A negative pressure automatic defrosting system and method thereof

A negative pressure and automatic defrosting technology, which is applied in defrosting, household refrigeration equipment, lighting and heating equipment, etc., can solve the problems of high energy consumption of periodic automatic defrosting, complicated defrosting system structure, and determination of the starting point of defrosting process Incomplete technology and other problems, to achieve the effect of a reasonable and complete negative pressure automatic defrosting system, improve storage quality, and reduce loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

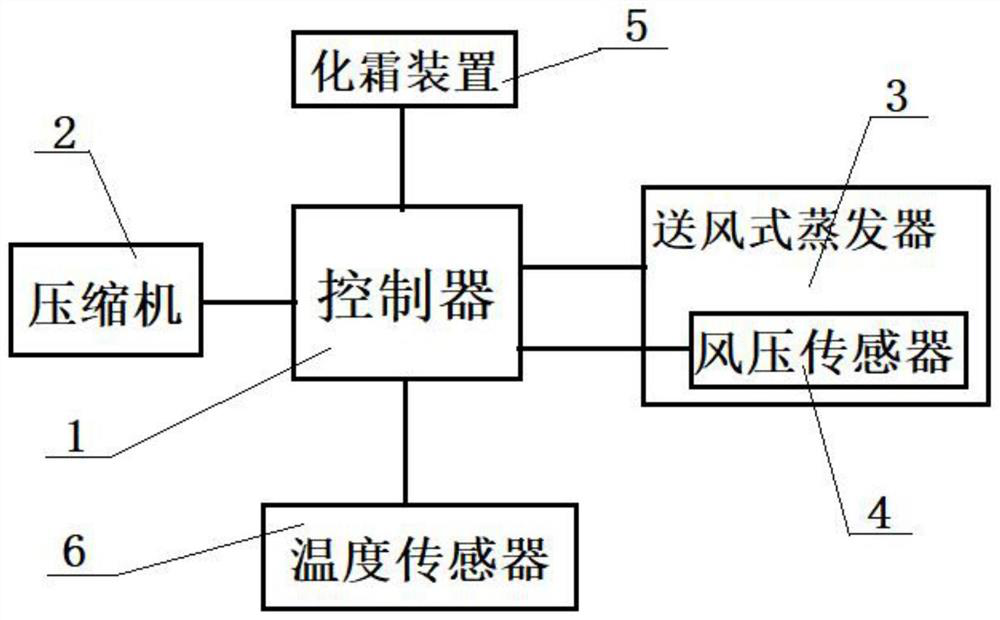

[0069] The negative pressure automatic frosting system involved in this embodiment has a main structure including a controller 1, a compressor 2, an air-supply evaporator 3, a wind pressure sensor 4, a defrosting device 5 and a temperature sensor 6; There is an equipment controller structure. The controller 1 is installed outside the cold storage room. The controller 1 is connected to the compressor 2, the air supply evaporator 3, the wind pressure sensor 4 and the temperature sensor 6 respectively. Inside the shell of the air-type evaporator 3, the air pressure sensor 4 is used to detect the air pressure value in the air-supply evaporator 3; the controller 1 is electrically connected with the defrosting device 5, and the controller 1 is electrically connected with the power supply to defrost The device 5 adopts the existing defrosting equipment, and the operation of the whole system is automatically controlled by the controller 1 .

