Self-resetting energy dissipating steel column base joint

A self-resetting and energy-dissipating technology, applied in building types, buildings, building components, etc., can solve the problems of unusable structural performance, residual structural deformation, economic losses, etc., to control the repair cost, strong self-resetting ability, reduce Effects of Residual Deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

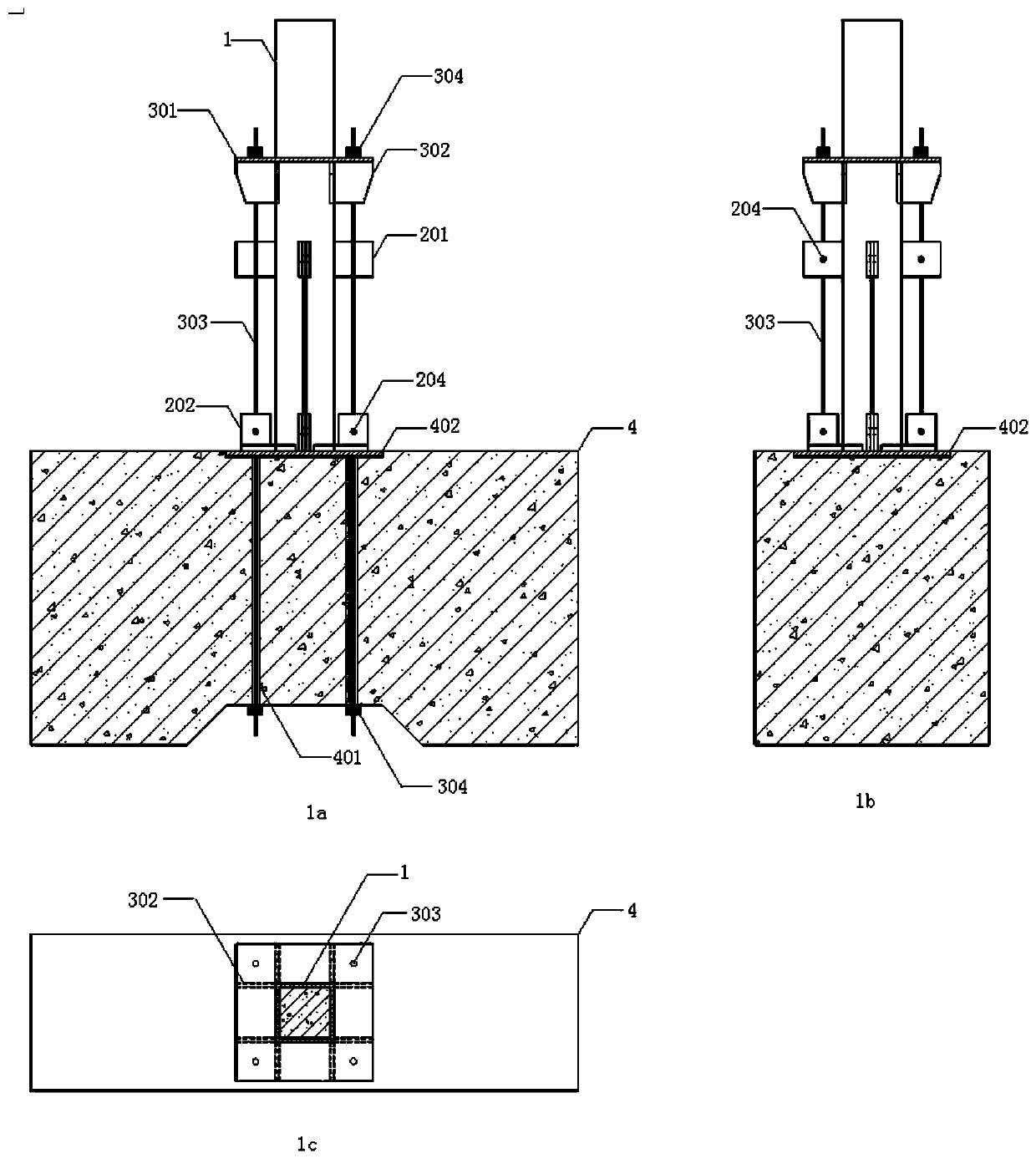

[0026] See figure 1 This embodiment discloses a self-resetting energy-dissipating steel column foot node, which includes a steel column 1, a yielding energy-dissipating body 2, a self-resetting system 3, and a concrete foundation beam 4.

[0027] A steel plate 402 is buried on the top of the concrete foundation beam 4. Four steel sleeves 401 are embedded in the beam body of the concrete foundation beam 4. See Figure 5 The top steel plate 402 is provided with a butt-through connection hole 4021 at the corresponding position of the steel sleeve 401 for the pre-stressed steel strand 303 to pass through. A shear key 403 is also arranged on the top steel plate 402 of the foundation. The shear key 403 is welded to the top steel plate 402 of the foundation.

