A Method for Broaching Deformation of Large Axial Tenon and Groove Notch and Eliminating the Edge

A tenon-groove and axial technology, which is applied in the field of large-scale axial tenon-groove notch broaching deformation and the elimination of knife edges, can solve the problems of unqualified dimensions, parts quality and processing cycle, and large dimensional changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

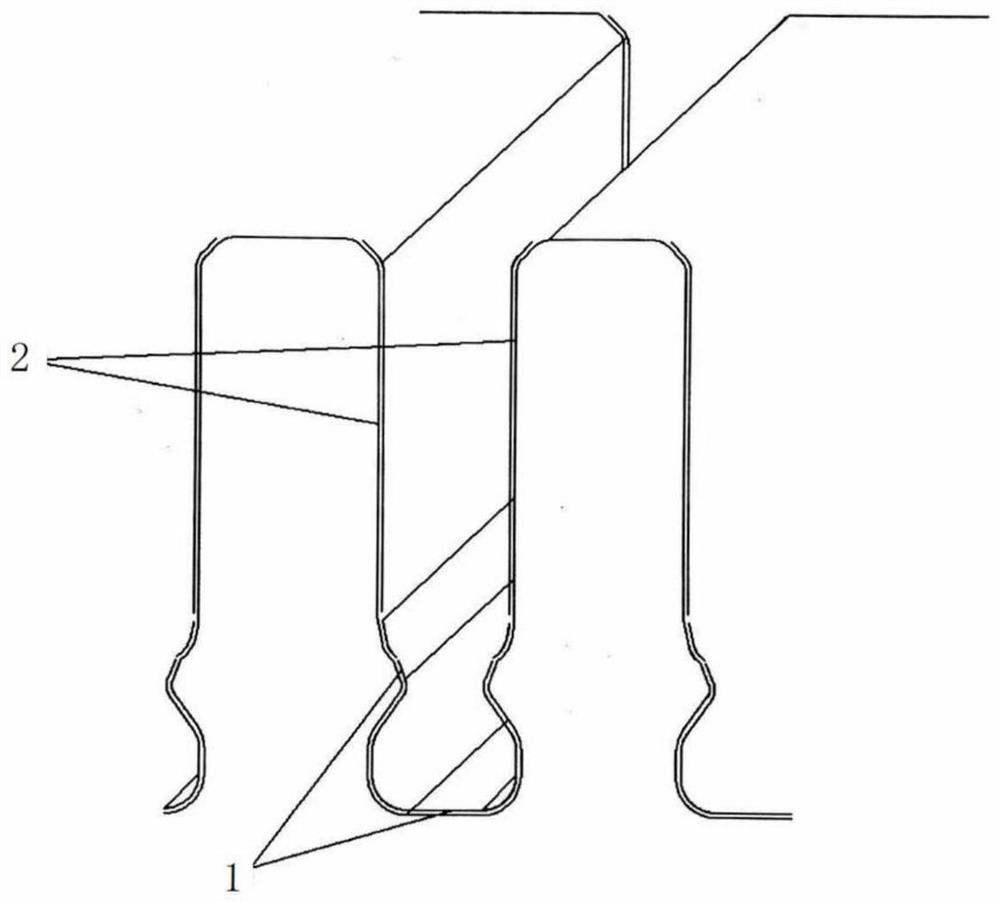

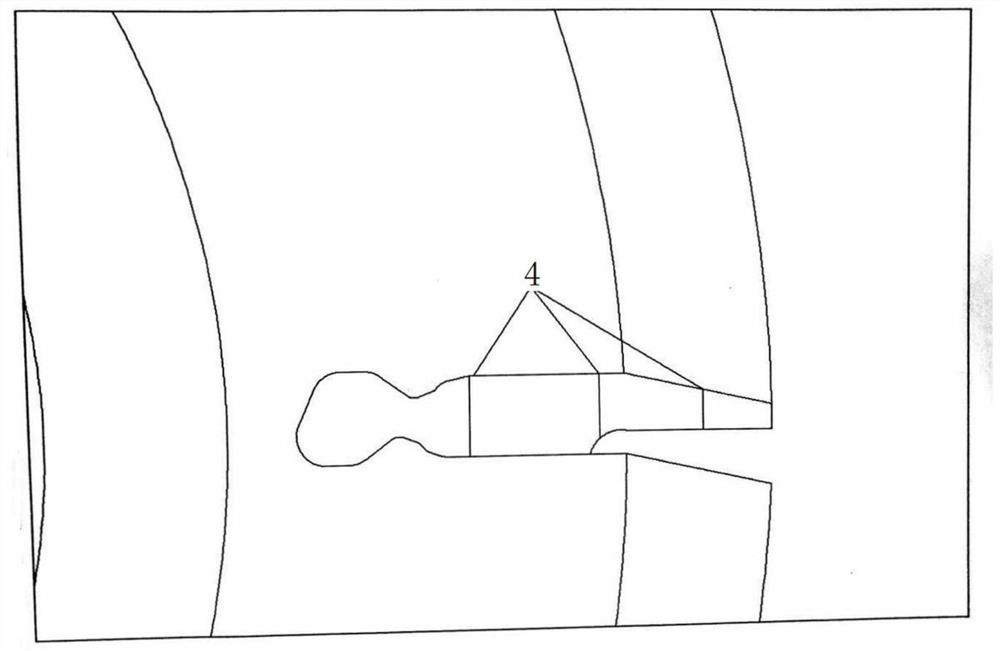

[0019] according to Figure 1-4 As shown, a method for broaching deformation of large-scale axial tenon-groove notches and eliminating the edge of the knife, for the large-scale axial tenon-groove structure made of TC4 titanium alloy material, it is divided into tenon-groove-1-groove