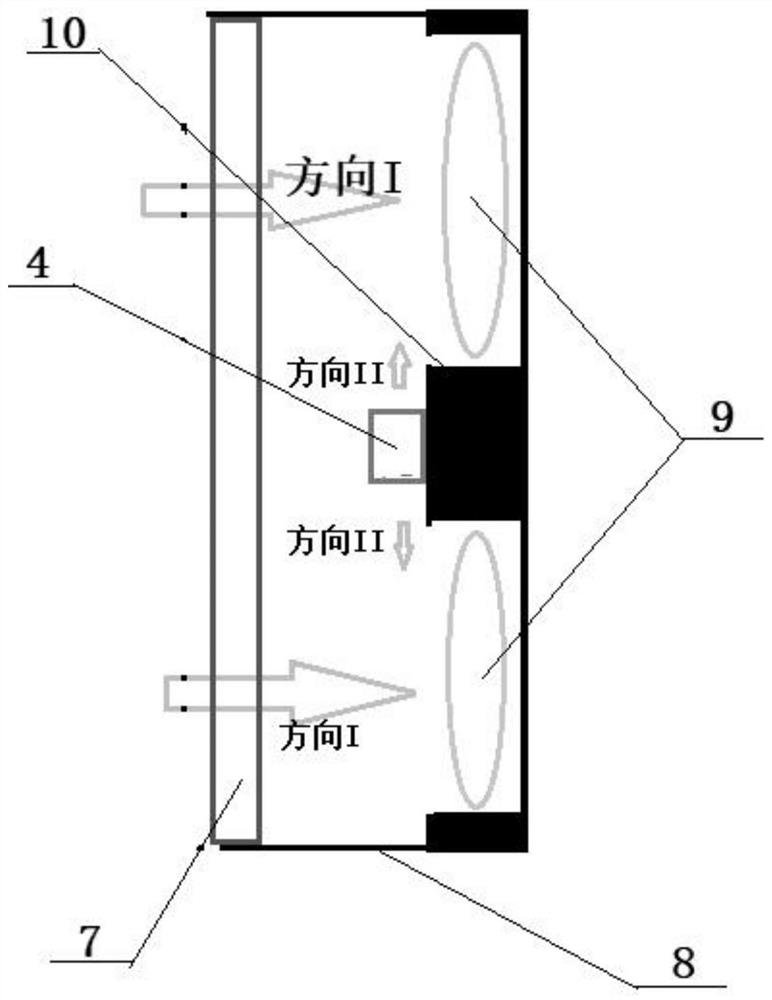

[0070] The air-supply evaporator 3 involve...

Embodiment 3

[0104] A specific automatic frosting method using the negative pressure automatic frosting system described in Example 1 is:

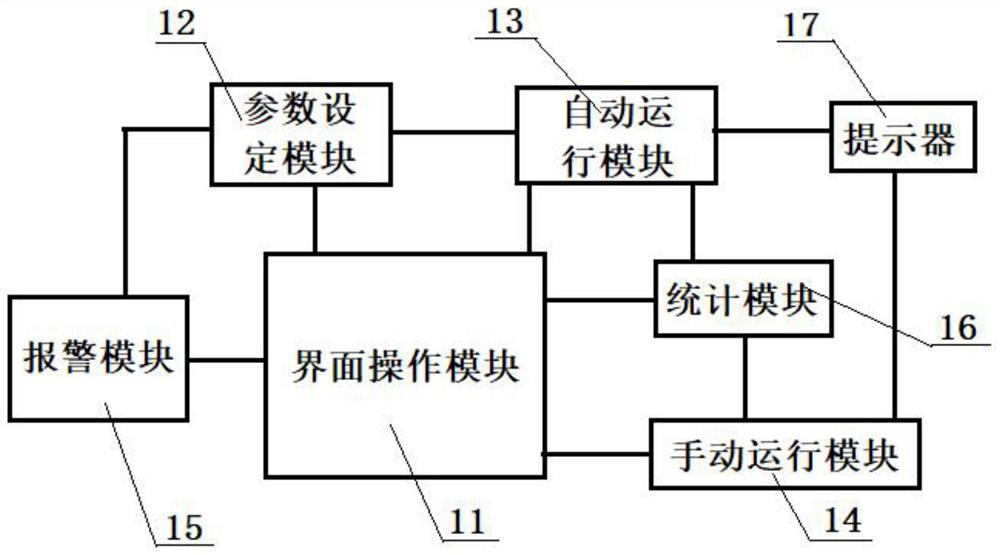

[0105] (1) Press the start key 27 to start the controller 1, press the set key 18 to enter the parameter setting module 12, enter the four-digit password or the initial password 9999 to log in to the parameter setting interface, set the parameters of the automatic frost mode, and the defrosting cycle Set it to 48 hours, set the defrosting air volume to 70Kpa, set the defrosting time to 30 minutes, set the defrosting stop temperature to 0°C, set the defrosting delay to 1 minute, and set the delay after defrosting to 5 minutes, the evaporator delay is set to 1 minute, the compressor delay is set to 1 minute, the power failure start delay is set to 1 minute, the sensor interruption time is set to 10 seconds, and the frosting amount is set to 30% , the temperature range value is 4°C and the temperature rise value is 2°C, and the set parameters are sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com