Joint clamping buckle for tractive rigging of intelligent equipment

A technology for pulling rigging and intelligent equipment, applied in the field of wear-resistant buckles and node buckles, it can solve the problems of affecting the transmission accuracy and strength, wear and contact points of the chain, and long replacement time, so as to improve the service life and fast installation. Replacement, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

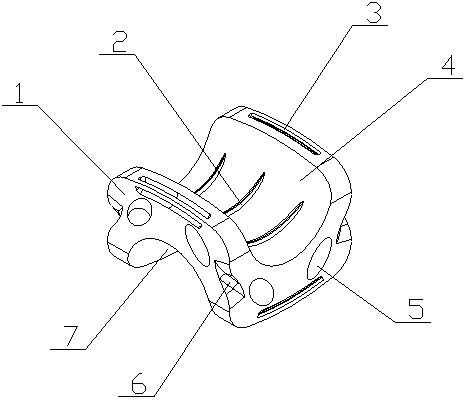

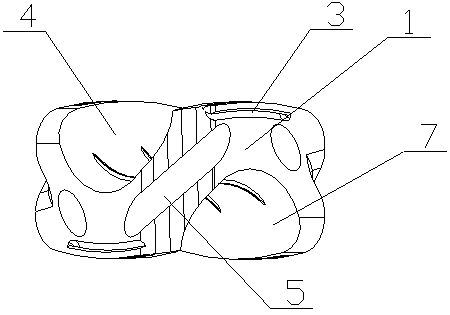

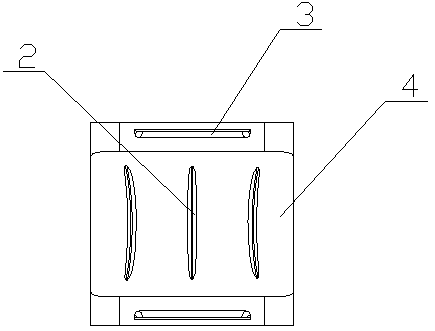

[0017] The node buckle used in the smart device pulling rigging of the present invention is realized in this way, consisting of the main body buckle (1), the friction strip (2), the fixed pull groove (3), the upper clamp groove (4), the buffer hole (5 ), bending slot (6), lower card slot (7), lower ring (8) and upper ring (9), the upper side of the main buckle (1) has an arc-shaped upper card slot (4) , the lower side of the main body buckle (1) is provided with an arc-shaped lower slot (7), the central axis of the upper slot (4) is perpendicular to the central axis of the lower slot (7), and the upper A plurality of friction strips (2) are equidistantly arranged on the groove wall of the card slot (4), and the friction strips (2) extend along the arc direction of the upper card slot (4), and the lower card slot (7) A plurality of friction strips (2) are equidistantly arranged on the groove wall, and the friction strips (2) extend along the arc direction of the lower card slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com