Heavy-current crowned spring jack

A high-current, crown spring technology, applied in the direction of circuits, electrical components, contact parts, etc., can solve the problems of small clamping force of the crown spring socket, arcing, pin loosening, etc., to enhance the clamping force, increase Insertion life, not easy to loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

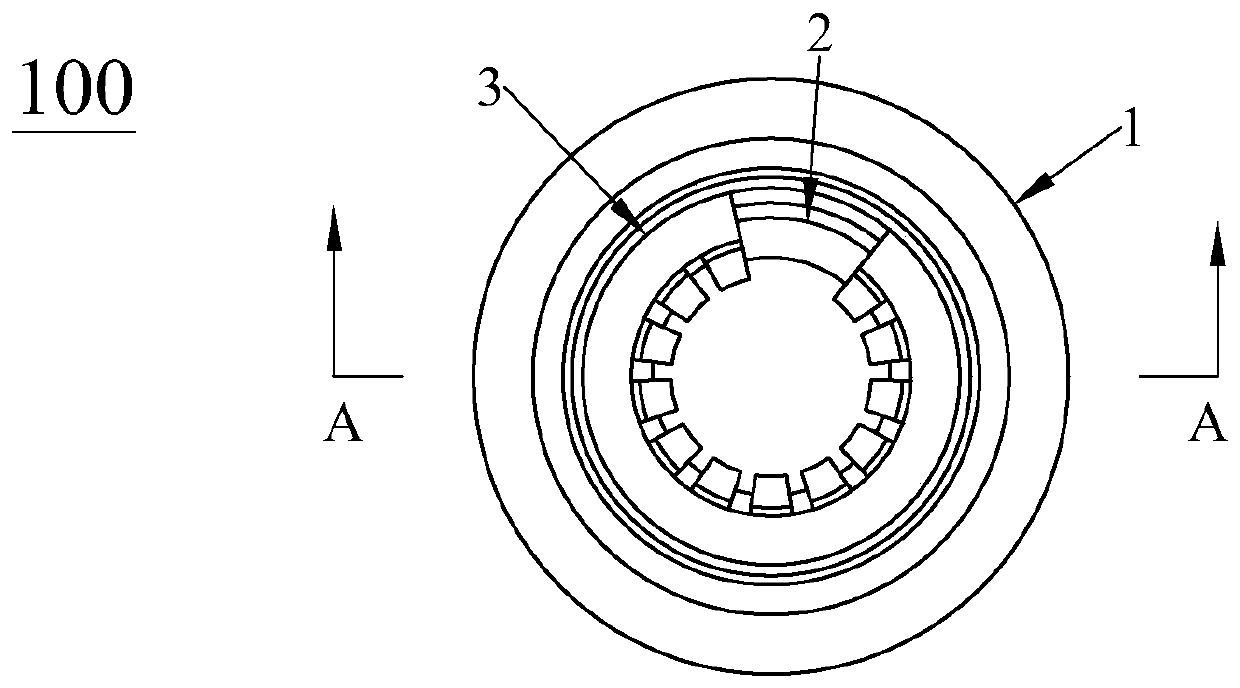

