Planar transformer and power converter

一种平面变压器、电源转换器的技术,应用在变压器领域,能够解决初级绕组工作电压高、PCB层数多、磁芯与绕组绝缘击穿等问题,达到最佳EMI性能、降低成本、减小PCB板层数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

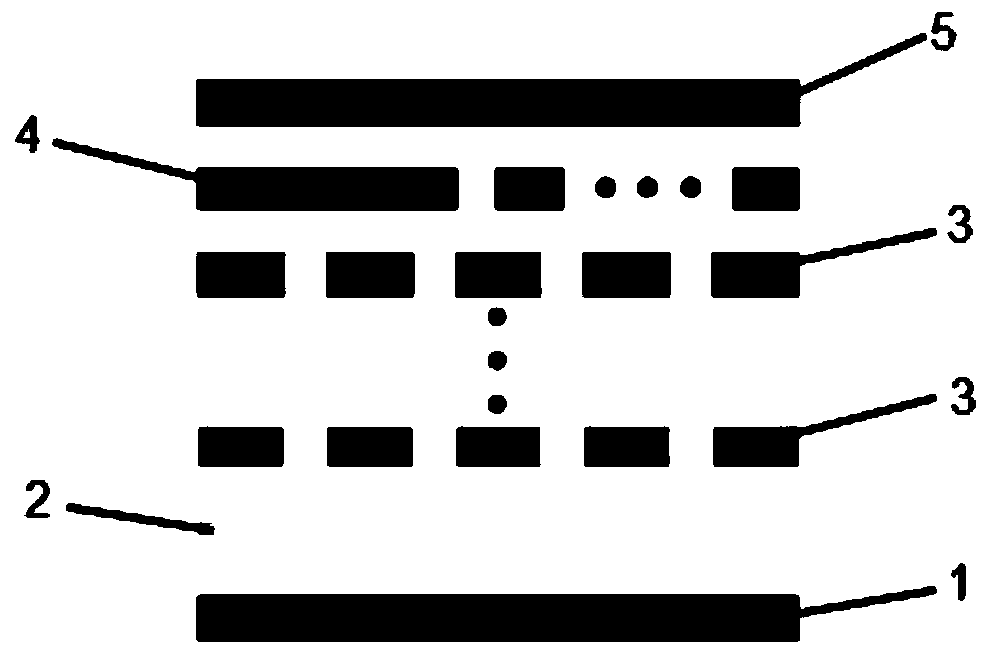

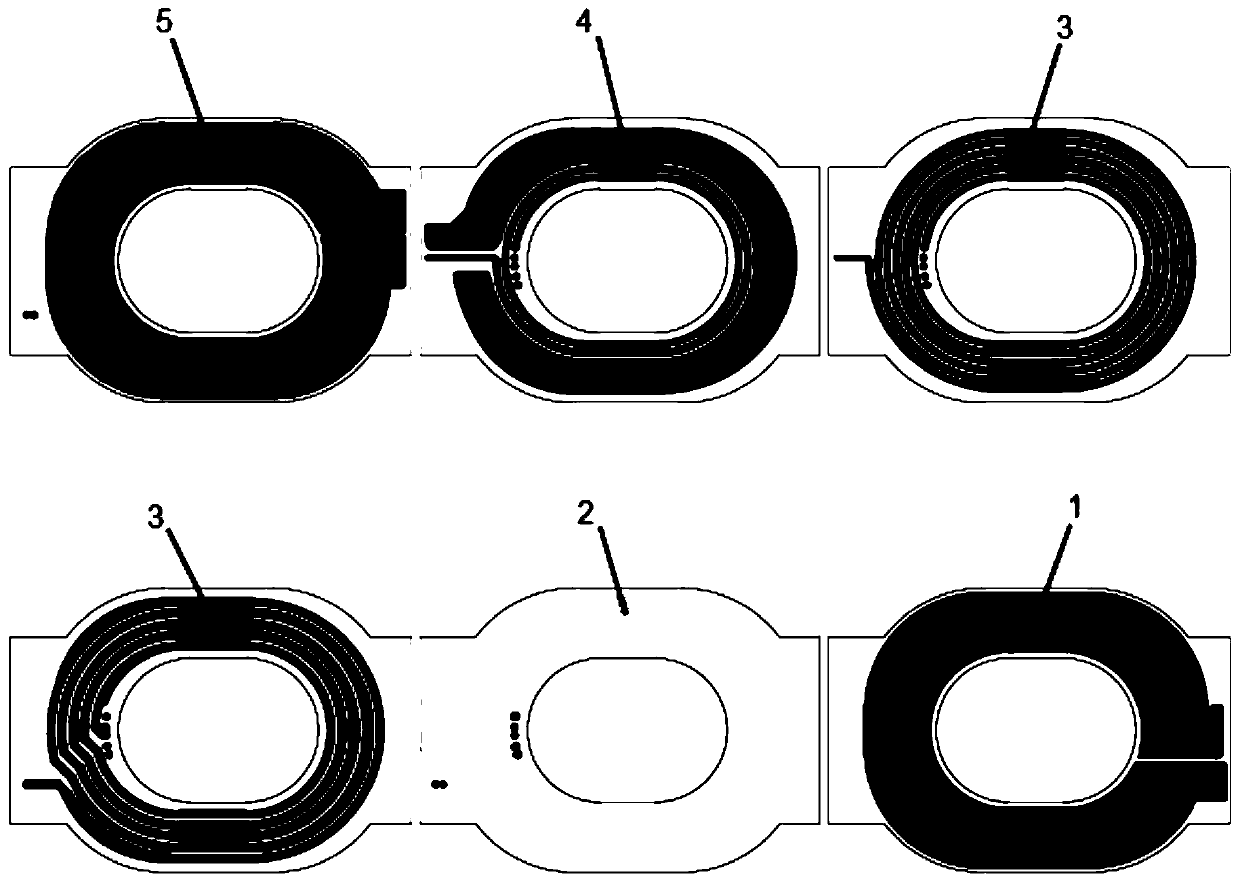

[0036] see figure 1 , this embodiment provides a planar transformer, which is a sub-primary structure. output power specifications, the top shielding layer 4 and the bottom shielding layer 2 can be connected in series or in parallel, the middle layer is between the bottom and top layer coils, the middle layer can be a multi-layer structure, and the planar transformer can have a 6-14-layer structure as a whole ,Such as figure 2 It is a schematic diagram of the 6-layer structure.

[0037] The bottom-level coil 1 starts from the secondary static point potential and is wound clockwise or counterclockwise; the winding direction of the top-level coil 5 is the same as that of the bottom-level coil 1 .

