Nut opening size detection and classification device

A size detection and classification device technology, applied in the direction of measuring devices, optical devices, sorting, etc., can solve the problems of inconvenient direct detection of the size of nut openings with the naked eye, and achieve the goal of ensuring the quality of image collection, suitable for popularization and application, and improving detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

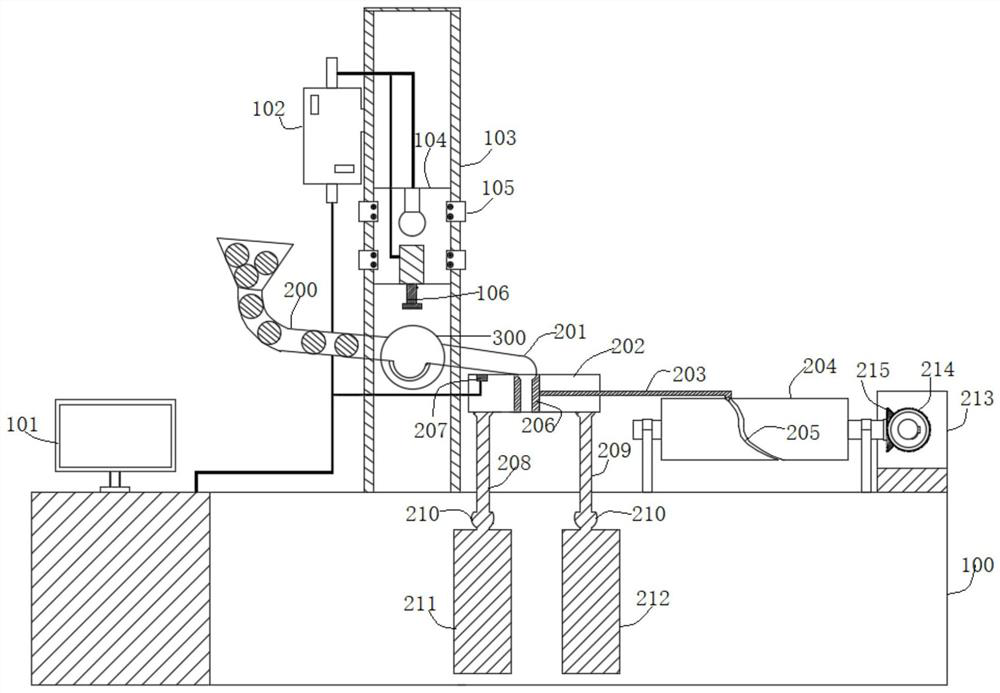

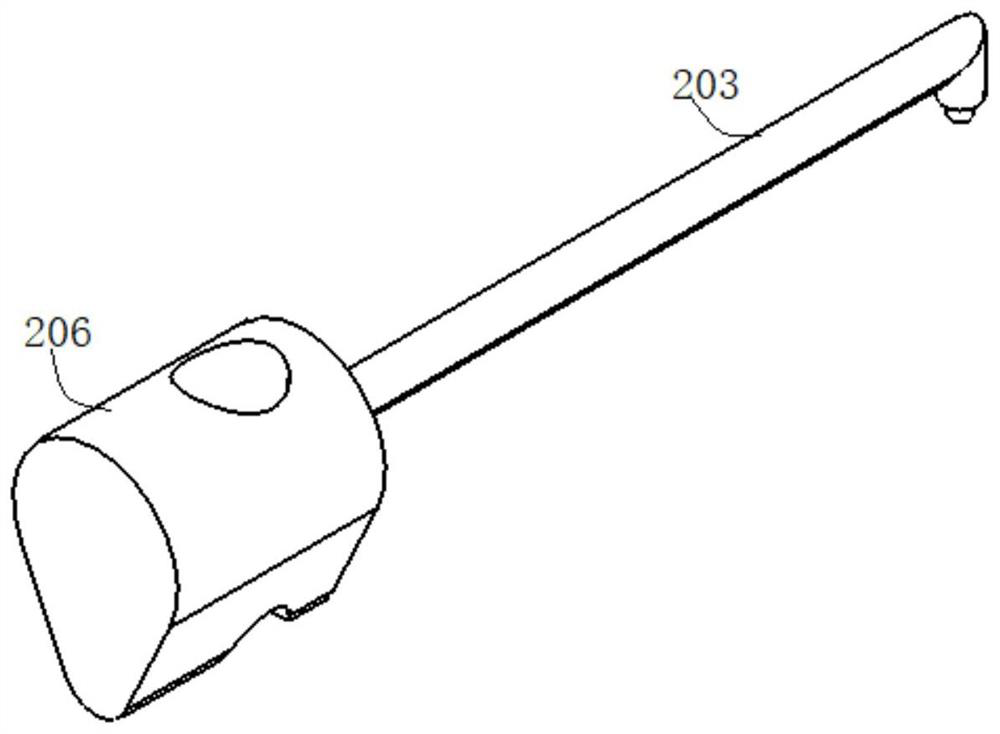

[0036] Such as Figure 1-Figure 4 As shown, a kind of nut opening size detection and classification device of the present embodiment includes a base 100, on which a detection unit and a sorting unit are arranged, wherein the detection unit includes a CCD camera 106 arranged above the feeding pipeline 200; The outlet end of the material pipeline 200 is provided with a discharge pipeline 201, and the sorting unit includes a sorting passage 202 located below the outlet of the discharge pipeline 201, and both sides of the bottom of the sorting passage 202 are correspondingly provided with high-quality product storage boxes 211 and defective products. The storage box 212 is slidingly fitted with a sliding guide rod 203 in the sorting channel 202. The sliding guide rod 203 is connected with the power drive assembly and driven by it to slide in the sorting channel 202. The front end of the sliding guide rod 203 is provided with a sorting Cylinder 206, a blanking cavity is opened in t...

