Heat exchanger fin, heat exchanger, indoor unit and air conditioner

A technology of heat exchangers and fins, which is applied in the field of air conditioners, can solve the problems of affecting the heat exchange efficiency of air conditioners, low utilization rate of heat exchangers, and excess air volume, so as to improve utilization rate, save energy consumption, and reduce waste of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

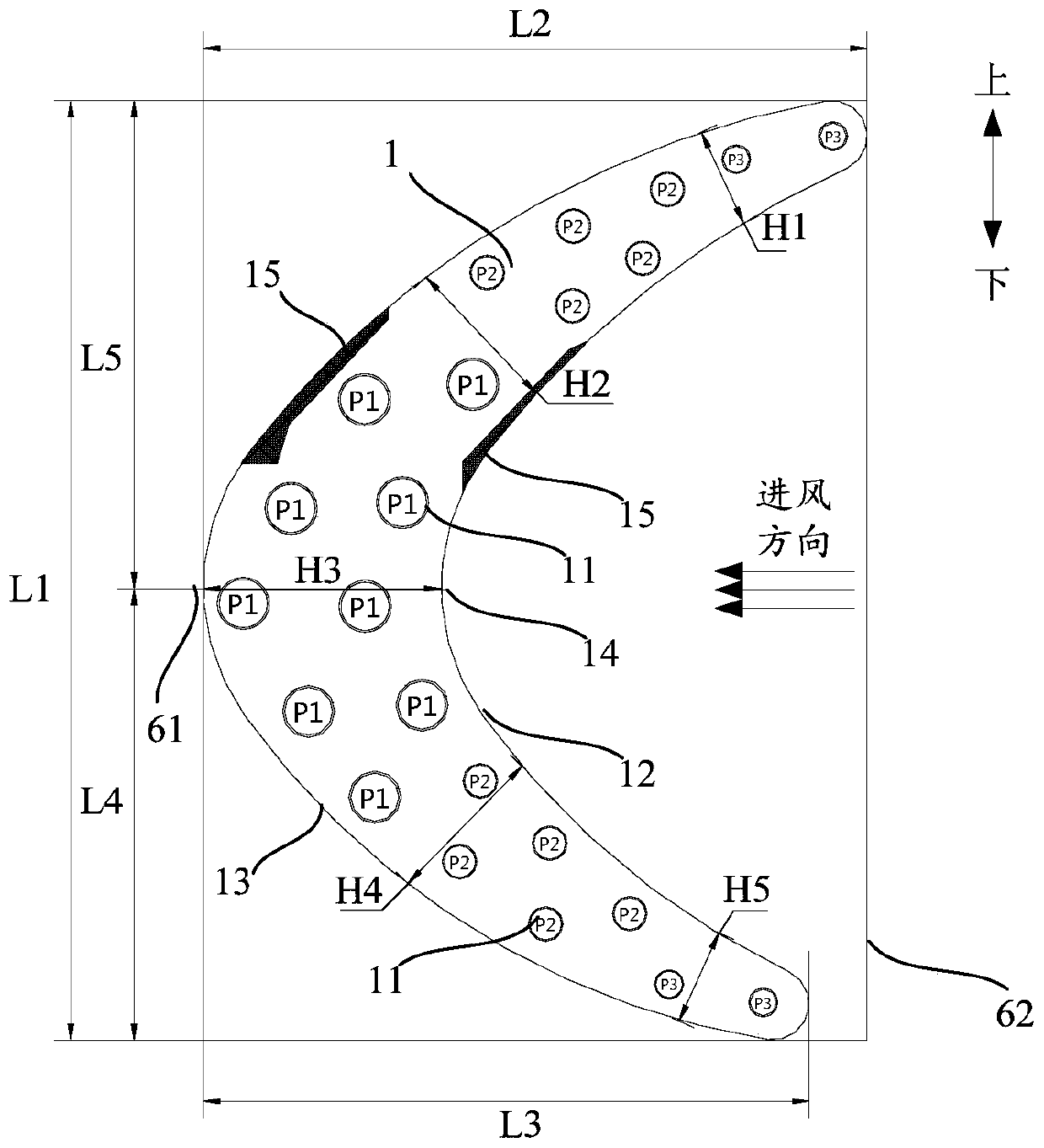

[0064] A heat exchanger fin is provided in this embodiment, such as figure 1 As shown, it includes an integrally formed fin body 1, the fin body 1 includes an air outlet contour 13 on one side and an air inlet contour 12 on the opposite side, and the fin body 1 is provided with A plurality of refrigerant pipe installation holes 11 for installing refrigerant pipes. The fin body 1 is concave along the direction from the air inlet side to the air outlet side, forming a curved shape, on the straight line where the radius of curvature of the air outlet contour line 13 of the fin body 1 is located, or on the air inlet contour line 12 of the fin body 1 On the straight line where the curvature radius of , the distance between the air inlet contour line 12 and the air outlet contour line 13 of the fin body 1 gradually decreases from the middle of the heat exchanger fin to both ends. Correspondingly, the refrigerant pipe installation hole 11 The inner diameter of the heat exchanger fin...

