Wall-mounted clothes processing equipment

A kind of clothing processing equipment, wall-mounted technology, applied in other washing machines, household dryers, textiles and paper making, etc., can solve the problems of connection failure, affecting the appearance of equipment, damaging the door body, etc., and achieve the effect of improving the contact environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

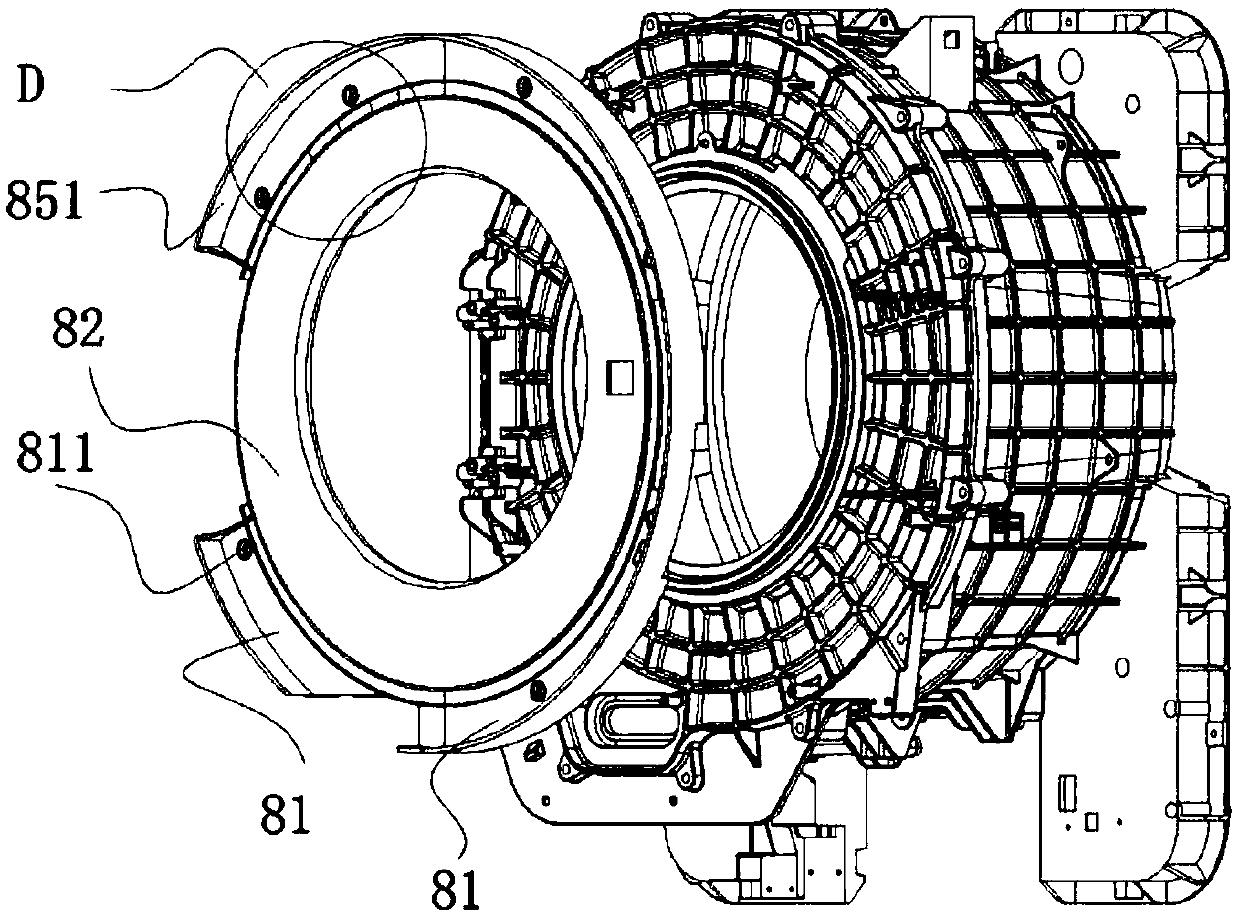

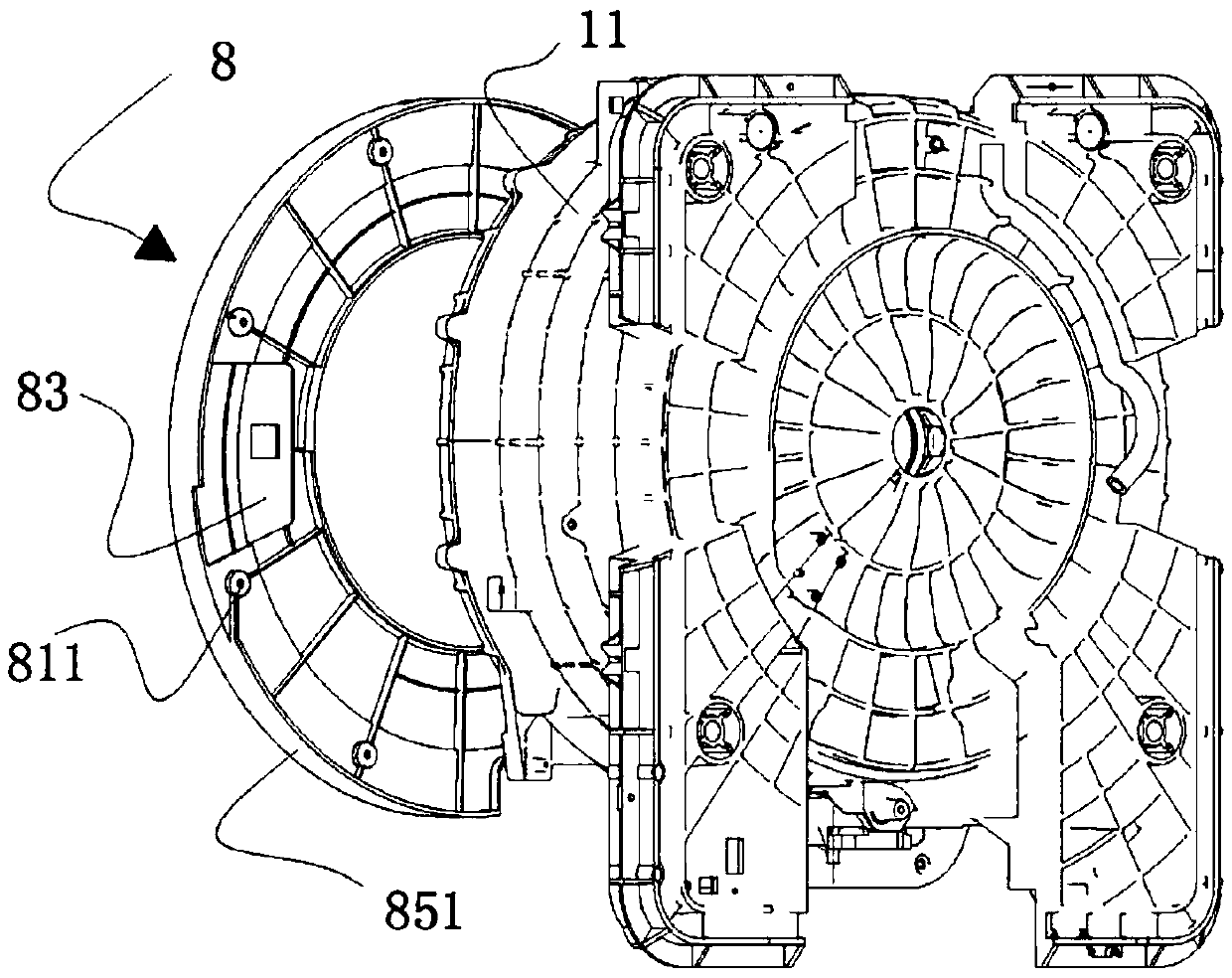

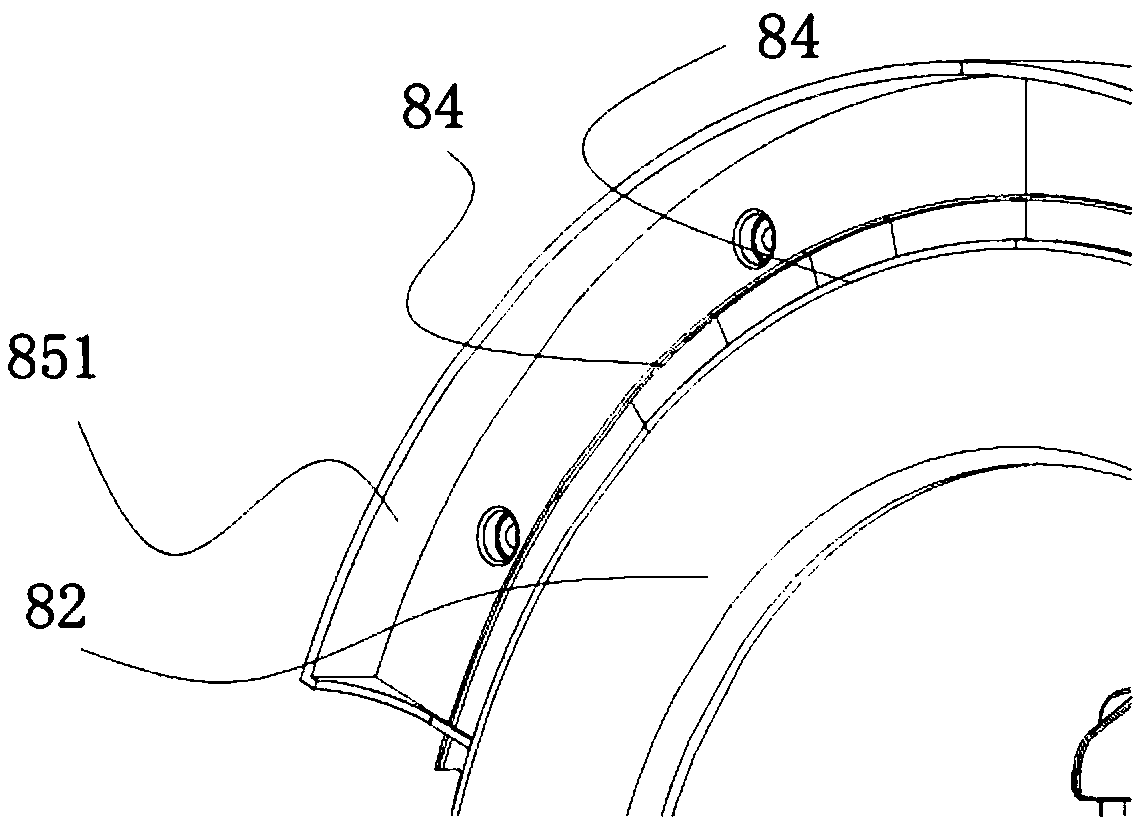

[0043] Such as Figure 1 to Figure 3 As shown, the wall-mounted laundry processing equipment described in this embodiment includes a door body, which is directly connected to the barrel body 11 and can cover the laundry insertion port; the cover part 82 is an annular structure, and the door When the body is closed, it abuts against the door body. The connecting portion 81 is an arc-shaped structure and is disposed along at least part of the outer peripheral side of the cover portion 82 . Preferably, the number of the connecting parts 81 is at least two. According to the wall-mounted laundry processing equipment introduced in this embodiment, the