A kind of ship side thruster installation process

An installation process and ship technology, applied in the direction of ships, etc., can solve the problems of very high requirements for dynamic positioning systems, complicated installation and commissioning process, high adjustment time and cost, and achieve the goal of saving installation and adjustment time, low cost, and high installation process accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

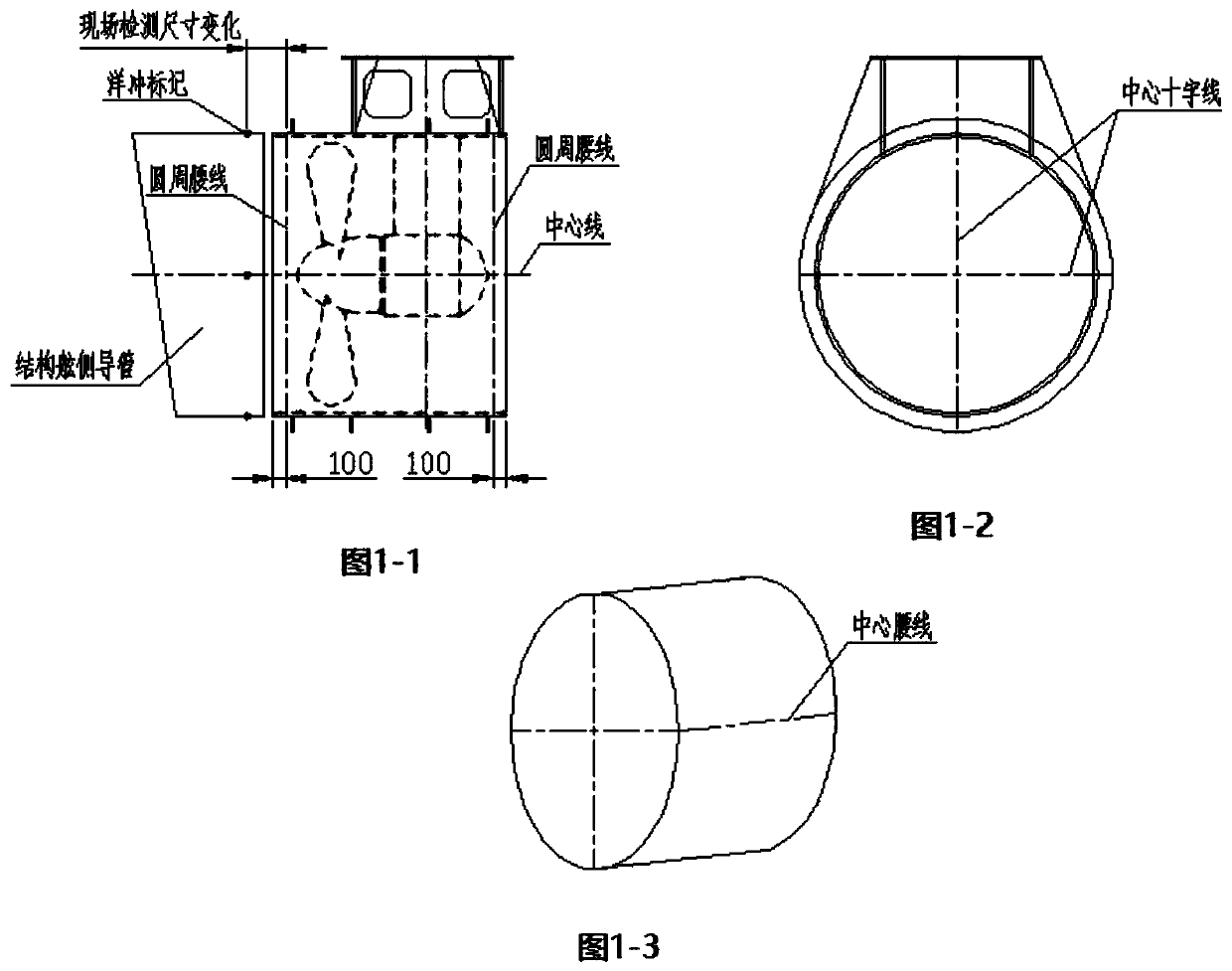

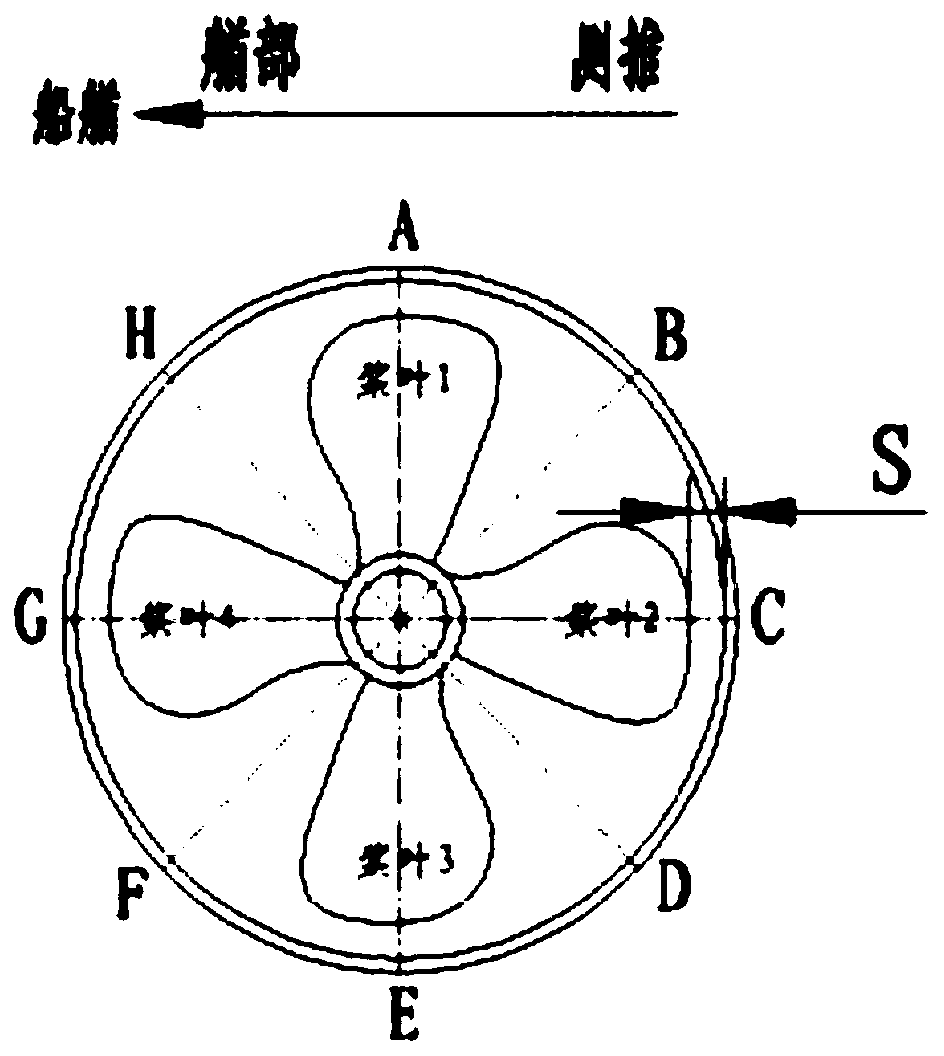

[0024] Such as figure 1 As shown, taking the Haiyang Shiyou 278 semi-submersible self-propelled engineering ship as an example, there are tube-type variable frequency bow thrusters installed in the respective side thruster coffers. In the embodiment of the present invention, the side thruster is a vertical variable frequency motor Take the drive as an example, its rated input power is 2000kW, the material of the propeller is nickel-aluminum bronze, the power of the motor: 2000kW; speed: 0-1000rpm, protection level: IP56.

