Cleaning wiper for glass

A glass and cleaning cloth technology, applied in the field of cleaning cloth, can solve problems such as difficult cleaning and high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

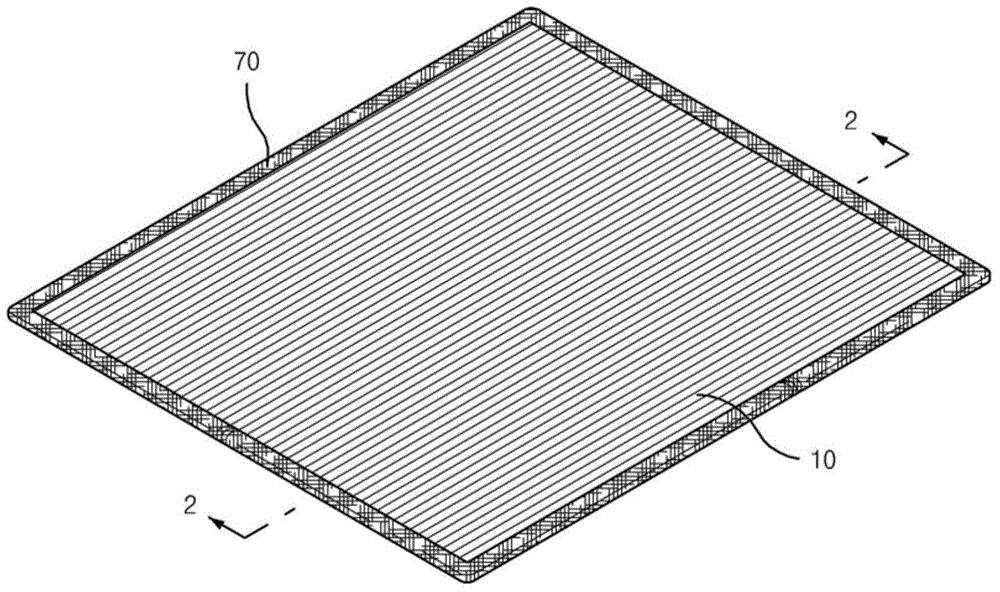

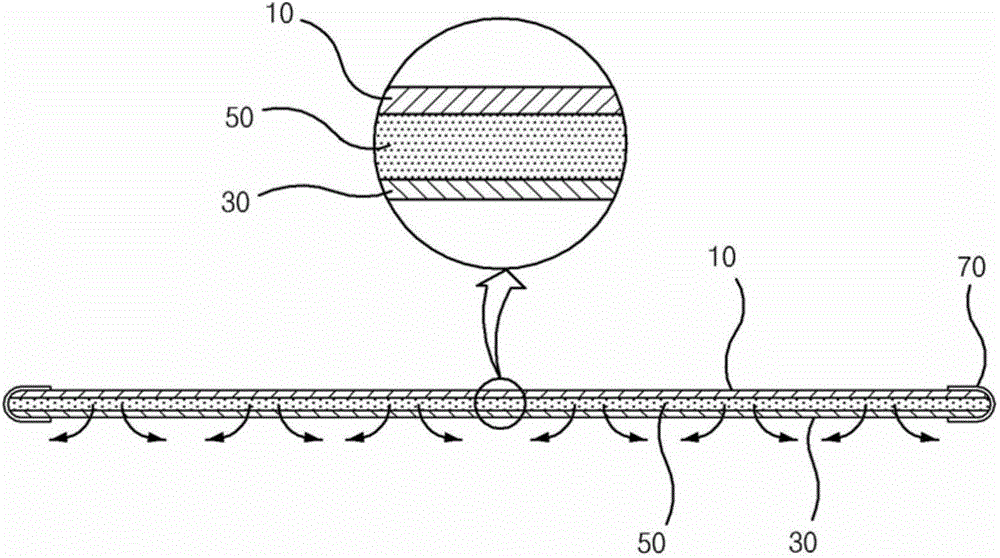

[0026] figure 1 To show a perspective view of a glass cleaning cloth of a preferred exemplary embodiment of the present invention, figure 2 for along figure 1 Cross-sectional view of midline 2-2.

[0027] Such as Figure 1 to Figure 2 As shown, the glass cleaning cloth of the exemplary embodiment of the present invention includes: a first microfiber cloth 10; a second microfiber cloth 30; The middle layer 50 in between.

[0028] It is particularly advantageous that the first microfiber cloth 10 and the second microfiber cloth 30 are warp knitted fabrics woven with single warp conjugated yarns made of polyester and nylon.

[0029] Since the warp knitted fabric is woven with rows of warp yarns having an uneven surface, air is allowed to minutely flow between the middle layer 50 and the outside.

[0030] Although any elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com