An installation process of a ship's retractable propeller

An installation process and propeller technology, applied in the direction of ships, etc., can solve the problems of high cost, difficulty and time-consuming adjustment time, and achieve the effect of saving installation adjustment time, low cost and improving installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

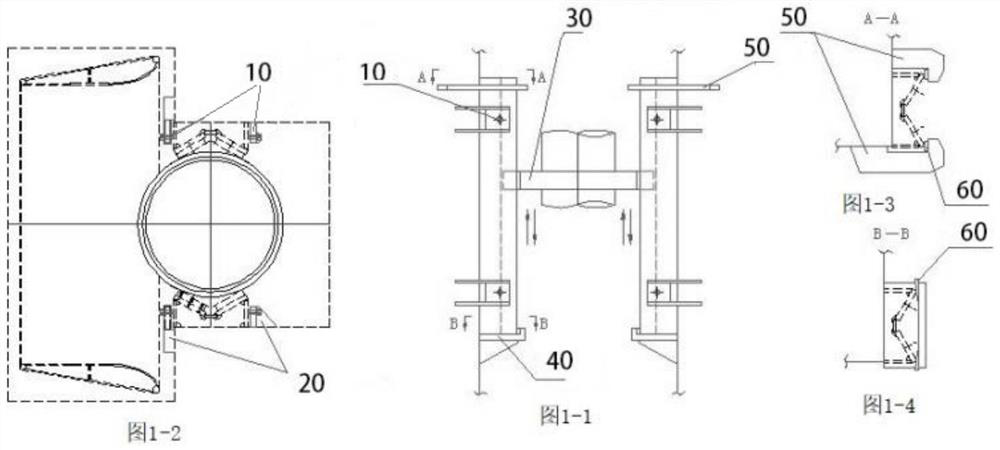

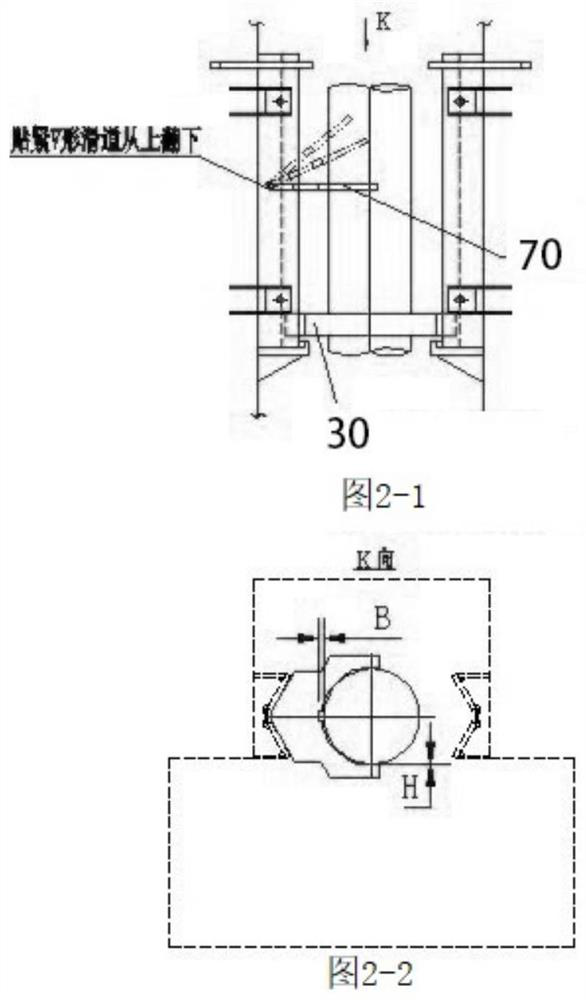

[0016] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0017] The present invention takes Offshore Oil 278 platform as an example. Before the installation starts, the on-site processing method of the mechanical power milling head after welding is adopted to ensure the accuracy of the flange plane on which the retractable propeller is installed. The value was measured using a laser flatness measuring device (Easy-Laser).

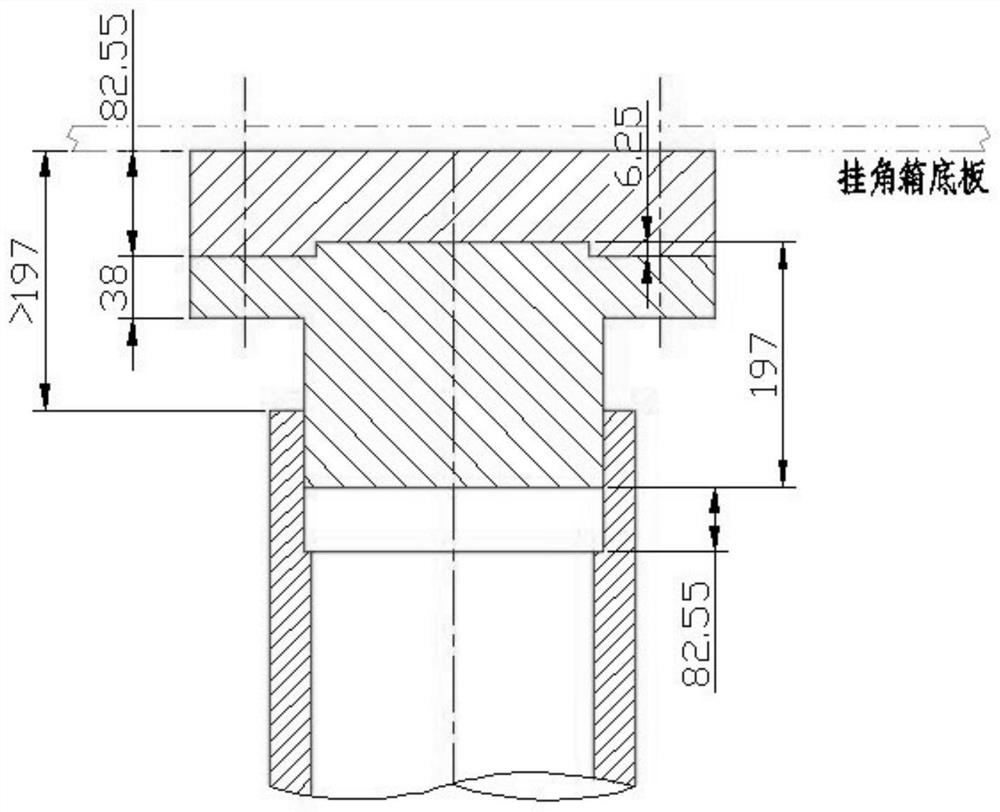

[0018] Step 1. On-site processing of the flange plane of the retractable thruster installation casing.

[0019] Step 1.1. The main body of the retractable thruster should be installed on the plane of the hull casing flange, and the flatness of the casing flange should be 0.508mm. When the bolts are tightened, use a 0.05mm feeler gauge to check that 70% of the circumference cannot be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com