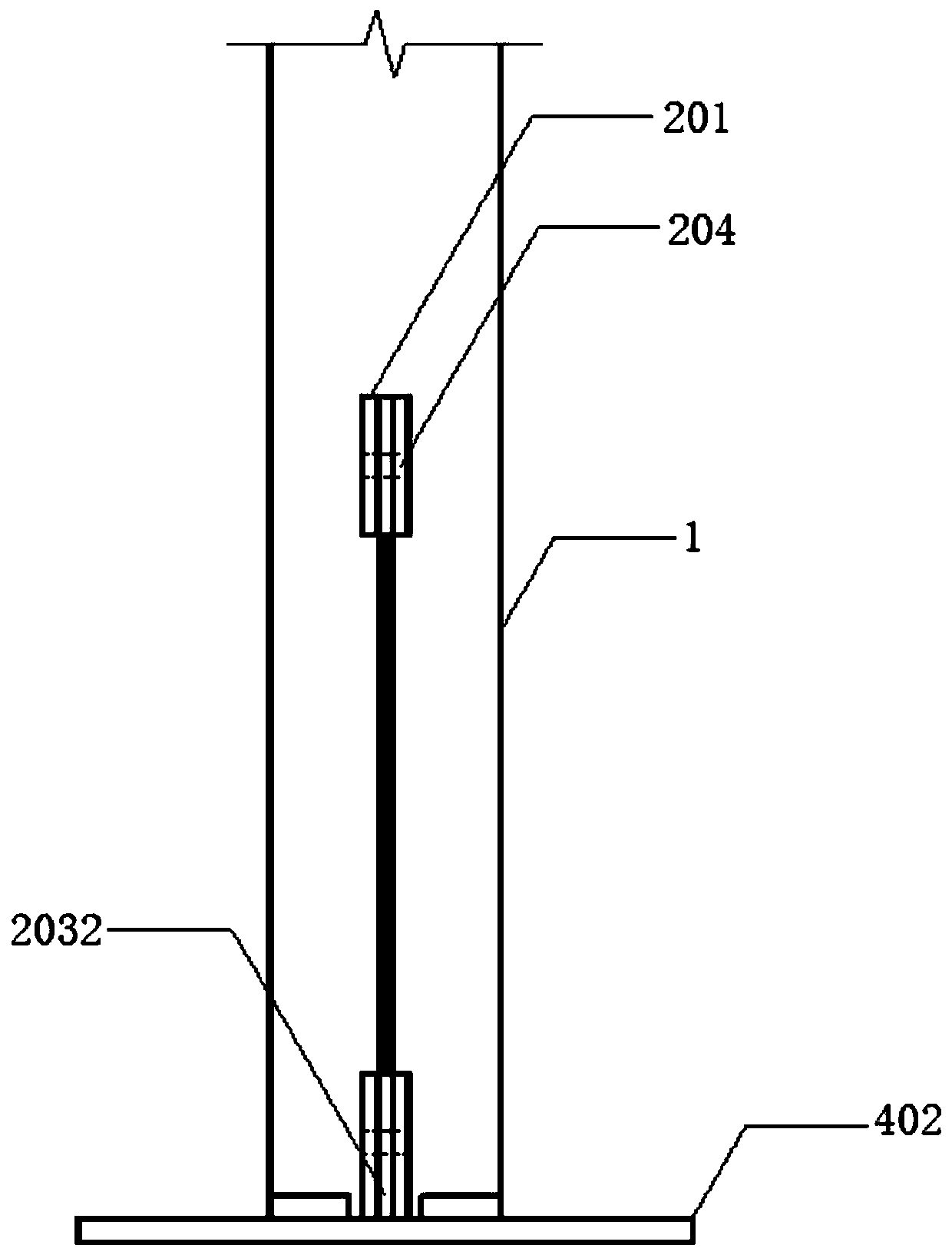

[0028] The steel column 1 is a rectangular steel tube. The inner cavity of the steel column 1 is filled with concrete. The bottom of the steel column 1 is also provided with a column foot steel plate. The steel column 1 is ver...

Embodiment 2

[0033] This embodiment provides a self-resetting energy-dissipating steel column foot node, which includes a steel column 1, a yielding energy-dissipating body 2, a self-resetting system 3, and a concrete foundation beam 4.

[0034] A top steel plate 402 is buried on the top of the concrete foundation beam 4. A plurality of steel sleeves 401 are embedded in the beam body of the concrete foundation beam 4. The base top steel plate 402 is provided with a butt-through connection hole 4021 at the corresponding position of the steel sleeve 401 for the prestressed steel strand 303 to pass through.

