Non-woven fabric for hygienic products, manufacturing method and application of non-woven fabric

A technology of hygienic products and non-woven fabrics, which is applied in the field of non-woven fabrics for manufacturing and hygienic products. It can solve the problems of increased slippage and back seepage, and the inability of urine to spread horizontally, achieving less back seepage, Improve the contact environment and reduce the effect of back seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

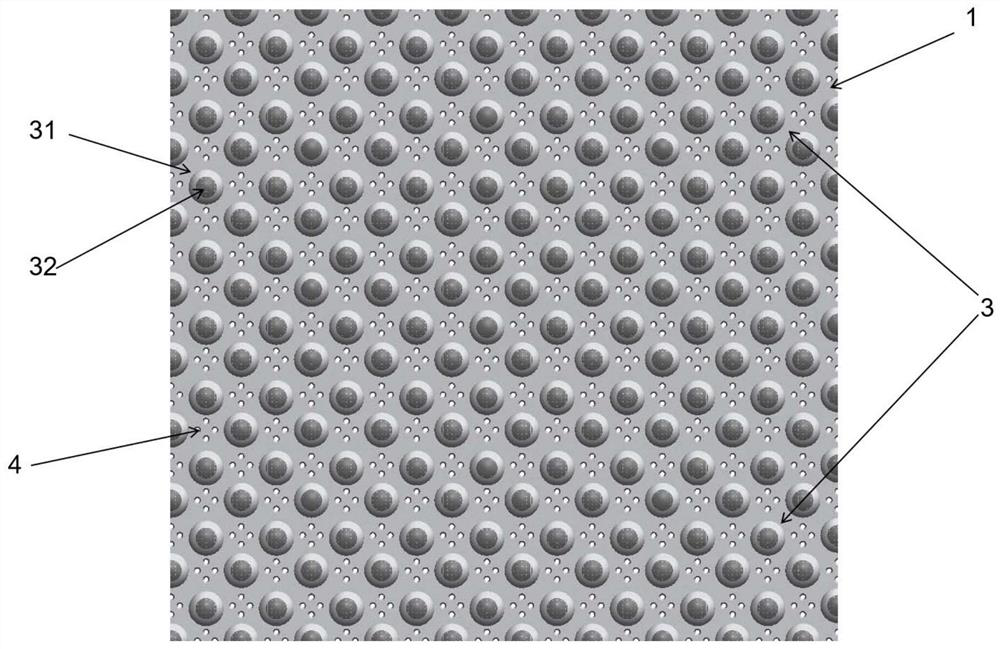

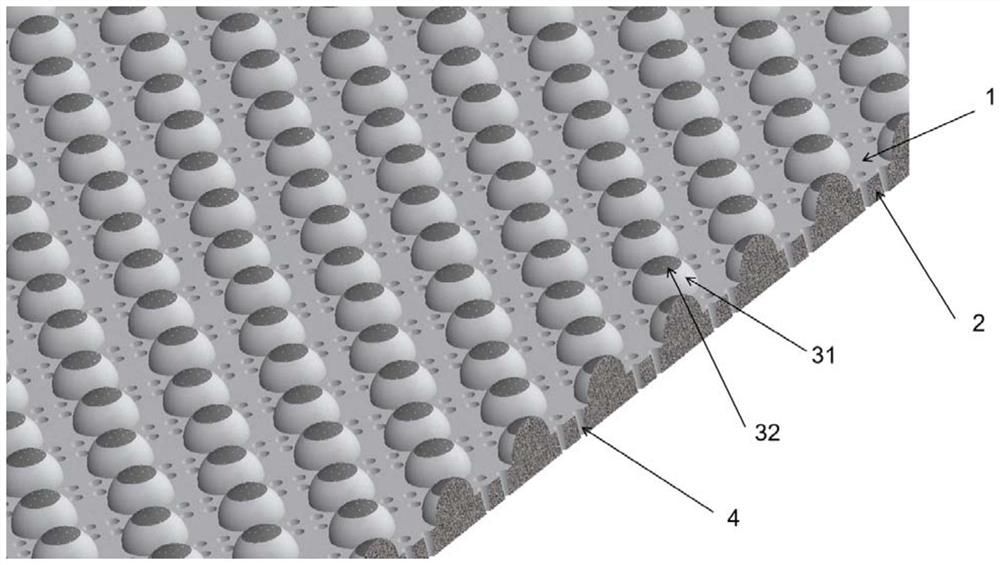

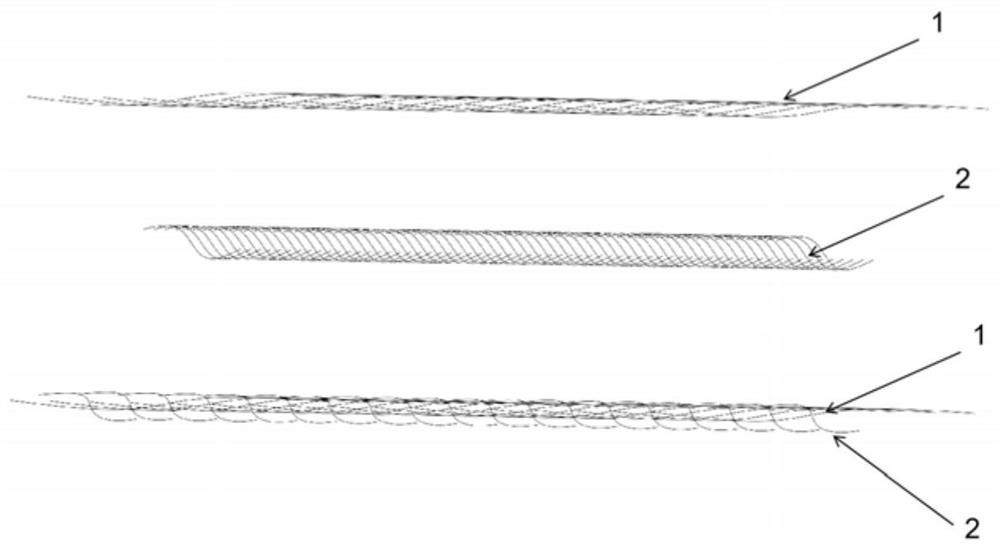

[0030] A non-woven fabric for hygiene products, the non-woven fabric comprises a first layer of non-woven fabric 1 and a second layer of non-woven fabric 2, the first layer of non-woven fabric 1 is made by mixing and blending PET fibers and PE fibers , the fiber orientation is in the horizontal direction, the fiber fineness is 1.5D, and the thickness of the non-woven fabric is 0.15cm; the second layer of non-woven fabric 2 is made by mixing PET fibers and PE fibers after crimping, the fiber fineness is 1.0D, and the non-woven fabric The thickness is 0.3cm; the crimped fiber head in the second layer of non-woven fabric 2 intersects with the horizontal fibers in the first layer of non-woven fabric 1, and the crimped fiber tails in the second layer of non-woven fabric 2 intersect with the first layer of non-woven fabric The horizontal fibers in the cloth 1 are reversed to form a vertical orientation; the non-woven fabric is provided with X-shaped intersecting prismatic stripes 3 w...

Embodiment 2