main body and The outer flash 2 structure of the wheel disc; and the length of the flash 2 should be greater than 70mm, and the axial thickness should be 5-22mm;

[0020] The mortise 1 slot is used to install the blade, and its working surface is closely matched with the blade;

[0021] The structure of outer flash 2 is thin;

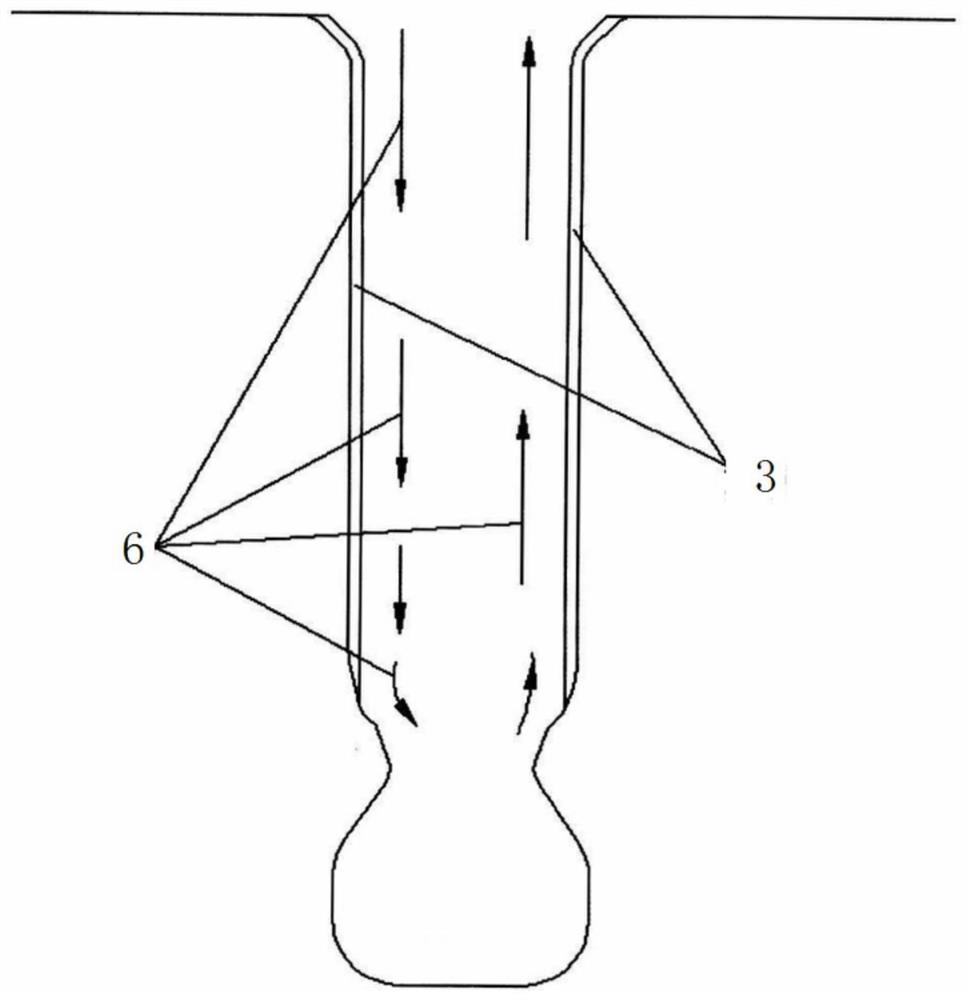

[0022] Step 1: Use the progressive broaching method on the CNC broaching machine to rough the square groove, expand the groove, and form the rough broaching process of the tenon and groove 1 groove shape layer by layer with a broach;

[0023] Step 2: Replace the finishing broach to remove the remainder of the tenon and groove 1 groove, and directly process the part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com