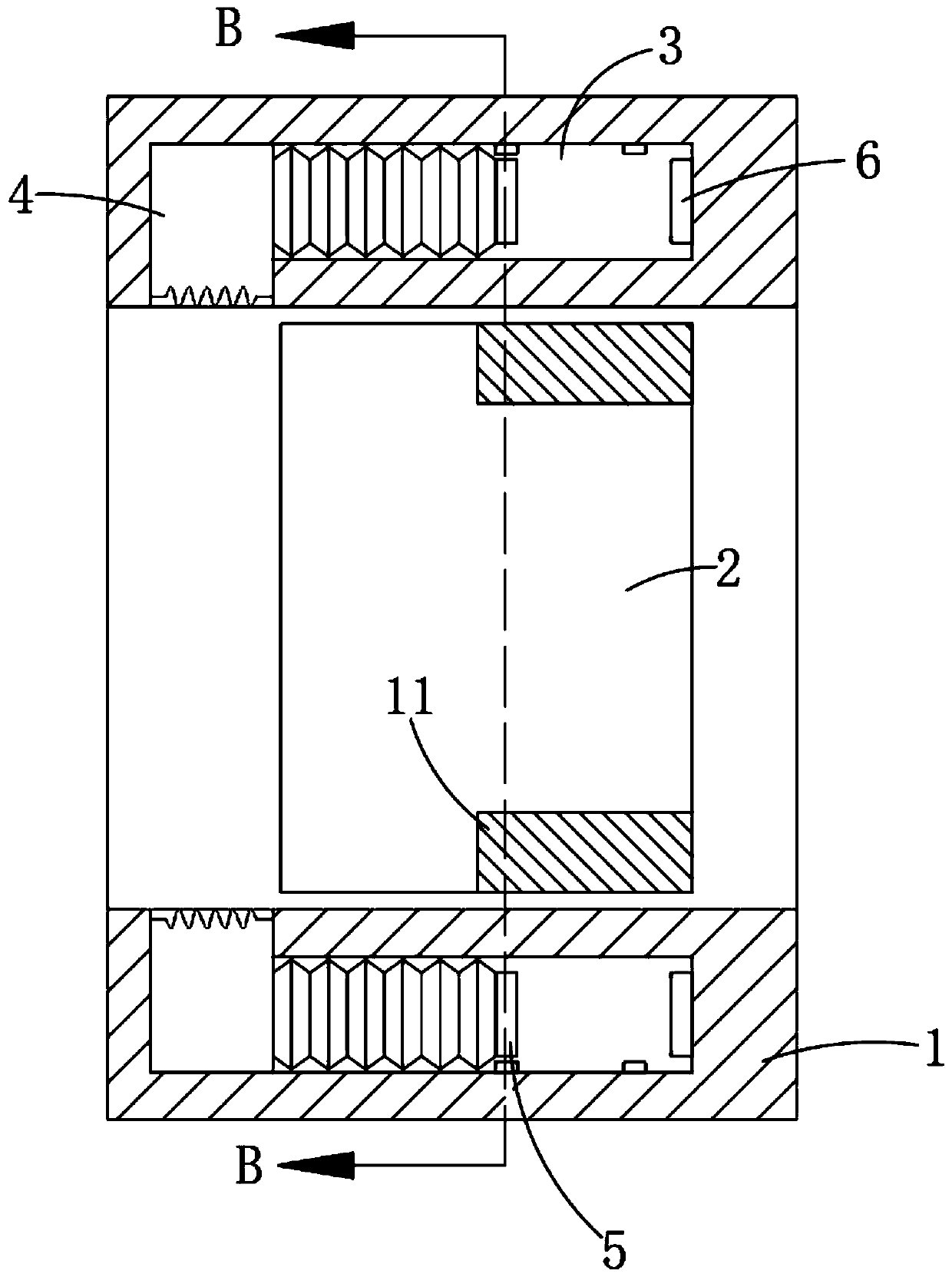

[0025] refer to Figure 3-4 , different from Embodiment 1, the lens 2 is sealed and slid with the inner wall of the lens barrel 1 to ensure that the lens 2 can rotate along its central axis without hindrance, and the circumferential side wall of the lens 2 is embedded with an arc corresponding to the electromagnet 5 Magnetic block 11, and the arc-shaped magnetic block 11 and the electromagnet 5 magnetic poles repel each other.

[0026] In this embodiment, when the electromagnet 5 is energized, it will generate a repulsive force on the arc-shaped magnetic block 11, so that the lens 2 rotates counterclockwise at a certain angle. When the electromagnet 5 is powered off, the iron core in the electromagnet 5 can attract the arc-shaped The magnetic block 11 drives the lens 2 to rotate clockwise for a certain angle. When the electromagnet 5 is energized again, the lens 2 will rotate counterclockwise for a certain angle. The hot air can cover the surface of the lens 2 more comprehens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com