Connecting hardware fitting for stepless adjustable sub-conductor phase-to-phase spacer

A technology of interphase spacer rods and connecting fittings, which is applied in the field of overhead transmission lines, can solve problems such as inability to realize stepless adjustment, blind spots in adjustment, hidden dangers in construction safety, etc., and achieve the effects of convenient installation and operation, wide application range and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The wire jumper spacer of the present invention will be further described in detail below in conjunction with the accompanying drawings.

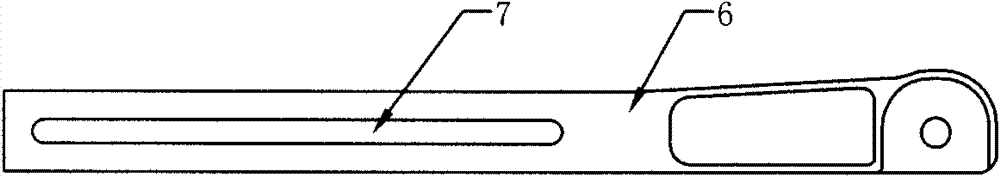

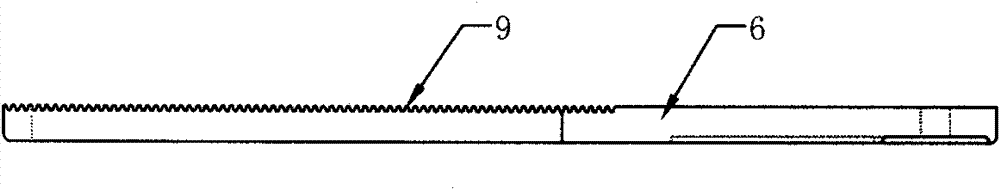

[0027] like figure 1 , 2 As shown, the adjusting plate 16 is a bar-shaped structure, and one side thereof is provided with a rack 9, and the right side of the adjusting plate is provided with a mounting hole for connecting the connecting plate 5, and an elongated adjusting hole 7 is offered on the left side of the adjusting plate. The length of regulating hole 7 is at least the length of 1 / 2 regulating plate 16.

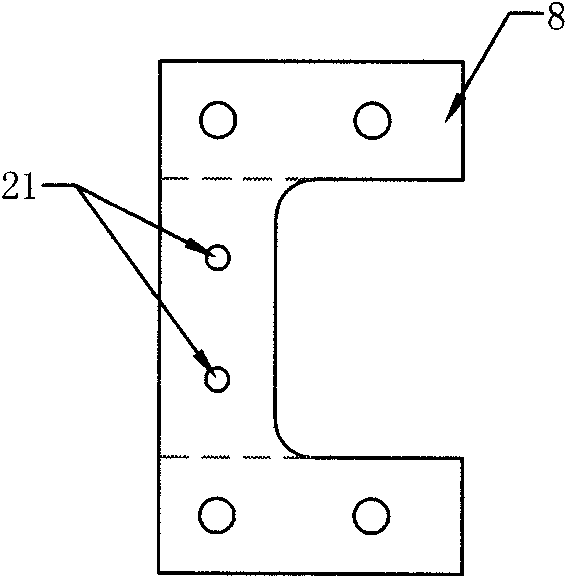

[0028] like Figure 3-5 As shown, the adjustment plate II8 has a flat U-shaped structure, and two racks 9 for engaging with the two adjustment members I6 are symmetrically provided on the surface opposite to the adjustment member I6.

[0029] like Figure 6-8 As shown, the main body of the tensioning device has a flat U-shaped structure, and the lower end of the main body is provided with a hollow boss 18 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com