Height-adjustable vegetable planting rack

A planting frame, adjustable technology, applied in botany equipment and methods, container cultivation, gardening, etc., can solve the problem of not having adjustable height, achieve the effect of facilitating the planting process, convenient use process, and promoting growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

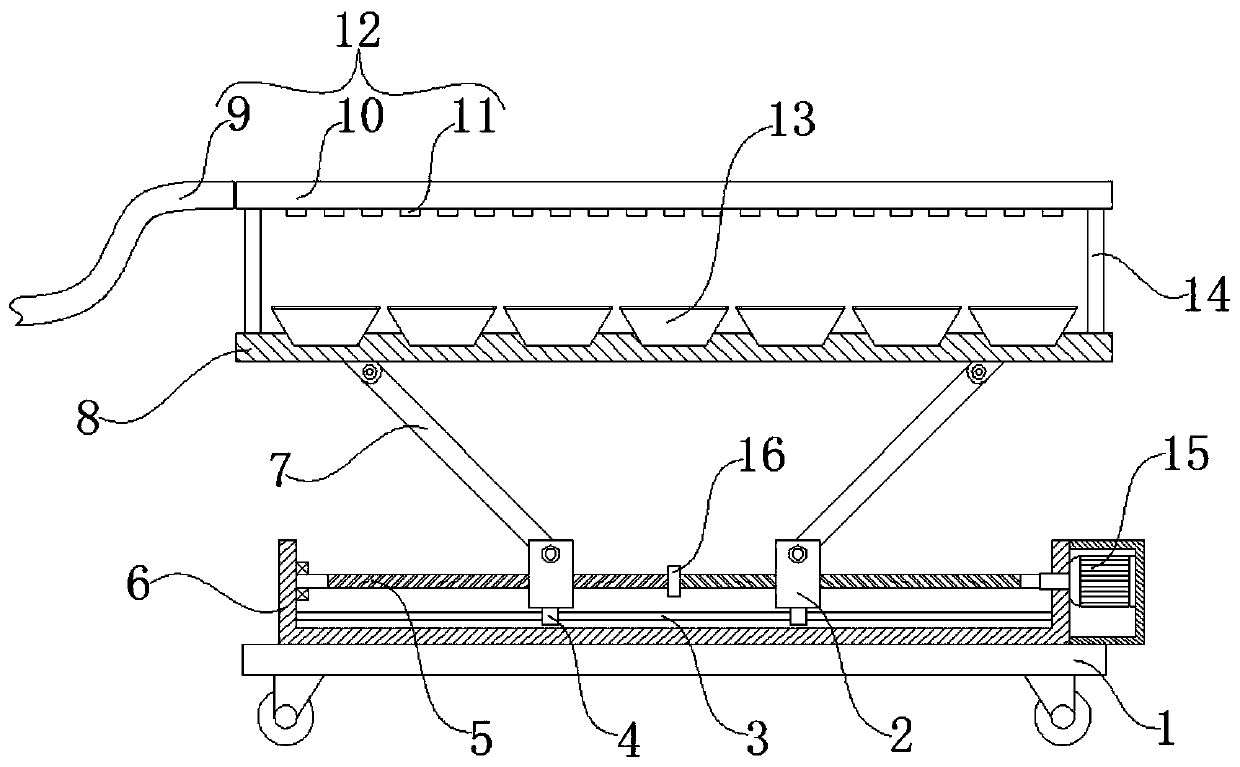

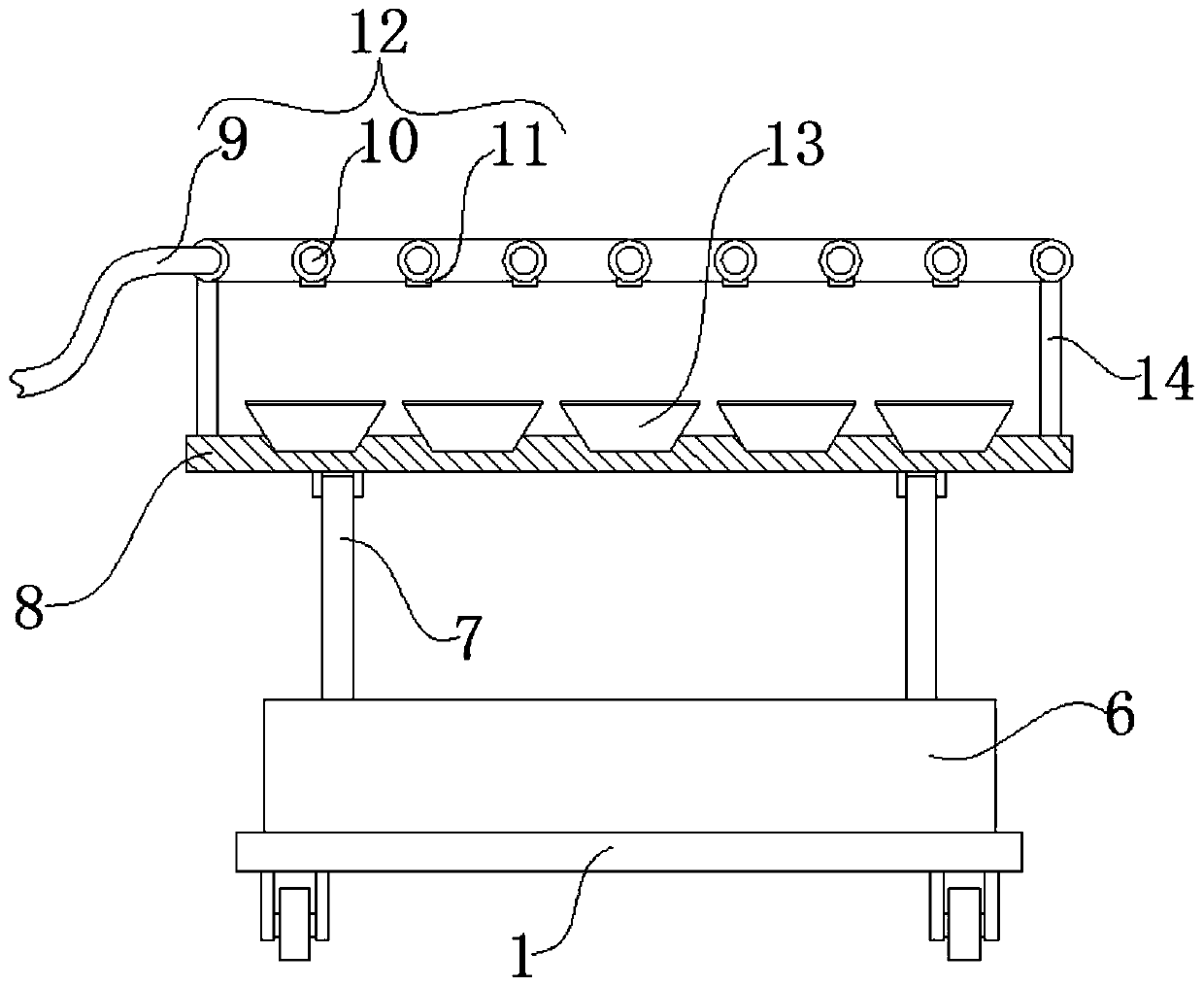

[0020] refer to Figure 1-3 , a height-adjustable vegetable planting rack, comprising a bottom plate 1, a box body 6 is fixedly connected to the upper surface of the bottom plate 1, and a motor 15 is fixedly connected to one side of the box body 6, and the motor 15 is connected to an external battery pack through a wire, and the wire A switch for controlling the operation of the motor 15 is fixedly connected to the top. The motor 15 is specifically a servo motor. The model of the motor 15 is YL90L-4-1.5KW. One end of the output shaft of the motor 15 runs through the box body 6 and is rotatably connected with a bidirectional screw 5. And one end of the two-way screw 5 is rotatably connected to the other side of the inner wall of the box body 6 through a bearing, the two sides of the outer surface of the two-way screw 5 are threadedly connected with the moving block 2 respectively, and one side of the outer surface of the two-way screw 5 is provided with a forward thread structu...