connecting part is a non-connecting structure, and only the part that needs to realize the connecting function forms an arc-shaped structure. This structural design can provide space for the installation of other components. There may be multiple arc-shaped structures, and the sizes of the multiple arc-shaped structures may be set to...

Embodiment 2

[0045] Such as Figure 1 to Figure 3As shown, the difference between the wall-mounted laundry treatment device in this embodiment and the above-mentioned embodiments is that the wall-mounted laundry treatment device includes a lock for locking the connection between the door body and the front panel, and the front panel A mounting groove 83 for accommodating the lock is provided at a position corresponding to the lock on the side of the cover facing the barrel body 11 . The installation groove 83 is provided on the premise of not affecting the flatness of the front cover towards the side of the door body. The front cover in this embodiment can be a structure with a certain thickness, so it can wrap the lock in at least two directions. Since the front cover itself has the function of anti-shock, this design can also play a certain role in protecting the lock. The installation groove can be arranged at the position of the cover part, can also be arranged at the position of the...

Embodiment 3

[0048] Such as Figure 1 to Figure 3 As shown, the difference between the wall-mounted laundry processing device described in this embodiment and the above-mentioned embodiments is that: the wall-mounted laundry processing device includes a hinge for realizing a pivotable connection between the bucket body and the door body, so The part of the connecting part 81 relative to the hinge is a discontinuous structure. Since the hinge is at least part of the movable part, and at least part of the movable part needs to be connected with the door body, then the connection part relative to the hinge position is set as a vacant structure, which can realize the contact between the hinge and the door body, and is the pivot of the hinge. Turn movement provides space. Further, the front cover 8 in this embodiment is designed as a partially vacant structure for the connecting portion 81, because in actual use, the connecting portion 81 is covered by other components and will not be seen by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com