Granular grain dust removal device

A technology of dust removal device and grain, which is applied in the direction of solid separation, separation of solid from solid by air flow, chemical instrument and method, etc., can solve the problems of adding dust, grain is damaged by buyers, illegal interests, etc., and achieves a simple structure. , Convenient vehicle transportation, obvious effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings.

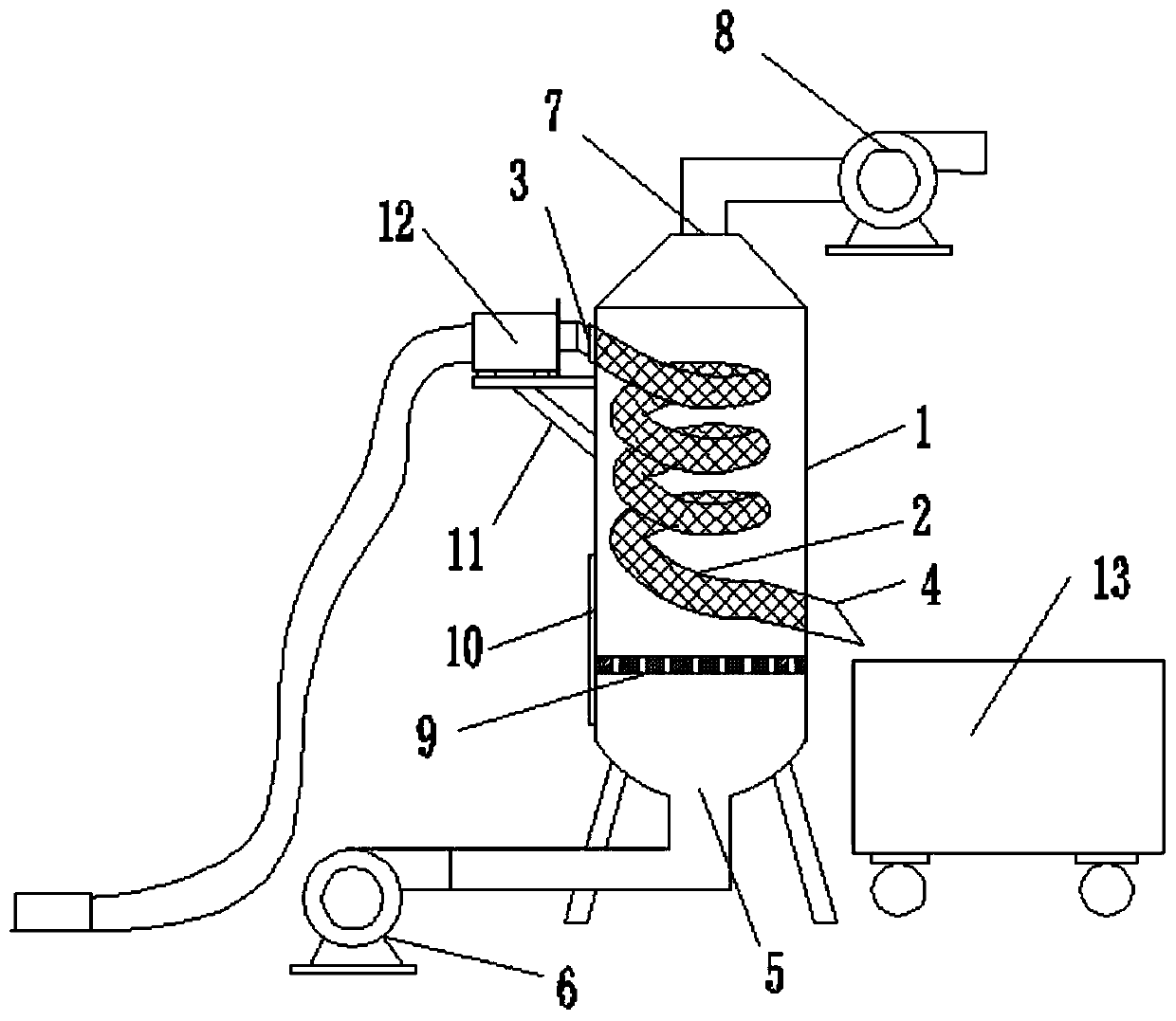

[0015] A dust removal device for granular grains includes a cylinder body 1. A dust removal filter screen 2 is ringed from top to bottom inside the cylinder body 1. The top end of the dust removal filter screen 2 is provided with an inlet 3 that extends out of the cylinder body 1. The bottom end of the dust filter 2 is provided with an outlet 4, the outlet 4 extends out of the cylinder 1, and the bottom of the cylinder 1 is provided with an air inlet 5, and the air inlet 5 is connected with a blower 6 through a pipe, The top of the cylinder 1 is provided with an air outlet 7, the air outlet 7 is connected with an exhaust fan 8, and the inside of the cylinder 1 is located on the upper side of the air inlet 5 with a flow-sharing plate 9.

[0016] The ventilating holes are evenly distributed on the flow sharing plate 9.

[0017] A maintenance door 10 is opened on one side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com