Embodiment 2

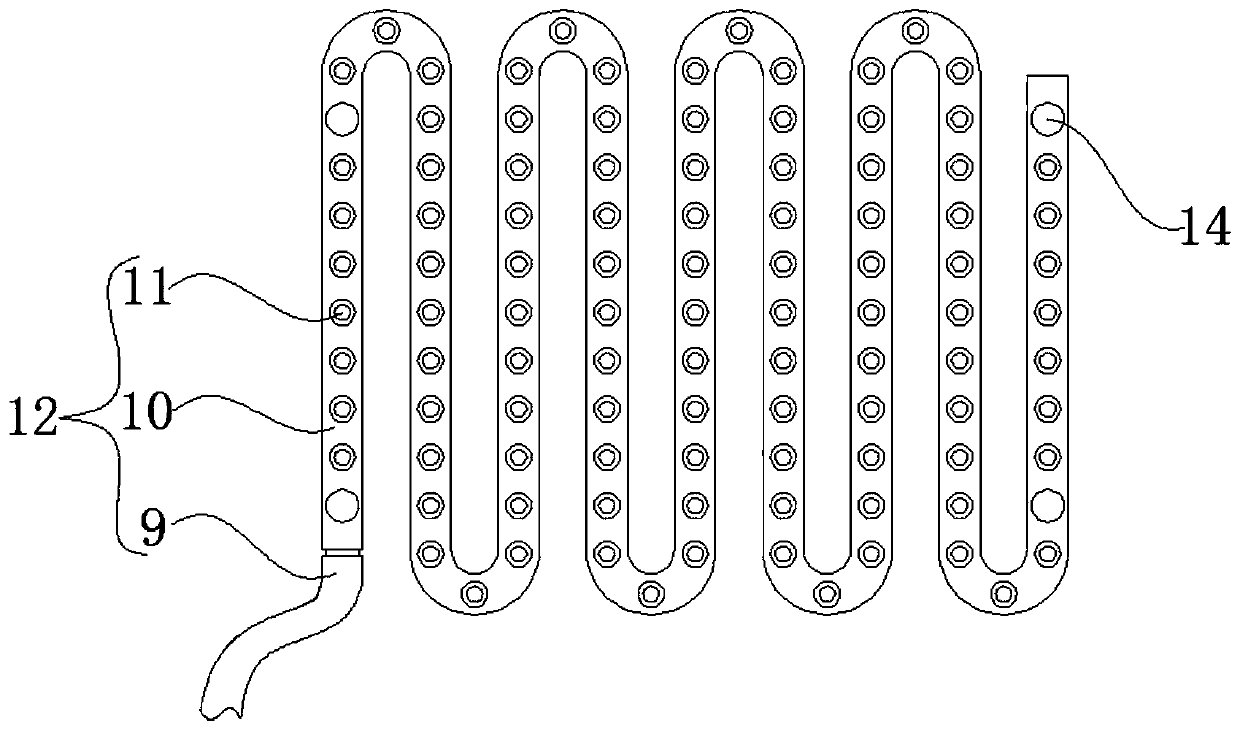

[0025] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the humidifying mechanism 12 includes a connecting pipe 10, which is fixedly connected to the upper ends of four installation rods 14, and the connecting pipe 10 is U-shaped coiled Installed on the four installation rods 14, one end of the connecting pipe 10 is fixedly connected with an air delivery pipe 9, the air delivery pipe 9 is a flexible hose structure, and the lower end of the connecting pipe 10 is evenly and fixedly connected with a plurality of high-pressure nozzles 11, and a plurality of The high-pressure nozzle 11 is located directly above the multiple planting pots 13, and the gas delivery pipe 9 is externally connected with a humidification device. Through the humidification device, the humidified gas can be delivered to the connecting pipe 10 through the gas delivery pipe 9, and then the humidified gas will be fully supplied from the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com