[0038] A non-woven fabric for hygiene products, the non-woven fabric comprises a first layer of non-woven fabric 1 and a second layer of non-woven fabric 2, the first layer of non-woven fabric 1 is made by mixing and blending PET fibers and PE fibers , the fiber orientation is in the horizontal direction, the fiber fineness is 3.0D, and the thickness of the non-woven fabric is 0.15cm; the second layer of non-woven fabric 2 is made by mixing PET fibers and PE fibers after crimping, the fiber fineness is 2.0D, and the non-woven fabric The thickness is 0.3cm; the crimped fiber head in the second layer of non-woven fabric 2 intersects with the horizontal fibers in the first layer of non-woven fabric 1, and the crimped fiber tails in the second layer of non-woven fabric 2 intersect with the first layer of non-woven fabric The horizontal fibers in the cloth 1 are reversed to form a vertical orientation; the non-woven fabric is provided with X-shaped intersecting prismatic stripes 3 w...

Embodiment 3

[0041] A non-woven fabric for hygiene products, the non-woven fabric comprises a first layer of non-woven fabric 1 and a second layer of non-woven fabric 2, the first layer of non-woven fabric 1 is made by mixing and blending PET fibers and PE fibers , the fiber orientation is in the horizontal direction, the fiber fineness is 1.5D, and the thickness of the non-woven fabric is 0.15cm; the second layer of non-woven fabric 2 is made by mixing PET fibers and PE fibers after crimping, the fiber fineness is 1.0D, and the non-woven fabric The thickness is 0.3cm; the crimped fiber head in the second layer of non-woven fabric 2 intersects with the horizontal fibers in the first layer of non-woven fabric 1, and the crimped fiber tails in the second layer of non-woven fabric 2 intersect with the first layer of non-woven fabric The horizontal fibers in the cloth 1 are reversed to form a vertical orientation; the non-woven fabric is provided with X-shaped intersecting prismatic stripes 3 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com