Concave-convex texture mold and manufacturing method and application thereof

A technology of concave-convex texture and production method, which is applied in the directions of information-carrying cards, printing of special varieties of printed matter, and processes for producing decorative surface effects, etc. Problems such as insufficient texture, to achieve the effect of enhancing artistic expression and fine texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

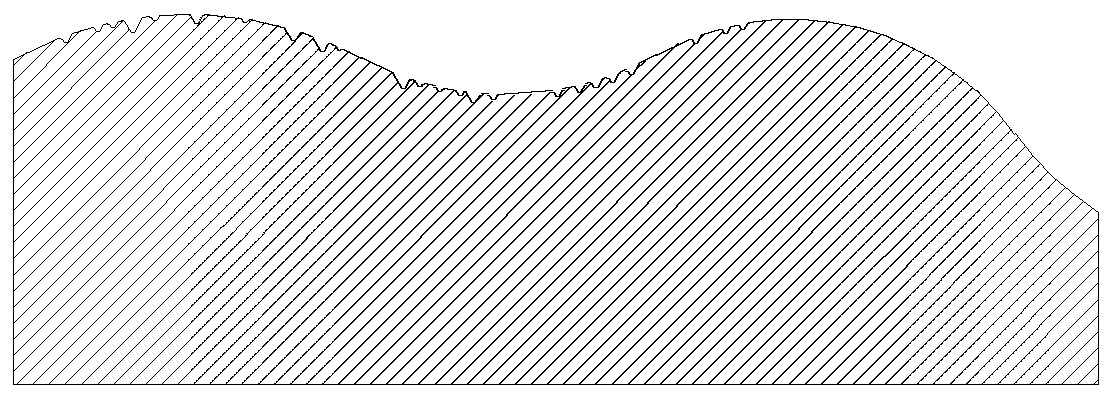

[0052] Such as image 3 , Figure 4 As shown, an important innovative point of the concave-convex texture mold in this embodiment is that the concave-convex texture is distributed on the concave-convex mold surface of the mold. image 3 It is a cross-sectional view of a mold with a concave-convex surface. In the figure, a plurality of notches with different lengths, depths, widths, strips, transition structures, and bottom structures are distributed on the concave-convex surface. Figure 4 for image 3 The enlarged schematic diagram of the middle part, in which the depth, width, slope, and radian of the sharp corners are specifically marked.

[0053] Specifically refers to, a kind of concave-convex texture mould, is provided with concave-convex texture on the molding surface of mold, and described molding surface is the relief surface of concave-convex, namely concave-convex molding surface; The notches with different transitional structures and bottom structures are formed...

Embodiment 2

[0089] This embodiment is further optimized on the basis of embodiment 1, as Figure 9 The technological process of the press processing of a metal product shown is: preparation of gold and silver flat cake, embossing with a concave-convex texture mold, inspection and packaging of the embossed metal product, and storage of the finished product.

[0090] Among them, such as Figure 9 As shown, the method for making a concave-convex texture mold includes pattern design, mechanical engraving, laser sandblasting, and manual repair and grinding. The method for making a concave-convex texture mold includes the following steps:

[0091] Step S1: first design a dot-line pattern composed of points and lines according to the pattern to be presented, and then use a 3D design software to perform 3D relief modeling on the dot-line pattern to generate a 3D relief model;

[0092] Step S2: Process a profile on the mold according to the three-dimensional relief model; the profile is a flat su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap