Trackball seat and trackball mounting and supporting structure

A support structure and trackball technology, which is applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems affecting the use effect and appearance, scratches of stainless steel balls, and loud noise of ball rolling, etc. To achieve the effect of convenient production, eliminate surface wear and smooth rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in detail below.

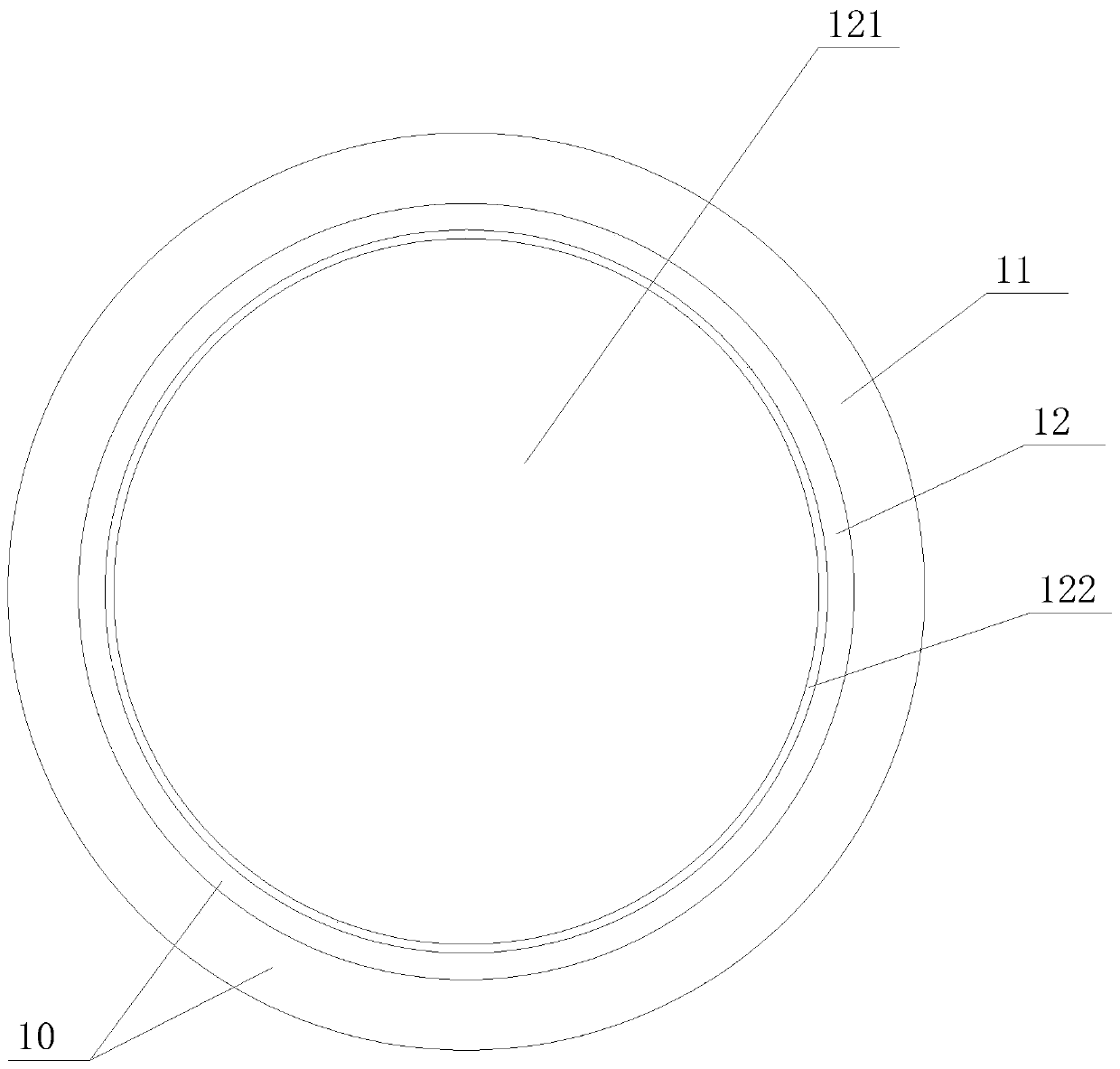

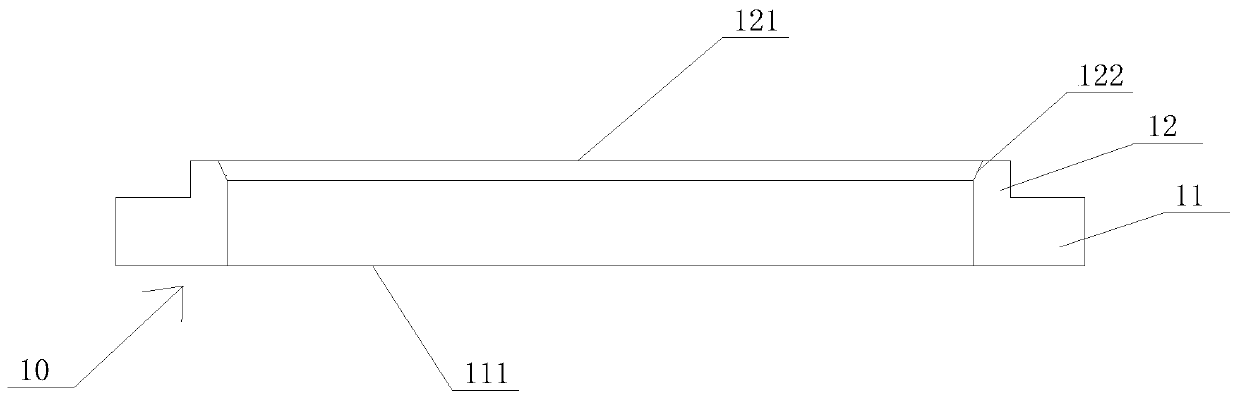

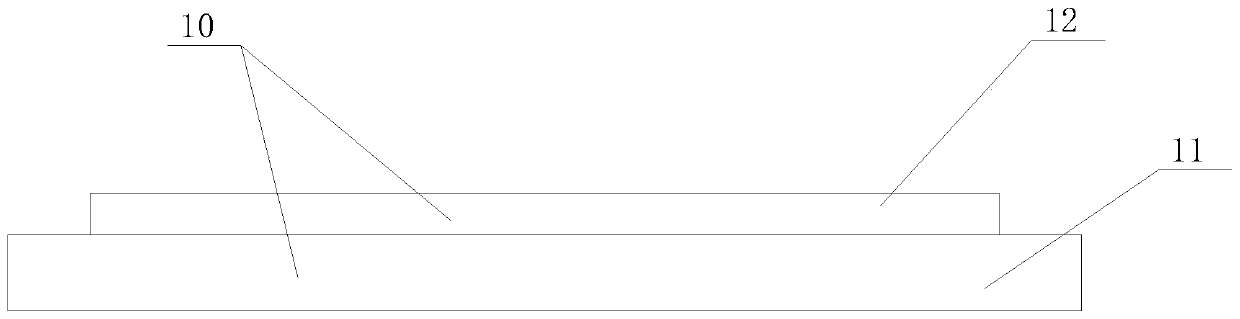

[0043] Such as Figure 1 to Figure 3 As shown, a kind of track ball seat provided by the present invention includes an annular base 11, and the annular base 11 has a first circular through hole 111, and the inner edge of the annular base 11 near the upper end of the first circular through hole 111 is provided with Lubricating support boss 12 is arranged, and lubricating supporting boss 12 is annular, and lubricating supporting boss 12 has support circular through hole 121, and lubricating supporting boss 12 is provided with trumpet-shaped support slope 122 along the inner side of supporting circular through hole 121 upper end.

[0044]During installation and use, the bottom edge of the trackball 20 is protruded downwards below the support circular through hole 121, and the horn-shaped support slope 122 of the lubricated support boss 12 is used to support the trackball 20 to roll, thereby reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com