Metal Rubber Dampers for Fabricated Flexible Frame Joints

A metal rubber and damper technology, applied in protective buildings/shelters, building types, buildings, etc., can solve the problems of damping device failure, weakened energy dissipation capacity, and large temperature influence of viscoelastic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

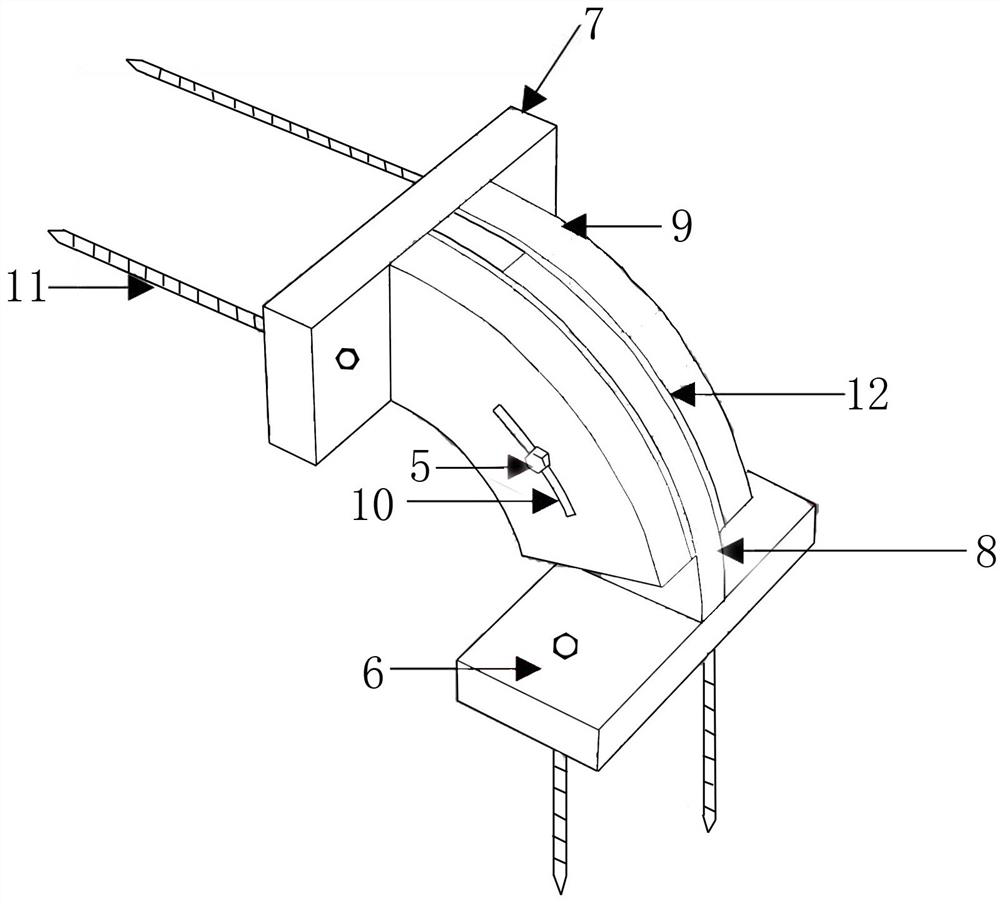

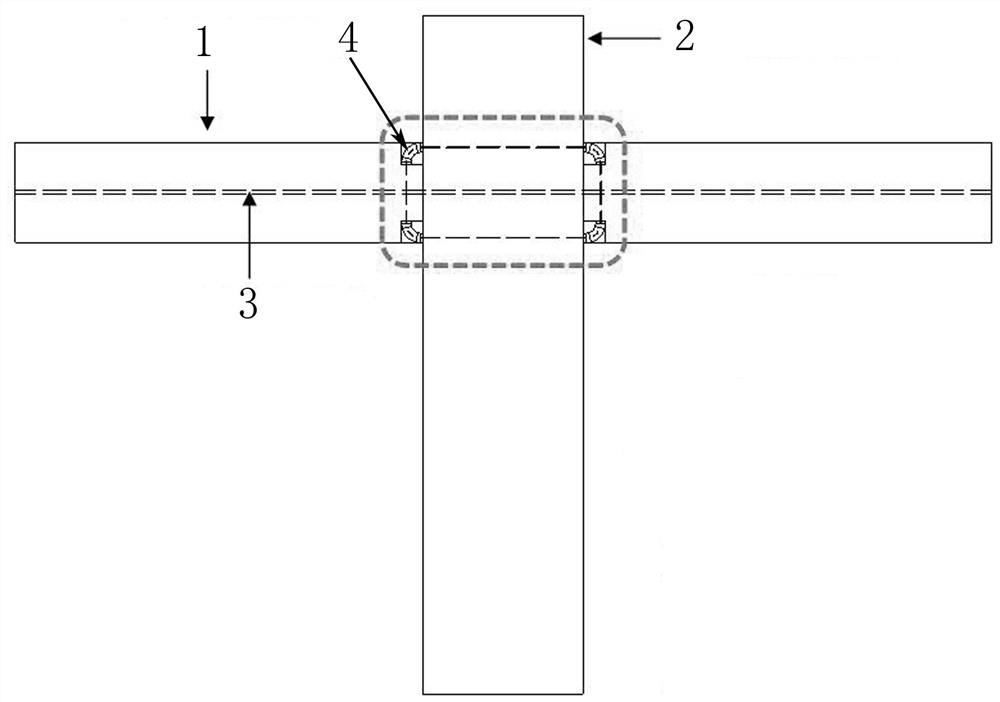

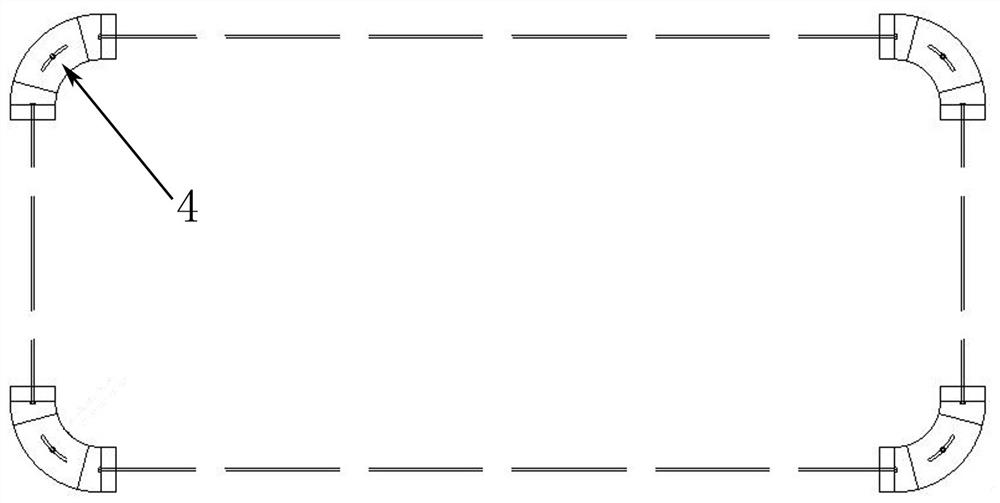

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] A metal-rubber damper for fabricated flexible frame joints, such as figure 1 As shown, the beam connecting plate 6 and the column connecting plate 7 are included, the beam side shear fan plate 8 is vertically fixed on the beam connecting plate 6, the column side connecting fan plate 9 is vertically fixed on the column connecting plate 7, and the beam side shear fan plate 9 is vertically fixed on the column connecting plate 7. Corresponding arc-shaped chute 10 is provided on the plate 8 and the column-side shear fan 9, and the positioning high-strength bolt 5 passes through the arc-shaped chute 10 to connect the beam-side shear fan 8 and the column-side connection fan 9, A metal rubber friction gasket 12 is provided between the shear fan plate 8 on the beam side and the connecting fan plate 9 on the column side.

[0024]By installing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com