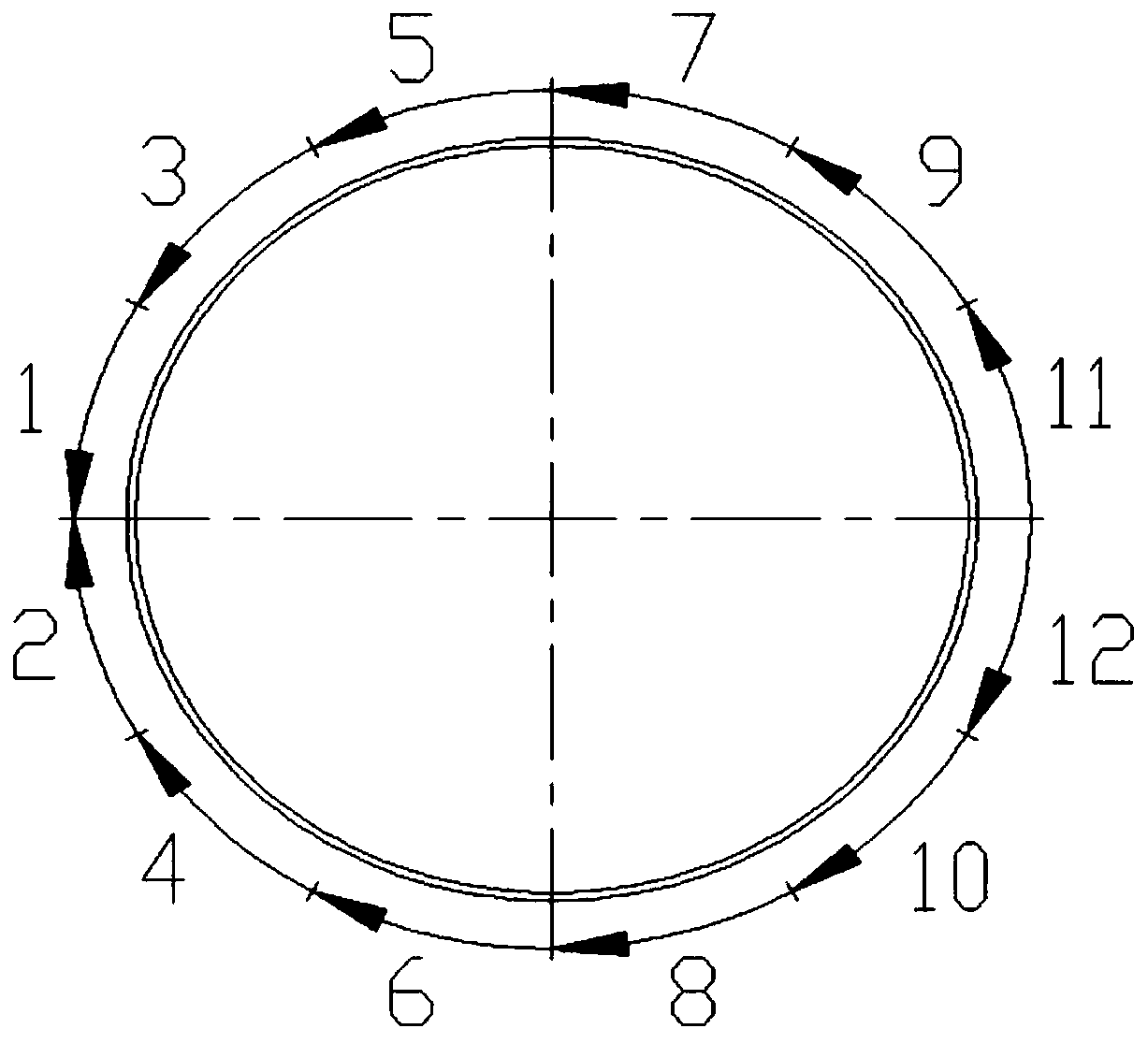

[0025] The side thrusters can only be installed after the welding of the segmented structure is completed. The installation of the side thruster is mainly that the side thruster duct is docked with the outboard extension duct of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com