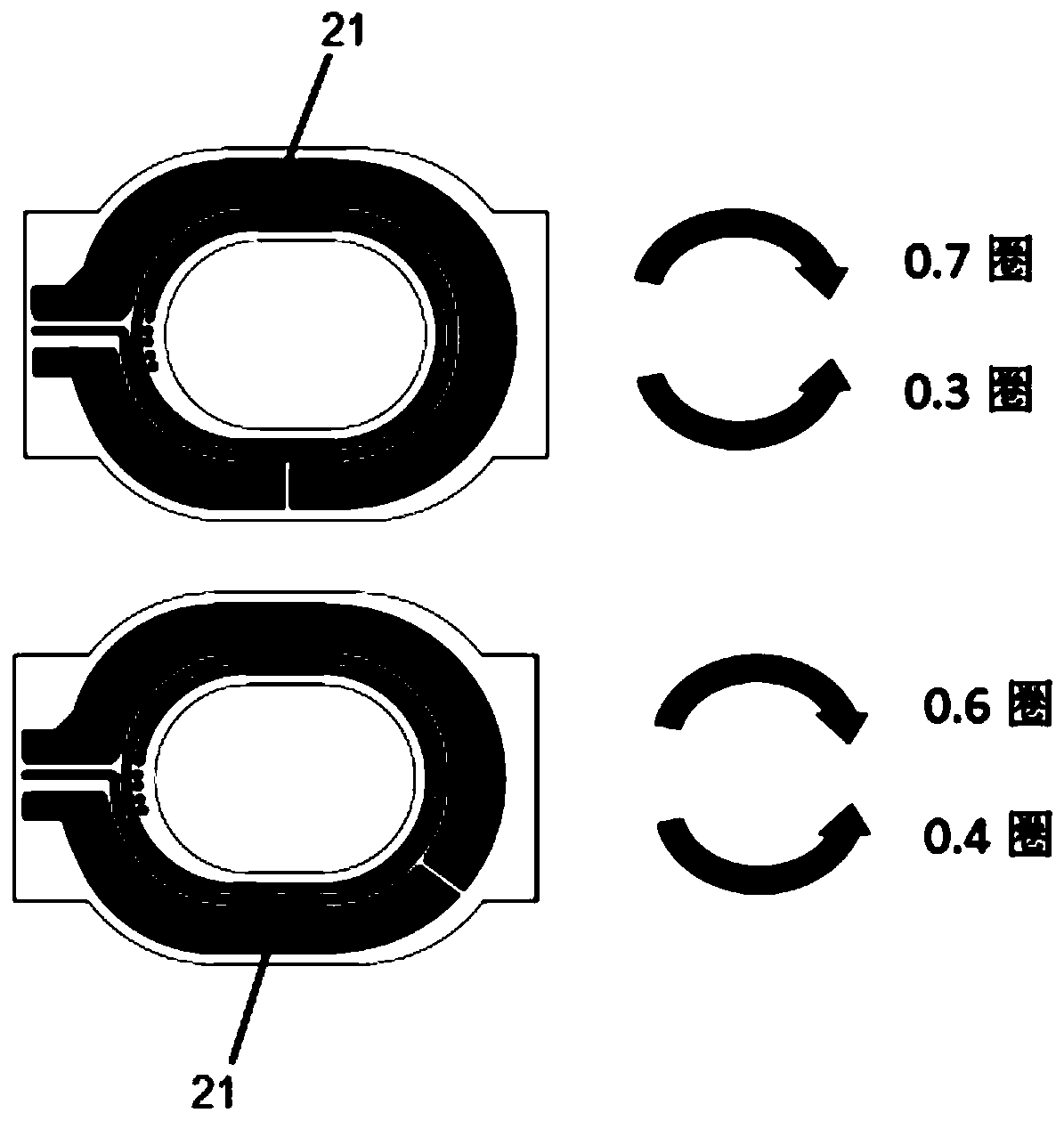

[0038] Wherein, the top shielding layer 4 and the bottom shielding layer 2 both include shielding coils 21, and at least one shielding coil 21 in the top shielding layer 4 and the bottom shielding layer 2 includes N1 clockwise coils and N2 counterclockwise coils, the The sum of N1...

Embodiment 2

[0045] see Figure 6 , the present embodiment provides a planar transformer, the difference from Embodiment 1 is that the top shielding layer 4 and / or the bottom shielding layer 2 also includes a first auxiliary winding 22, and the top shielding layer 4 and / or the bottom shielding layer 2 includes N3 clockwise shielding coils 21 and N4 anticlockwise first auxiliary windings 22, N4 greater than 3, by adjusting the combination of the forward and reverse ratio of the shielding layer and the first auxiliary winding 22 and the copper platinum area of the shielding layer, the best EMI performance is achieved. According to different output specifications, the ratio can be 2 / 6 or 1.5 / 6, or other more ratios.

[0046]In this embodiment, the inner circle of the N3 clockwise shielding coil 21 is provided with N4 counterclockwise first auxiliary windings 22 , wherein N3 is greater than 1.

[0047] The area of the N3 clockwise shielding coil and the value of N3 can be changed to adjus...

Embodiment 3

[0050] This embodiment provides a planar transformer. On the basis of the first embodiment, an auxiliary winding is added to the inner circle of the shielding coil and designed on the same layer to reduce the total layer thickness and reduce the cost.

[0051] Such as Figure 7 , Figure 8 As shown, the bottom shielding layer 2 further includes a second auxiliary winding 23 , and the second auxiliary winding 23 is arranged on the inner coil of the shielding coil of the bottom shielding layer 2 .

[0052] or as figure 1 , Figure 9 As shown, the top shielding layer 4 also includes a second auxiliary winding 23 , and the second auxiliary winding 23 is arranged on the inner coil of the shielding coil of the top shielding layer 4 .

[0053] or as Figure 10 , Figure 11 As shown, both the bottom shielding layer 2 and the top shielding layer 4 include a second auxiliary winding 23 , and the second auxiliary winding 23 is arranged in the inner circle of the shielding coil of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com