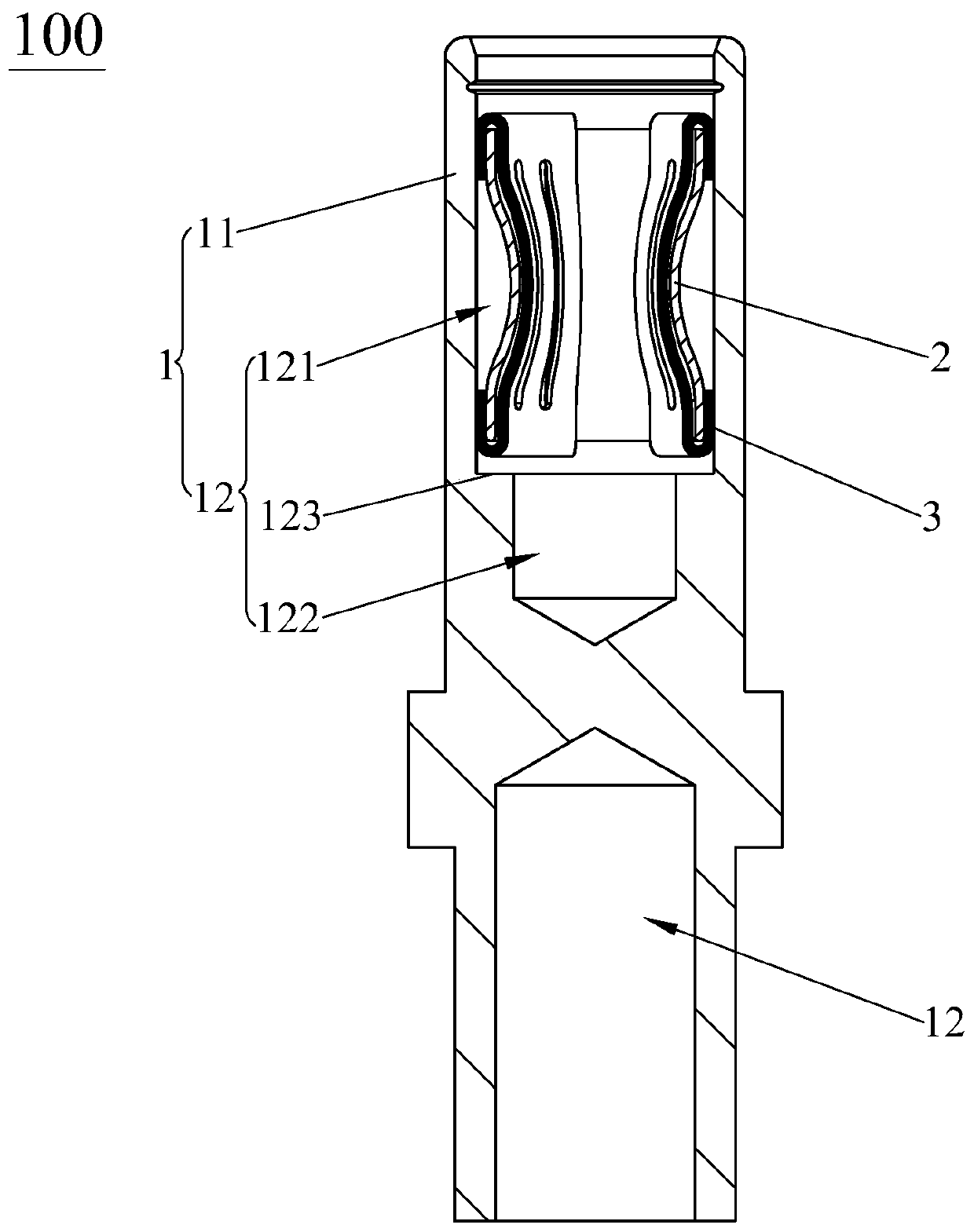

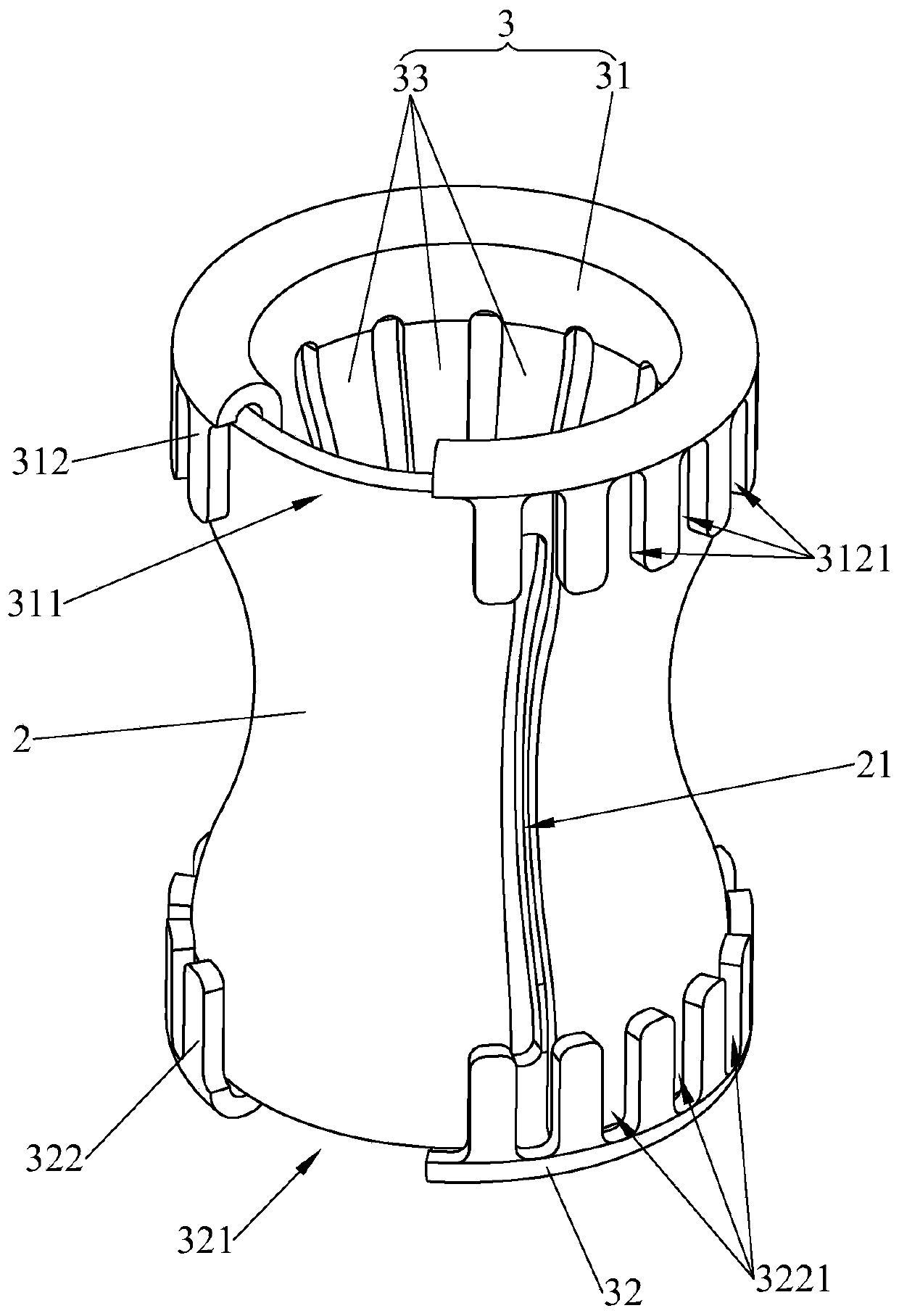

[0023] see Figure 1 to Figure 4 , The high-current crown spring socket 100 of the present invention includes an outer cylinder 1 , an inner cylinder 2 and a crown spring 3 sequentially from outside to inside. The crown spring 3 includes a front end ring 31, a rear end ring 32 and a reed 33 connected between the front end ring 31 and the rear end ring 32. The front end ring 31 and the rear end ring 32 are each provided with a fracture that makes the head and tail are disconnected. 311, 321, by means of the fractures 311, 321, the crown spring 3 is easily deformed, so that it is convenient to install into the inner cylinder 2. The fracture 311 of the front end ring 31 and the fracture 321 of the rear end ring 32 are arranged opposite to each other, which is condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com