Pressing-riveting device for bent water pipe, and pressing system

A technology for water pipes and mounting seats, which is applied in the field of curved water pipe riveting devices and their pressing systems, and can solve problems such as complex and diverse installation angles of curved water pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

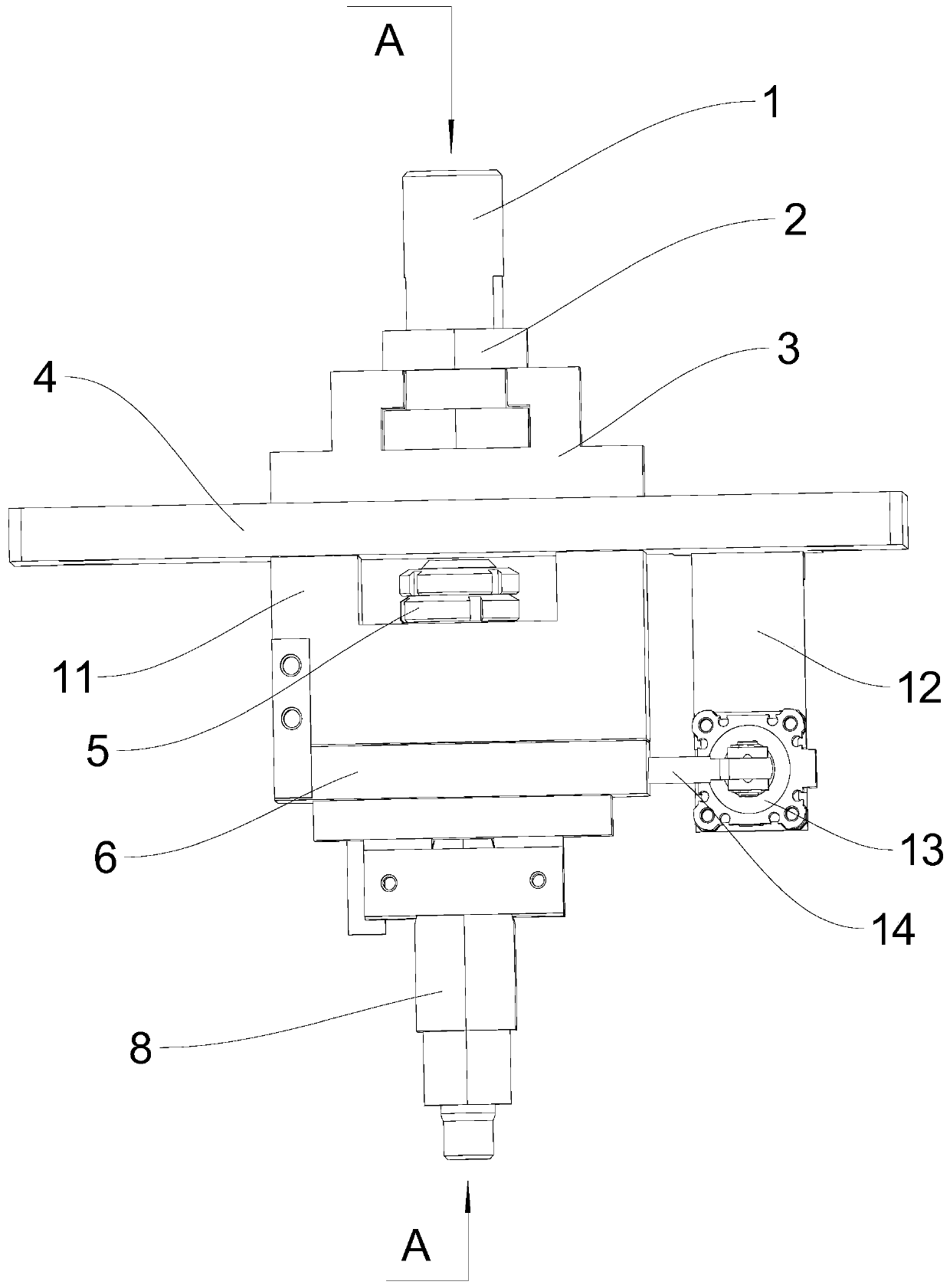

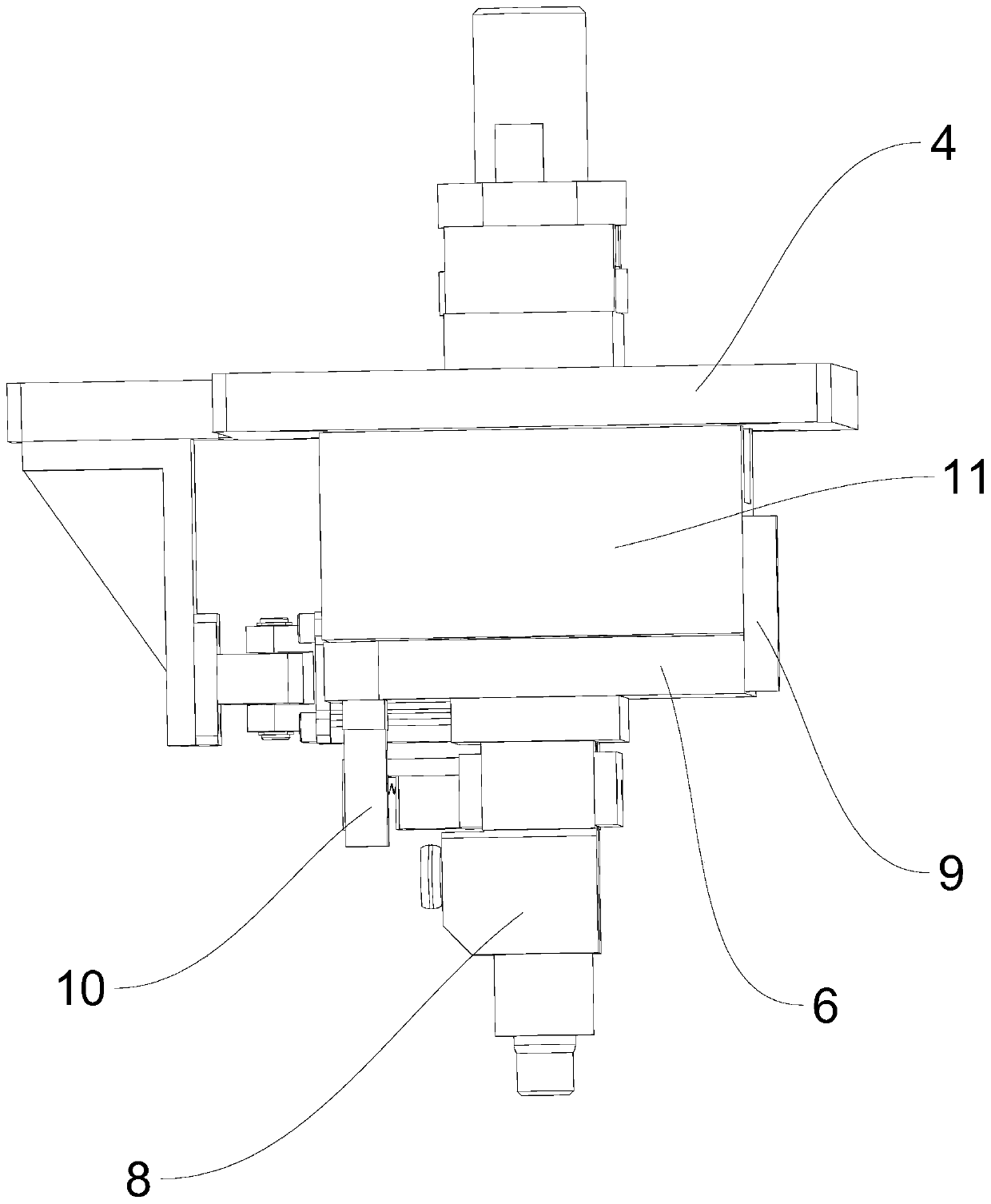

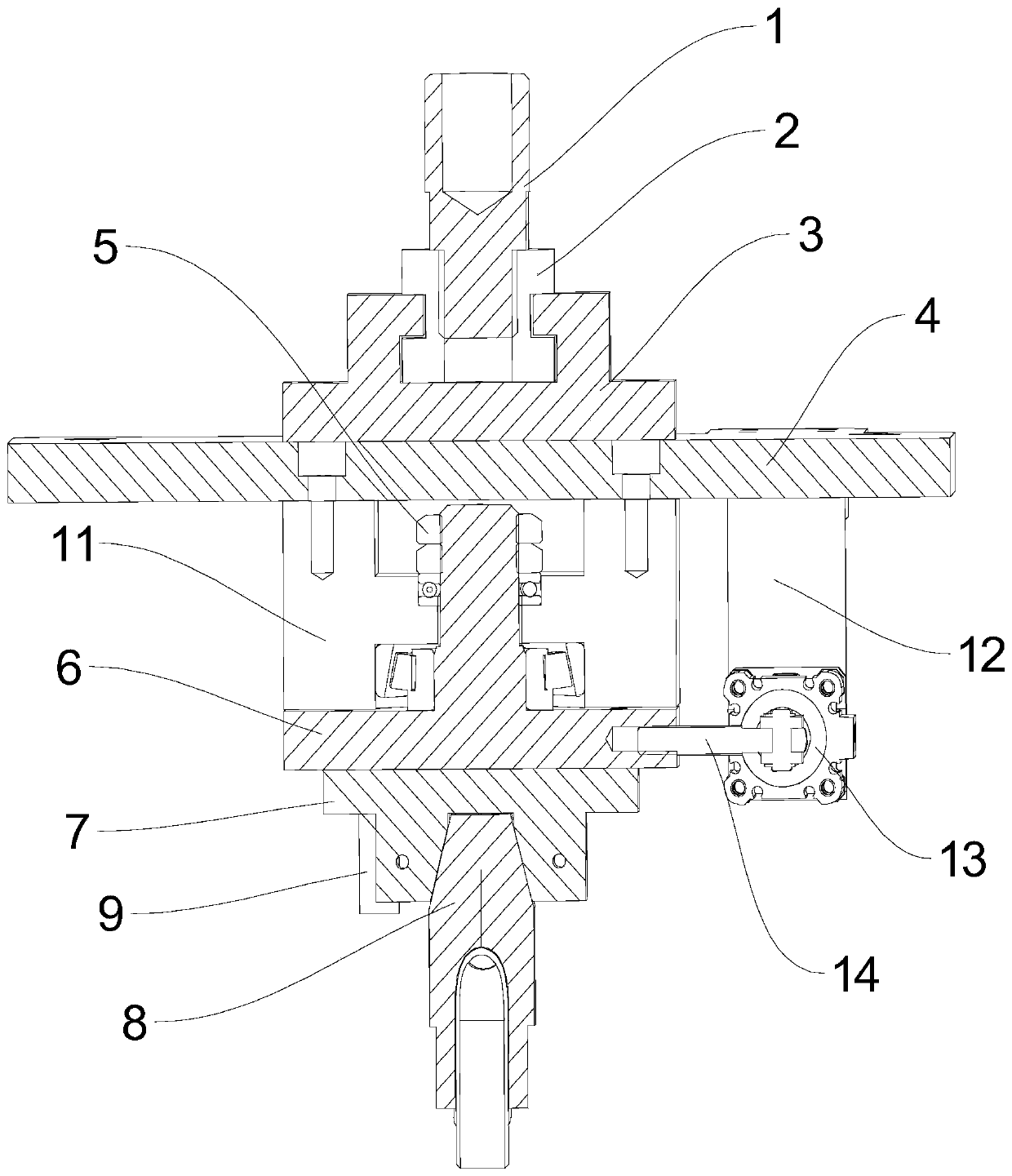

[0030] See Figure 1 to Figure 3 , The elbow pressure riveting device provided in this embodiment includes screw 1, nut 2, connecting block 3, connecting plate 4, stop nut 5, rotating shaft block 6, inclined plane pressing block 7, movable chuck 8, from top to bottom. Limit block 9, photoelectric sensor 10. The limit block 9 is installed on the side wall of the mounting seat, and the plate on the rotating shaft block 6 abuts on the limit block. The photoelectric sensor 10 is arranged at the bottom of the shaft block 6 near the side of the shaft block 6. The elbow pressure riveting device is applied to a pressing system. In addition to the application of the above-mentioned elbow pressure riveting device, the pressing system also includes a cylinder assembly. The cylinder assembly includes a cylinder mounting seat 12, a cylinder 13 and a cylinder connecting head 14. The cylinder mounting base 12 is installed at the lower part of the connecting plate 4, the cylinder 13 is moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com