Embodiment 2

[0042] A nut opening size detection and classification device in this embodiment is basically the same as in Embodiment 1. Further, the detection unit in this embodiment also includes a camera adjustment assembly, and the camera adjustment assembly includes a guide column 103 arranged on the base 100, And corresponding to the sliding block 104 matched with the guiding post 103 , the sliding block 104 is locked on the guiding post 103 through the locking block 105 , and the CCD camera 106 is installed on the sliding block 104 . Specifically, the base 100 is provided with two guide columns 103 distributed in parallel, and the two sides of the slider 104 are provided with locking blocks 105 respectively. The locking block 105 is locked on the guide column 103 so as to realize the flexible movement and fast fixing of the slider 104 on the guide column 103 . An illumination element is also provided above the CCD camera 106 .

[0043] This embodiment can effectively adjust the heig...

Embodiment 3

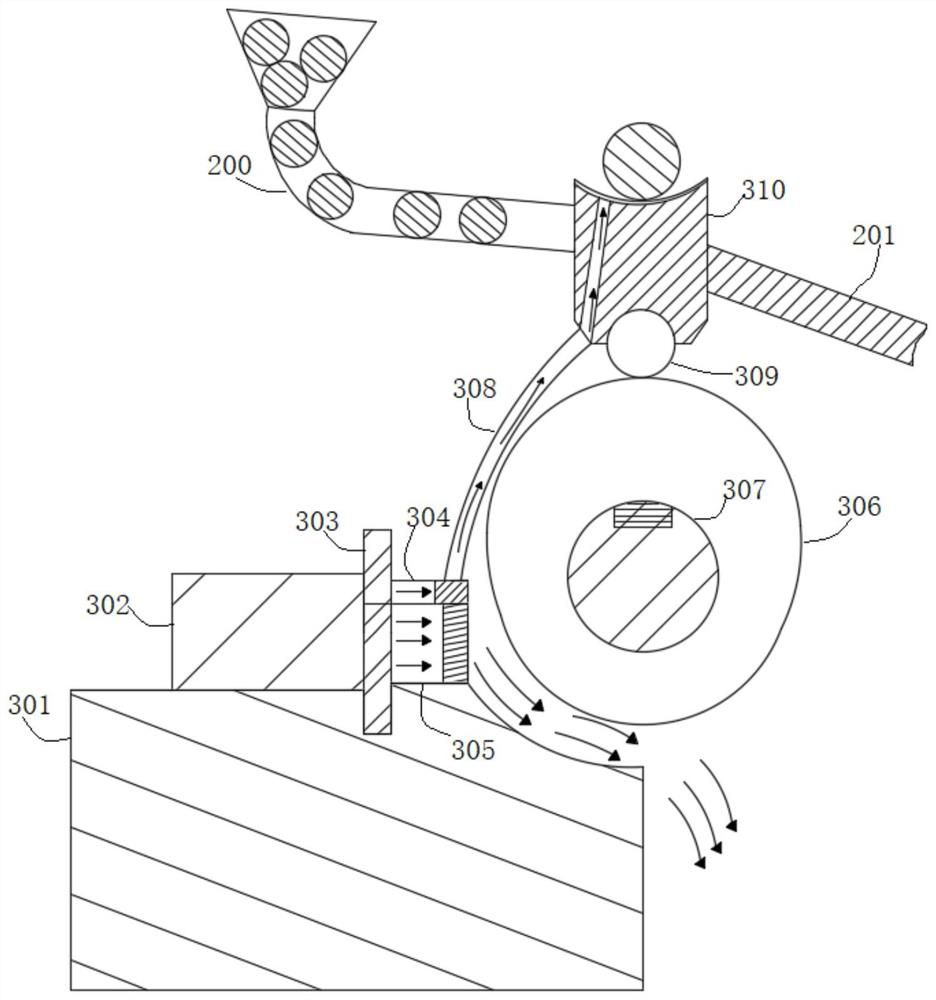

[0045] A nut opening size detection and classification device of this embodiment is basically the same as the above embodiment, the difference is that a pose transformation unit 300 is also provided between the feed pipeline 200 and the discharge pipeline 201 in this embodiment, such as figure 2 As shown, the pose transformation unit 300 includes a push rod seat 310 for receiving nuts, the push rod seat 310 is located directly below the CCD camera 106, and the push rod seat 310 is slidably mounted on the longitudinal guide rail of the base 100, and can be moved along the Slide up and down in the direction of the guide rail; an eccentric lifting cam 306 is provided under the push rod seat 310 to drive it to slide up and down, the bottom of the push rod seat 310 is in contact with the surface of the lifting cam 306 through the roller 309, and a blower is provided on one side of the lifting cam 306 302, the blower 302 is connected with the blast chamber 303, and the blast chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com