A method and system for pressing tobacco sheets with a four-roll press

A technology of tobacco sheet and rolling press, which is applied in the fields of tobacco preparation, tobacco, application, etc., can solve the problems of mechanical gear wear, gap value deviation, affecting the overall thickness of the sheet, etc., and achieves the effect of precise pressing and avoiding errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

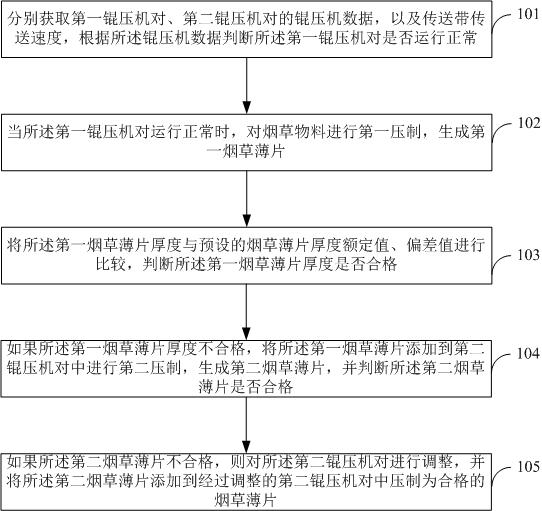

[0040] Such as figure 1 Shown is a flow chart of a method for pressing tobacco sheets with a four-roll press according to an embodiment of the present invention, including:

[0041] Step S101, obtain the roller press data of the first pair of roller presses and the second pair of roller presses, and the conveying speed of the conveyor belt respectively , judging whether the first roller press pair is operating normally according to the roller press data, the roller press data includes: the first roller press pair spacing rating , The deviation value of the pitch of the first roller press , The actual value of the distance between the first roller press , The running speed of the first roller press pair , The running speed of the second roller press pair .

[0042] In the embodiment of the present invention, every two roller presses form a pair of roller presses, and there is a gap in the middle of the roller press pairs, and the tobacco material is extruded into tob...

Embodiment 2

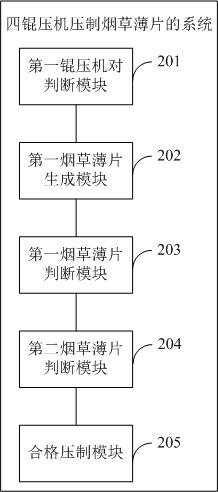

[0064] Such as figure 2 Shown is a structural diagram of a system for pressing tobacco sheets with a four-roller press according to an embodiment of the present invention, and the system includes:

[0065] The first roller press pair judging module 201 is used to obtain the roller press data of the first roller press pair and the second roller press pair respectively, and the transmission speed of the conveyor belt , judging whether the first roller press pair is operating normally according to the roller press data, the roller press data includes: the first roller press pair spacing rating , The deviation value of the pitch of the first roller press , The actual value of the distance between the first roller press , The running speed of the first roller press pair , The running speed of the second roller press pair .

[0066] In the embodiment of the present invention, every two roller presses form a pair of roller presses, and there is a gap in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com