In-situ composite ceramic diaphragm with core-shell structure and preparation method and application thereof

A technology of core-shell structure and ceramic diaphragm, applied in structural parts, nanotechnology for materials and surface science, repair/maintenance of secondary batteries, etc., can solve the problems of light and thin batteries, high energy density, harshness, instability, etc. , to achieve good thermal closed cell performance, improve safety, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

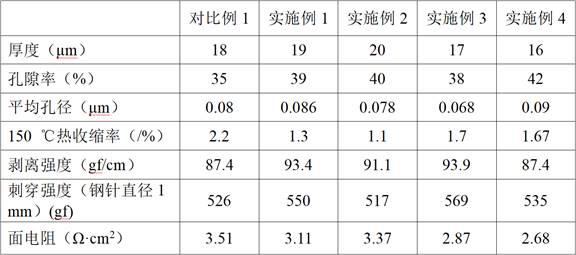

Embodiment 1

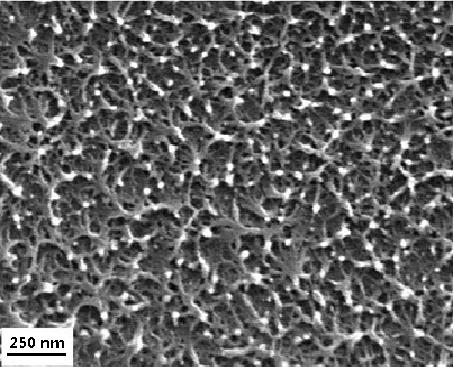

[0027] The in-situ composite ceramic separator with the core-shell structure was prepared by the following steps:

[0028](1) Take 30g of nano-ceramic particles with a particle size of 30-100nm, 2g of γ-aminopropyltriethoxysilane, 8g of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, and 20g of ethyl acrylate , 40g of styrene, 40g of methyl methacrylate, and 1g of azobisisobutyronitrile are proportioned, using γ-aminopropyltriethoxysilane and isopropyltris (dioctyl pyrophosphate acyloxy) After the nano-ceramic particles are modified by titanate, they are dispersed in a coating agent prepared by ethyl acrylate, styrene and methyl methacrylate, and azobisisobutyronitrile is added for in-situ polymerization to prepare and screen out a particle size of 100. -350nm core-shell structure nano-ceramic particles;

[0029] (2) 50g of nano-ceramic particles with core-shell structure, 100g of diisononyl phthalate, 100g of dioctyl azelaic acid, 10g of low density polyethylene (vis...

Embodiment 2

[0033] Take 40g of nano-ceramic particles with a particle size of 30-100nm, 4g of γ-(methacryloyloxy)propyltrimethoxysilane, 8g of isopropyl tris(dioctylpyrophosphate acyloxy)titanate, ethyl acrylate Ester 5g, butyl acrylate 5g, vinyl acetate 2g, acrylamide 2g, acrylic resin 4g, azobisisobutyronitrile 1.2g for proportioning, using γ-(methacryloyloxy)propyltrimethoxysilane A coating agent prepared by dispersing in ethyl acrylate, butyl acrylate, vinyl acetate, acrylamide and acrylic resin after modifying nano-ceramic particles with isopropyl tris(dioctyl pyrophosphate acyloxy) titanate , adding azobisisobutyronitrile in-situ polymerization to prepare and screen out the core-shell structure nano-ceramic particles with a particle size of 100-350nm;

[0034] (2) 40g of nano-ceramic particles with core-shell structure, 100g of di-n-octyl phthalate, 100g of dioctyl azelaate, 100g of (2-ethylhexyl) phthalate, low-density polyethylene ( Viscosity-average molecular weight 100,000) 10 ...

Embodiment 3

[0038] The in-situ composite ceramic separator with the core-shell structure was prepared by the following steps:

[0039] (1) Take 30 g of nano-ceramic particles with a particle size of 30-100 nm, 3 g of γ-glycidyl ether oxypropyltrimethoxysilane, 4 g of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, bis( Dioctyloxy pyrophosphate group) ethylene titanate 3g, butyl acrylate 20g, styrene 50g, vinyl acetate 30g, azobisisoheptanenitrile 1g, azobisisobutyronitrile 1g for proportioning, Nano-ceramic particles were modified by γ-glycidyl ether oxypropyl trimethoxy silane, isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, dispersed in butyl acrylate, styrene, vinyl acetate In the coating agent prepared by the ester, azobisisoheptanenitrile and azobisisobutyronitrile are added for in-situ polymerization to prepare and screen out the core-shell structure nano-ceramic particles with a particle size of 100-350nm;

[0040] (2) 50g of nano-ceramic particles with core-shell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com