[0035] The steel column 1 is a rectangular steel tube. The steel column 1 is vertically arranged on the upper surface of the concrete foundation beam 4. A yield energy dissipator 2 is respectively arranged on the four lateral walls of the steel column 1.

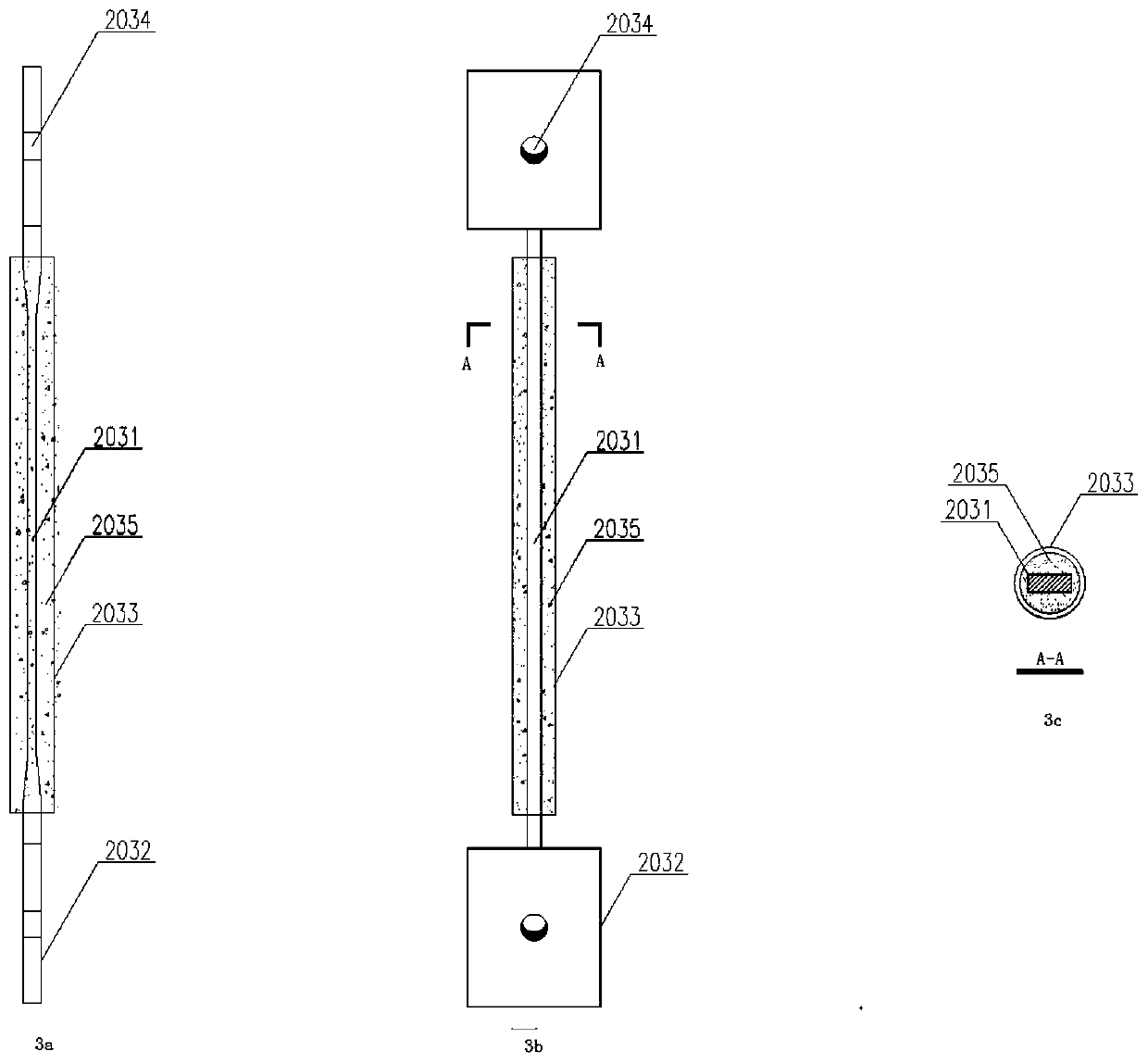

[0036] Each yielding energy dissipation body 2 includes two upper connecting plates 201, two lower connecting plates 202, an anti-yieldin...

Embodiment 3

[0039] This embodiment provides a self-resetting energy-dissipating steel column foot node, and the main structure is the same as that in the second embodiment. Wherein, a stiffening rib 302 is also welded between the steel column 1 and the prestressed rib connecting plate 301.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com