Holder device for automobile fixtures

A technology of card holders and inspection tools, which is applied in the direction of adopting mechanical devices, measuring devices, mechanical measuring devices, etc., can solve problems such as relatively difficult, complex structure of inspection tools, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0024] Example.

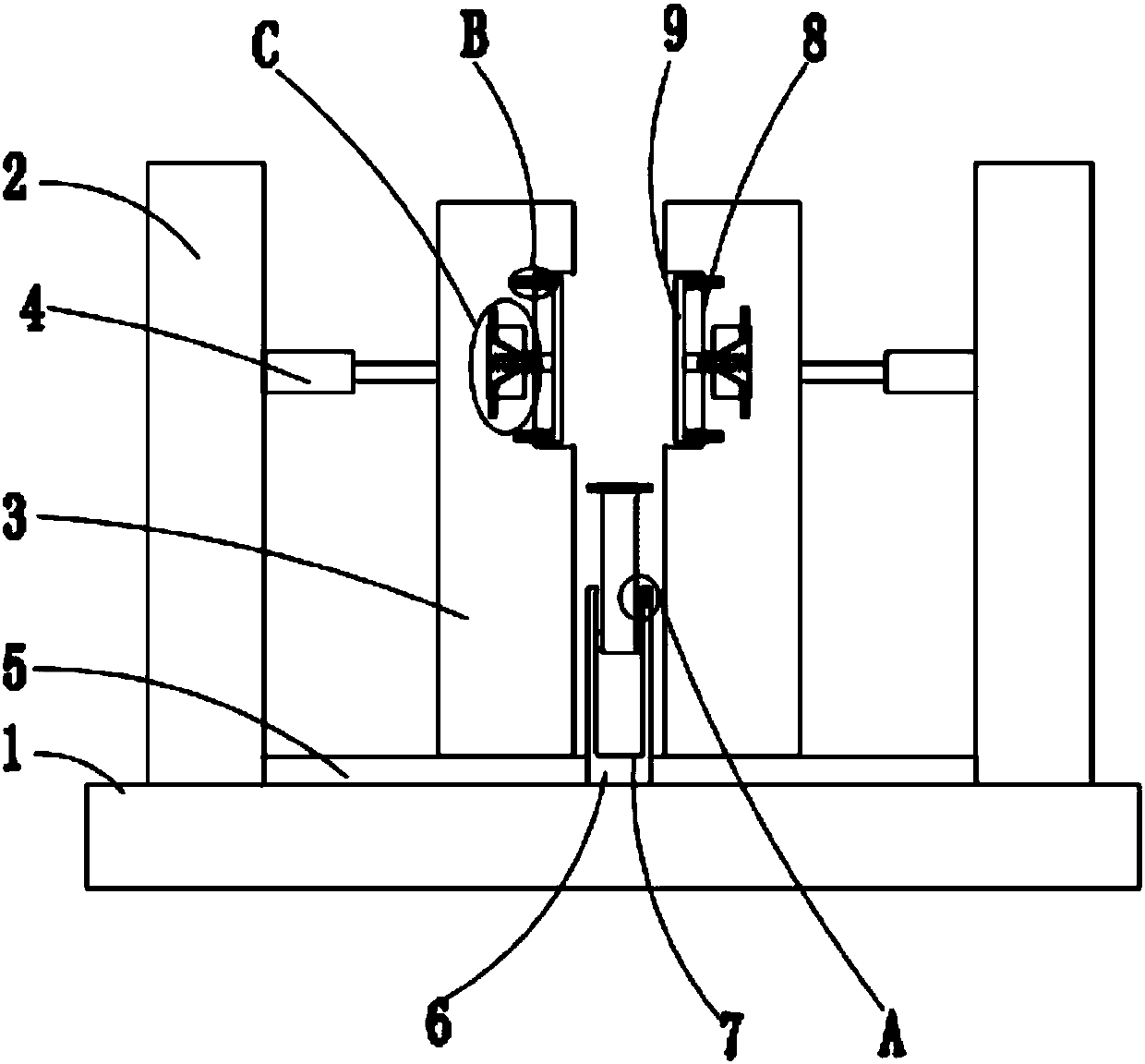

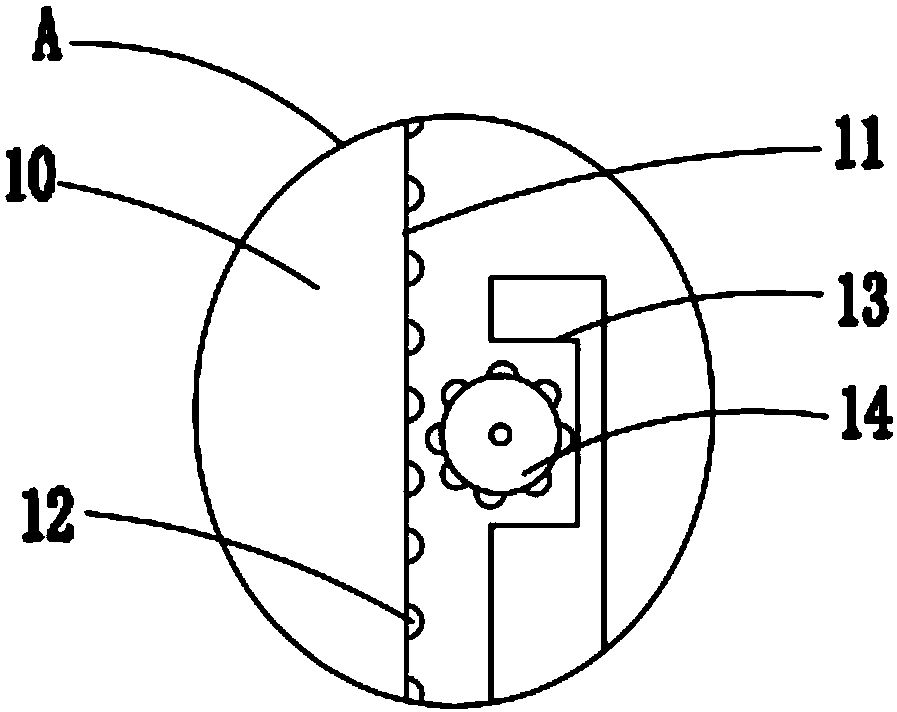

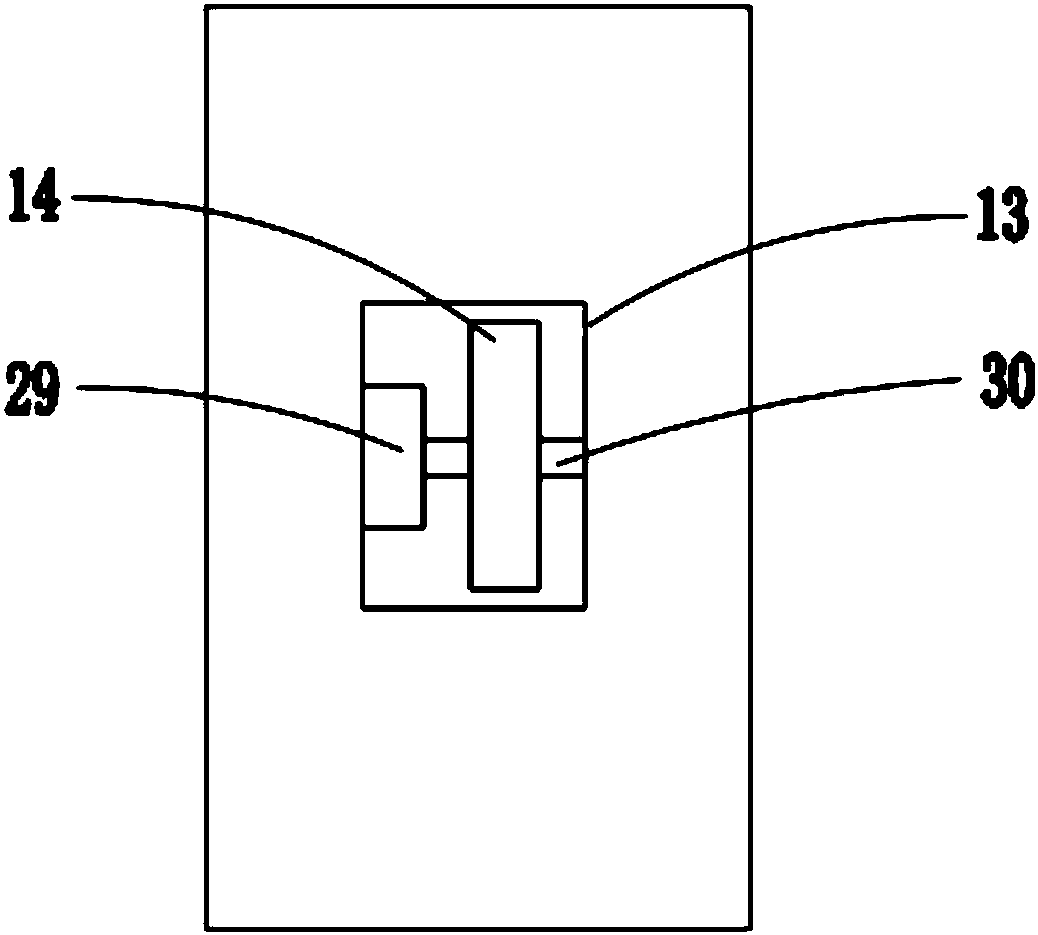

[0025] refer to Figure 1-6 , a card seat device used for automobile inspection tools, including a base 1, two support columns 2 are fixedly installed on the top side of the base 1, two card seat bodies 3 are arranged between the two support columns 2, and the base 1 Two slide rails 5 are fixedly installed on the top side, and the two card holder bodies 3 are slidably installed on the two slide rails 5 respectively, and a cylinder 4 is fixedly installed on the sides of the two support columns 2 close to each other, and the two cylinders 4 The output shafts are respectively fixedly installed on the sides of the two card holder bodies 3 away from eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com