Embodiment 2

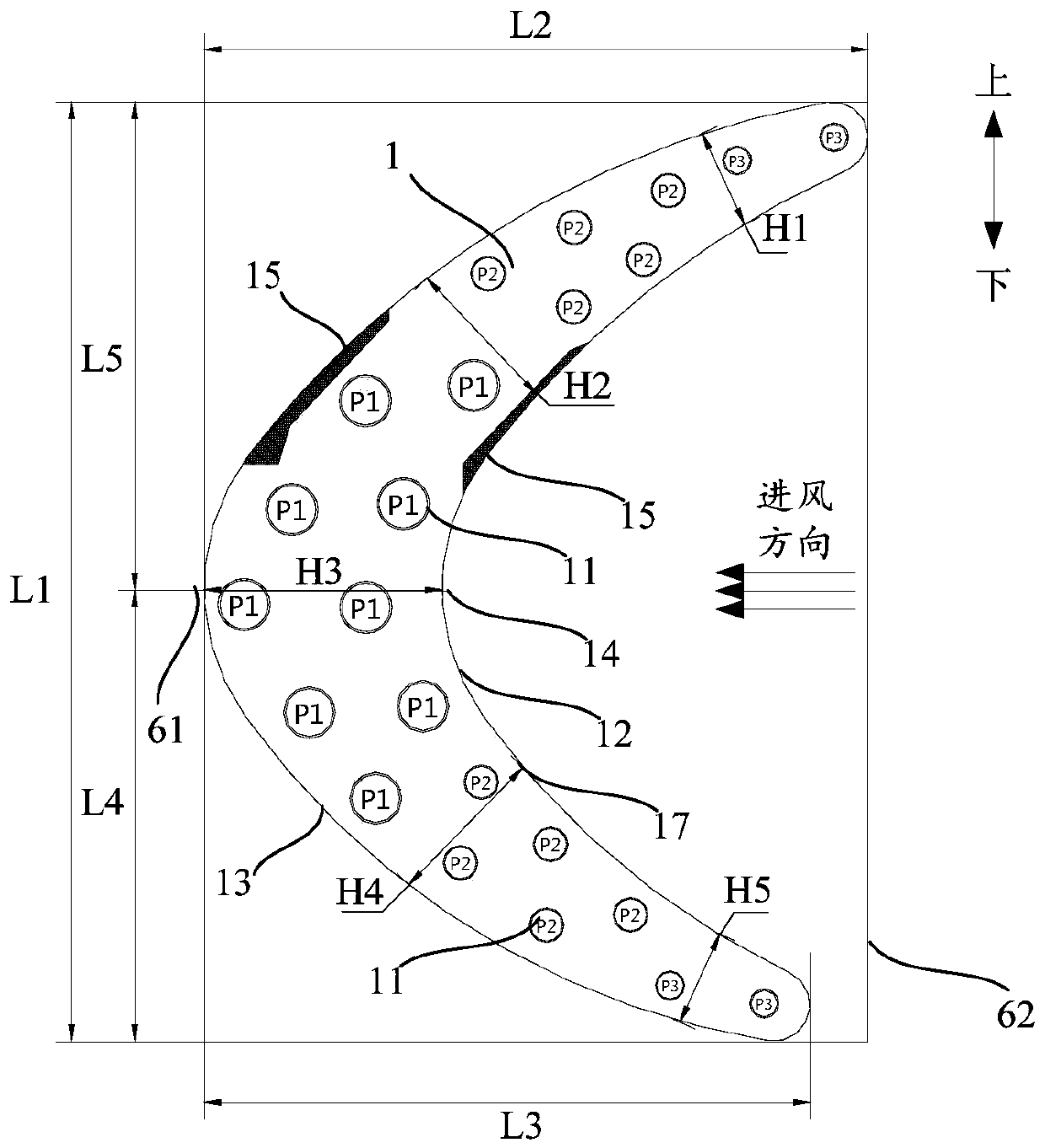

[0066] A heat exchanger fin is provided in this embodiment, such as figure 2As shown, it includes an integrally formed fin body 1, the fin body 1 includes an air outlet contour 13 on one side and an air inlet contour 12 on the opposite side, and the fin body 1 is provided with A plurality of refrigerant pipe installation holes 11 for installing refrigerant pipes. The fin body 1 is concave along the direction from the air inlet side to the air outlet side, forming a curved shape, on the straight line where the radius of curvature of the air outlet contour line 13 of the fin body 1 is located, or on the air inlet contour line 12 of the fin body 1 On the straight line where the curvature radius of , the distance between the air inlet contour line 12 and the air outlet contour line 13 of the fin body 1 gradually decreases from the middle of the heat exchanger fin to both ends. Correspondingly, the refrigerant pipe installation hole 11 The inner diameter of the heat exchanger fin...

