A Dynamic Weighted Heuristic Scheduling Method for Automatic Manufacturing System

An automatic manufacturing system and heuristic scheduling technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems that the automatic manufacturing system is not applicable and the depth cannot be predicted in advance, so as to speed up the calculation and analysis of the model , Accelerate the acquisition speed, and seek the effect of accelerating the acquisition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

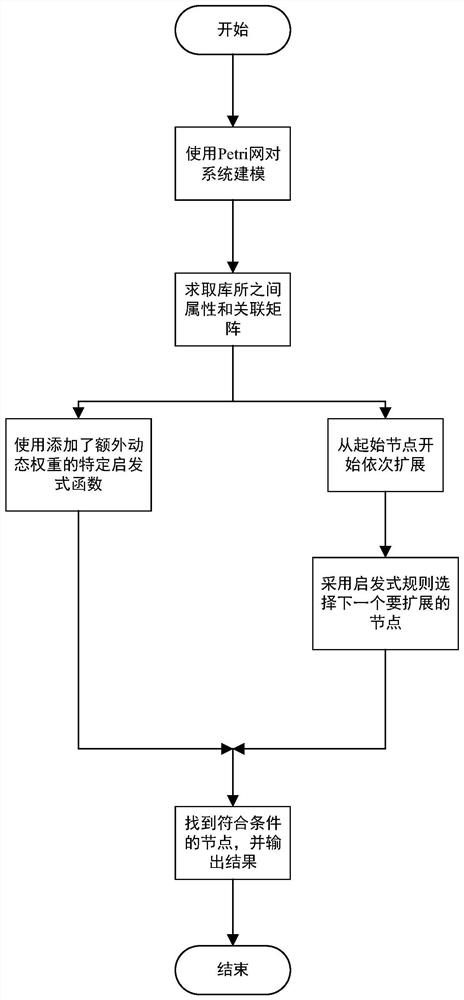

[0077] The dynamic weighted heuristic scheduling method of the automatic manufacturing system of the present invention includes the following contents:

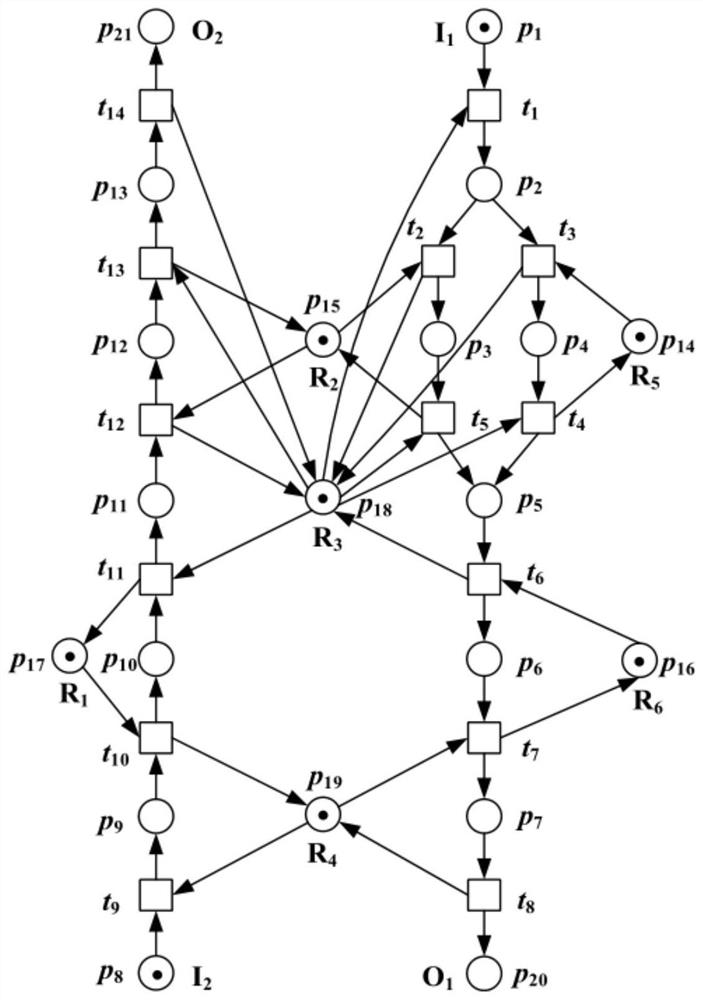

[0078] 1. Use the Petri net to model an automatic manufacturing system, and obtain the Petri net model such as figure 2 shown.

[0079]2. Read the data values corresponding to each library in the Petri net model established in the above 1, and further obtain the correlation matrix between the library places and transitions in the Petri net model according to the read data values.

[0080] The data value of the init file obtained in this example is:

[0081]

[0082] The association matrix of the matrix file in this embodiment is:

[0083]

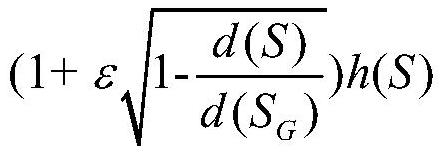

[0084] 3. Based on the association matrix and heuristic A* search algorithm of the above 2, starting from the starting node S 0 Starting to expand the child nodes until all the target nodes are found, that is, the dynamic weighted heuristic search of the system is completed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com