Embodiment 3

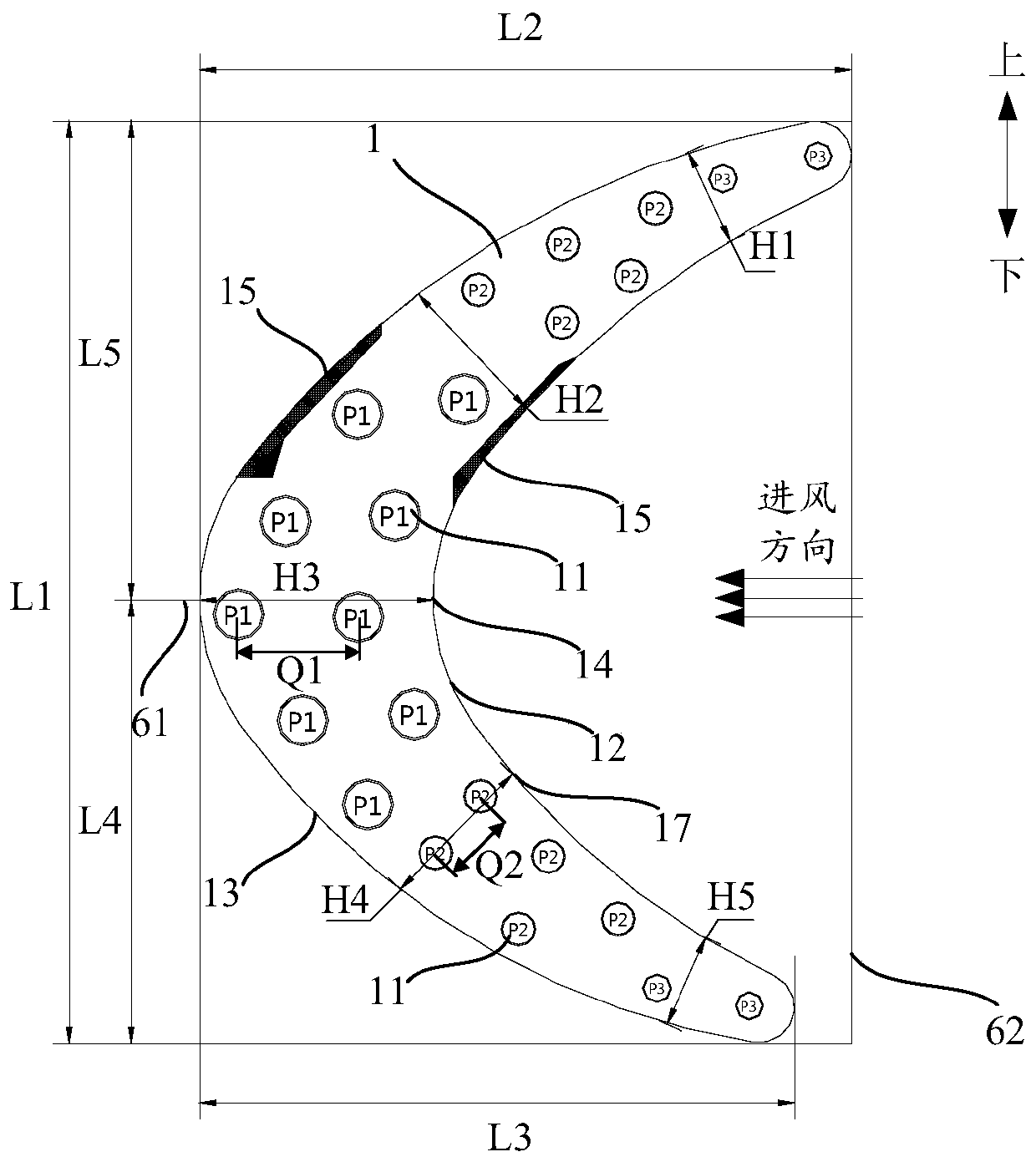

[0068] A heat exchanger fin is provided in this embodiment, such as image 3 As shown, it includes an integrally formed fin body 1, the fin body 1 includes an air outlet contour 13 on one side and an air inlet contour 12 on the opposite side, and the fin body 1 is provided with A plurality of refrigerant pipe installation holes 11 for installing refrigerant pipes. The fin body 1 is concave along the direction from the air inlet side to the air outlet side, forming a curved shape, on the straight line where the radius of curvature of the air outlet contour line 13 of the fin body 1 is located, or on the air inlet contour line 12 of the fin body 1 On the straight line where the curvature radius of , the distance between the air inlet contour line 12 and the air outlet contour line 13 of the fin body 1 gradually decreases from the middle of the heat exchanger fin to both ends. Correspondingly, the refrigerant pipe installation hole 11 The inner diameter of the heat exchanger fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com